• The first day of January 1993 is E-Day, marking

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

the beginning of free movement of labour, goods and capital among EC member states. Or is it? Brussels would have you believe so, but in practical terms this is hardly the case.

The first of January 1993 is also 1-Day, when higher weights come into force for six and eight-wheelers — which equates to the tipper market. But is this really true? Once again, it's not that simple.

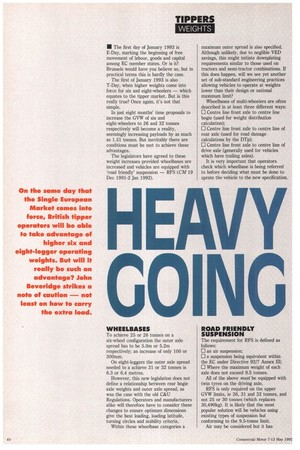

In just eight months' time proposals to increase the GVW of six and eight-wheelers to 26 and 32 tonnes respectively will become a reality, seemingly increasing payloads by as much as 1.51 tonnes. But inevitably there are conditions must be met to achieve these advantages.

The legislators have agreed to these weight increases provided wheelbases are increased and vehicles are equipped with 'road friendly' suspension — RFS (CM 19 Dec 1991-2 Jan 1992).

WIN EELBASES

To achieve 25 or 26 tonnes on a six-wheel configuration the outer axle spread has to be 5.0m or 5.2m respectively; an increase of only 100 or 300mm.

On eight-leggers the outer axle spread needed to a achieve 31 or 32 tonnes is 6.3 or 6.4 metres.

However, this new legislation does not define a relationship between rear bogie axle weights and outer axle spread, as was the case with the old C&U Regulations. Operators and manufacturers alike will therefore have to consider these changes to ensure optimum dimensions give the best loading, loading latitude, turning circles and stability criteria.

Within these wheelbase categories a maximum outer spread is also specified. Although unlikely, due to neglible VED savings, this might initiate downplating requirements similar to those used on tractors and semi-tractor combinations. If this does happen, will we see yet another set of sub-standard engineering practices allowing vehicles to operate at weights lower than their design or national maximum limit?

Wheelbases of multi-wheelers are often described in at least three different ways: 0 Centre line front axle to centre line bogie (used for weight distribution calculation);

El Centre line front axle to centre line of rear axle (used for road damage calculations by the DTp);

0 Centre line front axle to centre line of drive axle (generally used for vehicles which have trailing axles).

It is very important that operators check which wheelbase is being referred to before deciding what must be done to uprate the vehicle to the new specification.

ROAD FRIENDLY SUSPENSION

The requirement for RFS is defined as follows: 0 an air suspension; 0 a suspension being equivalent within the EC under Directive 92/7 Annex III; 0 Where the maximum weight of each axle does not exceed 9.5 tonnes.

All of the above must be equipped with twin tyres on the driving axle.

RFS is only required on the upper GVW limits, ie 26, 31 and 32 tonnes, and not 25 or 30 tonnes (which replaces 30,490kg). It is likely that the most popular solution will be vehicles using existing types of suspension but conforming to the 9.5-tonne limit.

Air may be considered but it has operational problems, while other road-friendly suspension types require a complicated testing procedure and would therefore suffer a cost and certification penalty.

Cutting through the jargon, the RFS regulations apply not only to double-drive vehicles, but also to those trailing-axle designs often favoured by multi-wheeler operators who do little if any off-road work such as bulk grain, brick and home heating oil distribution.

For all axle configurations however, the reality is that the RFS rules cause little change: a "standard" suspension as we know it today is road friendly, provided that each axle does not exceed 9.5 tonnes and the suspension system carries the load equally.

The bogie spread allows an increase of 200kg to 19.00 tonnes provided the axles are at least 1.3m apart.

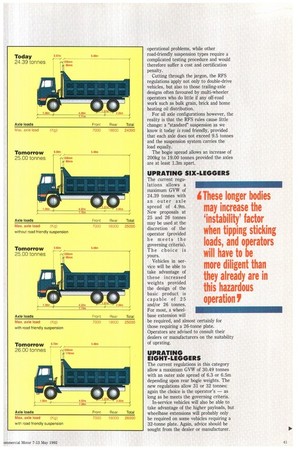

UPRATING SIX-LEGGERS

The current regulations allows a maximum GVW of 24,39 tonnes with an outer axle spread of 4.9m. New proposals at 25 and 26 tonnes may be used at the discretion of the operator (provided he meets the governing criteria). The choice is yours.

Vehicles in service will be able to take advantage of these increased weights provided the design of the basic product is capable of 25 and/or 26 tonnes. For most, a wheelbase extension will be required, and almost certainly for those requiring a 26-tonne plate. Operators are advised to consult their dealers or manufacturers on the suitability of uprating.

operation I

UPRATING EIGHT-LEGGERS

The current regulations in this category allow a maximum GVW of 30.49 tonnes with an outer axle spread of 6.3 or 6.5m depending upon rear bogie weights. The new regulations allow 31 or 32 tonnes: again the choice is the operator's — as long as he meets the governing criteria.

1n-service vehicles will also be able to take advantage of the higher payloads, but wheelbase extensions will probably only be required on some vehicles requiring a 32-tonne plate. Again, advice should be sought from the dealer or manufacturer. It is anticipated that operators may well face a new problem here and it all relates to weight distribution. The extra 1.51 tonnes payload at the 32-tonne limit will have to be distributed predominantly over the front two axles, as the new 19-tonne rear bogies allow an increase of only 200kg; therefore 1.31 tonnes more must be carried by the front axles. To achieve this on existing vehicles the body length would have to be extended forward, resulting in the deletion of front-end tipping rams and the introduction of underfloor gear. These longer bodies may increase the instability factor when tipping sticking loads, so operators will have to be even more diligent than they already are in this hazardous operation.

BODIES

Generally speaking, body lengths on six-wheelers (tippers) will remain the same and only the body sidewalls will need to be increased to contain the extra payload. This in the main also applies to aggregate carriers. Other applications, such as tankers, flatbeds and brick carriers, may require greater modifications to ensure optimum suitability.

Body lengths on eight-wheelers (tippers) will require lengthening at the front rather than an increase in body sides. If, as described earlier, underfloor tipping gear is used, then the body floor structure may require modification or re-design.

WATCH POINTS

0 Front axle capacities for six-wheelers at 26 tonnes need to be seven tonnes minimum and this in itself allows no loading latitude. Suitable tyres must also be chosen, such as 12R22.5s or 295/80R22.5s.

0 Eight-wheelers registered after 1 January 1993 will fall into the category of 30, 31 or 32 tonnes depending upon design construction and the new weights and dimensions as described. But be aware that there is no 30.49-tonne category, unlike the six-wheeler at 24.39 tonnes which remains. Wheelbase selection is critical.

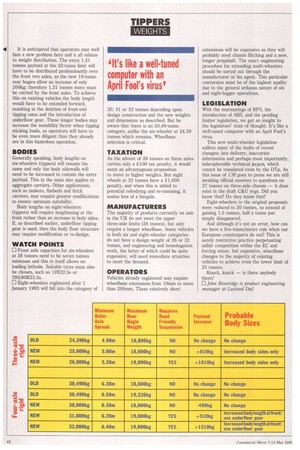

TAXATION

As the advent of 26 tonnes on three axles carries only a £.100 tax penalty, it would seem an advantageous proposition to move to higher weights. But eight wheels at 32 tonnes have a £1,000 penalty, and when this is added to potential rebodying and re-ramming, it seems less of a bargain.

MANUFACTURERS

The majority of products currently on sale in the UK do not meet the upper three-axle limits (26 tonnes), but only require a longer wheelbase. Some vehicles in both six and eight-wheeler categories do not have a design weight of 26 or 32 tonnes, and engineering and homologation work, the latter of which could be quite expensive, will need immediate attention to meet the demand.

OPERATORS

Vehicles already registered may require wheelbase extensions from lOmm to more than 200mm. These relatively short extensions will be expensive as they will probably need chassis ffitching and a new, longer propshaft. The exact engineering procedure for extending multi-wheelers should be sorted out through the manufacturer or his agent. This particular conversion must be of the highest quality due to the general arduous nature of six and eight-legger operations.

LEGISLATION

With the murmurings of RFS, the introduction of ABS, and the pending limiter legislation, we get an insight to the legislators' train of thought. It's like a well-tuned computer with an April Fool's virus.

This new multi-wheeler legislation suffers many of the faults of recent changes: late delivery, inaccurate information and perhaps most importantly, indecipherable technical jargon, which cannot be translated even by the Dip. As this issue of CM goes to press we are still awaiting official answers to questions on 27 tonnes on three-axle chassis — it does exist in the draft C&U regs. Did you know that? Do they know that?

Eight-wheelers in the original proposals were reduced to 30 tonnes, so instead of gaining 1.5 tonnes, half a tonne just simply disappeared.

And although it's not an error, how can we have a five-tonne/metre rule when our European counterparts do not? This is surely restrictive practice perpetuating unfair competition within the EC and forcing minor, but expensive, wheelbase changes to the majority of existing vehicles to achieve even the lower limit of 25 tonnes.

Knock, knock — is there anybody there?

0 John Beveridge is product engineering manager at Leyland Daf