A clear-cab 2-tanner from LEYLAND

Page 68

Page 69

Page 70

If you've noticed an error in this article please click here to report it so we can fix it.

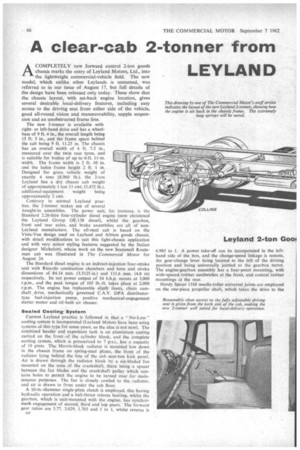

ACOMPLETELY new forward control 2-ton goods chassis marks the entry of Leyland Motors, Ltd., into the lightweight commercial-vehicle field. The new model, which unlike other Leylands is unnamed, was referred to in our issue of August 17, but full details a the design have been released only today. These show that the chassis layout, with set-back engine location, gives several desirable local-delivery features, including easy access to the driving seat from either side of the vehicle, good all-round vision and manceuvrability, supple suspension and an unobstructed frame line.

The new 2-tanner is available with rightor left-hand drive and has a wheelbase of 9 ft. 4 in., the overall length being 15 ft. 5 in., and the frame space behind the cab being 9 ft. 11.25 in. The chassis has an overall width of 6 ft. 7.5 in., measured over the twin rear tyres, and is suitable for bodies of up to 6-ft. 11-in. width. The frame width is 2 ft. 10 in. and the laden frame height 2 ft. 1 in. Designed for gross vehicle weight of exactly 4 tons (8,960 lb.), the 2-ton Leyland has a dry chassis cab weight of approximately 1 ton It cwt. (3,472 lb.),

additional-equipment weight being approximately 2 cwt.

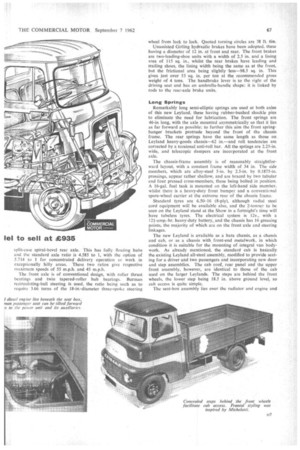

Contrary to normal Leyland practice, the 2-tonner makes use of several bought-in assemblies. The power unit, for instance, is the Standard 2.26-litre four-cylinder diesel engine (now christened the Leyland Group 0E.138 diesel), whilst the gearbox, front and rear axles, and brake assemblies are all of nonLeyland manufacture. The all-steel cab is based on the Vista-Vue design used on Leyland and Albion goods chassis, with detail modifications to suit this light-chassis application and with very minor styling features suggested by the Italian designer lvfichelotti, whose work on the new Scammell Routeman cab was illustrated in The Commercial Motor for August 24.

The Standard diesel engine is an indirect-injection four-stroke unit with Ricardo combustion chambers and bore and stroke dimensions of 84.14 mm. (3.3125 in.) and 111.6 mm. (4.0 in) respectively. Its net power output of 54 b.h.p. occurs at 3,000 r.p.m., and the peak torque of 105 lb.-ft. takes place at 2,000 r.p.m. The engine has replaceable slipfit liners, chain camshaft ,drive, mechanically governed C.A.V. DPA distributortype fuel-injection pump, positive mechanical-engagement starter motor and oil-bath air cleaner.

Sealed Cooling System

Current Leyland practice is followed in that a "No-Loss" cooling system is incorporated (Leyland Motors have been using systems of this type for some years, so the idea is not new). The combined header and expansion tank is an aluminium casting carried on the front of the cylinder block, and the complete cooling system, which is pressurized to 7 p.s.i., has a capacity of 19 pints. The Morris-block radiator is mounted low down in the chassis frame on spring-steel plates, the front of the radiator lying behind the line of the cab seat-box kick panel. Air is drawn through the radiator block by a six-bladed fan mounted on the nose of the crankshaft, there being a spacer between the fan blades and the crankshaft pulley which contains holes to permit the engine to be turned over for maintenance purposes. The fan is closely cowled to the radiator, and air is drawn in from under the cab floor.

A 10-in.-diameter single-plate clutch is employed, this having hydraulic operation and a ball-thrust release bearing, whilst the gearbox, which is unit-mounted with the engine, has synchromesh engagement of second, third and top gears. The forward gear ratios are 5.77, 3.029, 1.703 and 1 to 1, whilst reverse is

D6

6.985 to 1. A power take-off can be incorporated in the lefthand side of the box, and the change-speed linkage is remote, the gear-change lever being located to the left of the driving position and being universally jointed to the gearbox turret. The engine-gearbox assembly has a four-point mounting, with wide-spaced rubber sandwiches at the front, and conical rubber mountings at the rear.

• Hardy Spicer 1310 needle-roller universal joints are employed on the one-piece propeller shaft, which takes the drive to the

split-case spiral-bevel rear axle. This has fully floating hubs and the standard axle ratio is 4.585 to 1, with the option of 5.714 to 1 for concentrated delivery operation or work in exceptionally hilly areas. These two ratios give respective maximum speeds of 55 m.p.h. and 45 m.p.h.

The front axle is of conventional design, with roller thrust bearings and twin tapered-roller hub bearings. Burman recirculating-ball steering is used, the ratio being such as to require 3.66 turns of the 18-in.-diameter three-spoke steering wheel from lock to lock. Quoted turning circles are 38 ft. 6in.

Unassisted Girling hydraulic brakes have been adopted, these having a diameter of 12 in. at front and rear. The front brakes are two-leading-shoe units with a width of 2.5 in. and a lining area of 115 sq. in., whilst the rear brakes have leading and trailing shoes, the lining width being the same as at the front, but the frictional area being slightly -less-98.5 sq. in. This gives just over 53 sq. in. per ton at the recommended gross. weight of 4 tons. The handbrake lever is to the right of the driving seat and has an umbrella-handle shape: it is linked by rods to the rear-axle brake units.

Long Springs

Remarkably long semi-elliptic springs are used at both axles of this new Leyland, these having rubber-bushed shackle pins to eliminate the need for lubrication. The front springs are 46-in tong, with the axle mounted asymmetrically so that it lies as far forward as possible: to further this aim the front springhanger brackets protrude beyond the front of the chassis frame. The rear springs have the same length as those on Leyland heavy-goods chassis-62 in.—and roll tendencies are corrected by a torsional anti-roll bar. All the springs are 2.25-in. wide, and telescopic dampers are incorporated at the front axle.

The chassis-frame assembly is of reasonably straightforward layout, with a constant frame width of 34 in. The side members, which are alloy-steel 5-in. by 2.5-in. by 0.1875-in. pressings, appear rather shallow, and are braced by two tubular and four pressed cross-members, these being bolted in position. A 16-gal. fuel tank is mounted on the left-hand side member, whilst there is a heavy-duty front bumper and a conventional spare-wheel carrier at the extreme rear of the chassis frame.

Standard tyres are 6.50-16 (8-ply), although radial steel cord equipment will be available also, and the 2-tonner to be seen on the Leyland stand at the Show in a fortnight's time will have tubeless tyres. The electrical system is 12v., with a 121-amp.-hr. heavy-duty battery, and the chassis has 16 greasing points, the majority of which are on the front axle and steering linkages.

The new Leyland is available as a bare chassis, as a chassis and cab, or as a chassis with front-end metalwork, in which condition it is suitable for the mounting of. integral van bodywork. As already mentioned, the standard cab is basically the existing Leyland all-steel assembly, modified to provide seating for a driver and two passengers and incorporating new door and step assemblies. The cab roof, rear panel and the upper front assembly, however, are identical to those of the cab used on the larger Leylands. The steps are behind the front wheels, the lower step being 18.5 in. above ground level, so cab access is quite simple.

The seat-box assembly lies over the radiator and engine and

carries a separate driver's seat (which is adjustable vertically' and longitudinally) and a two-man bench-type passenger seat, which is hinged at the front and can be swung forward to give access to the power unit. For more comprehensive enginemaintenance work, the seat-box side panels may be removed, whilst the driving seat also • can be taken out of the cab. Access to the brake' and clutch master cylinders and to the battery is given by removing the front grille panel.

Cab Details

The cab assembly is fully undersealed, whilst the underside of the engine compartment is treated with a sound-absorbing material, additional insulation being given by rubber floor matting. The usual Leyland facia-panel layout is retained, with a central instrument cluster flanked by glove pockets, and the horn push, direction-indicator and dip switches are stalkmounted on the right side of the steering column. Ventilation is given by a large air inlet at the front of the cab floor, and heating and demisting equipment can be provided at extra cost. A sliding rear window can be incorporated to give a continuous air flow through the cab.

The Leyland 2-tonner, which is to be manufactured by Standard-Triumph International, Ltd., Coventry, will sell in Great Britain for £935 in chassis-cab form. This new move by Leyland Motors, Ltd., will undoubtedly be received with interest by delivery-vehicle operators, particularly as the cab and chassis layout has no exact European equivalent. Furthermore, the introduction of this model suggests that Leyland have started to fill the gap in the range of goods vehicles produced throughout the Group, no 2-ton vehicles having been produced hitherto at any of the Group's factories.

Although offered only for goods bodywork, and not being ideally suited in its present form for light passenger bodies because of the set-back engine, the demand for this type of light passenger chassis could be met fairly simply by moving the engine to the front of the chassis frame. In addition to British interests. Leyland Motors anticipate that their new 2-tonner will be well received on the European mainland also, and have accordingly made arrangements for the model to be • put into high-quantity production.