BRAKING PERFORMANCE

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

It is obvious that, with wheeled vehicles, there are road conditions which rather nullify the mechanical perfection which is being obtained in braking operation, and it will be a long time before we shall be able to control the road conditions in the same way as we are now controlling the application of the retarding forces.

One of the biggest variables in the old days was in the movement of the pedal controls. In order to obtain a satisfactory braking performance on heavy passenger vehicles, overall leverages were generally high, i.e., the mechanical advantage from the pedal to the brake shoes was such that a great deal of travel took place at the pedal for comparatively small movement at the shoes.

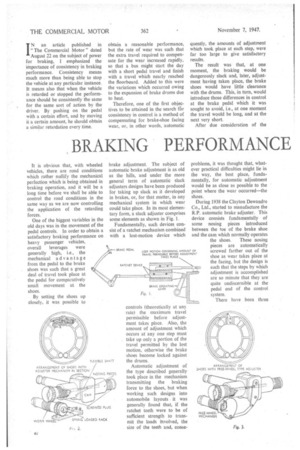

By setting the shoes up closely, it was possible to brake adjustment, The subject of automatic brake adjustment is as old as the hills, and under the more general term of automatic slack adjusters designs have been produced for taking up slack as it developed in brakes, or, for that matter, in any mechanical system in which wear could take place. In its most elementary form, a slack adjuster comprises some elements as shown in Fig. 1.

Fundamentally, such devices consist of a ratchet mechanism combined with a lost-motion device which controls (theoretically at any rate) the maximum travel permissible before adjustment takes place. Also, the amount of adjustment which occurs at any one step must take up only a portion of the travel permitted by the lost motion, otherwise the brake shoes become locked against the drums.

Automatic adjustment of the type described generally took place in the mechanism transmitting the braking force to the shoes, but when working such designs into automobile layouts it was generally found that, if the ratchet teeth were to be of sufficient strength to transmit the loads involved, the size of the teeth and, conse problems, it was thought that, whatever practical difficulties might lie in the way, the best place, fundamentally, for automatic adjustment would be as close as possible to the point where the wear occurred—the shoes.

During 1938 the Clayton Dewandre Co., Ltd., started to manufacture the R.P. automatic brake adjuster. This device consists fundamentally of some nosing pieces introduced between the toe of the brake shoe and the cam which normally operates the shoes. These nosing pieces are automatically screwed farther out of the shoe as wear takes place at the facing, but the design is such that the steps by which adjustment is accomplished are so minute that they are quite undiscernible at the pedal end of the control system.

There have been three