Compact Construction

Page 71

If you've noticed an error in this article please click here to report it so we can fix it.

for

Power Units

A New Double-acting Engine of Unusual Design. Horizontal Mounting Possible

IN the construction of commercial motors one of the first considerations is the question of making the most advantageous use of available space to accommodate the pay-load. in present-day designs the engine occupies, even with forward control, a certain amount of room which might, with advantage, be employed either to give a reduced overall length or to increase the space available for the body.

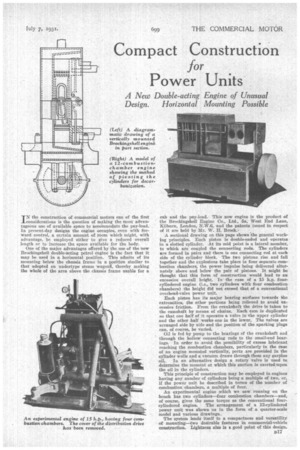

One of the major advantages offered by the use of the new Brockingshell double-acting petrol engine is the fact that it may be used in a horizontal position. This admits of its mounting below the chassis frame in a position similar to that adopted on undertype steam -wagon, thereby making the whole of the area above the chassis frame usable for a cab and the pay-load. This new engine is the product of the Brockingshell Engine Co., Ltd., 5a, West End Lane, Kilburn, London, N.W.G, and the patents issued in respect of it are held by Mr. W. H. Brock.,

A sectional drawing on this page shows the general working principles. Each piston is double-ended and operates in a slotted cylinder. At its mid point is a lateral member, to which are coupled the connecting rods. The cylinders are formed in pairs and there is one connecting rod at each side of the cylinder block. The two pistons rise and fall together and the explosions take place in four separate combustion chambers, the power impulse being delivered alternately above and below the pair of pistons. It might be thought that this form of construction would lead to an excessive overall height, In the case of a 15 h.p. fourcylindered engine (i.e., two cylinders with four combustion chambers) the height did not exceed that of a conventional overhead-valve power unit.

Each piston has its major bearing surfaces towards the extremities, the other portions being relieved to avoid excessive friction. From the crankshaft the drive is taken to the camshaft by means of chains. Each cam is duplicated 80 that one half of it operates a valve in the upper cylinder and the other half works one in the lower. The valves are arranged side by side and the position of the sparking plugs can of course, be varied.

Oil is fed by pump to the bearings of the crankshaft and through the hollow connecting rods to the small-end bearings. In order to avoid the possibility of excess lubricant reaching the combustion chambers, particularly in the case of an engine mounted vertically, ports are provided in the cylinder walls and a vacuum draws through them any surplus

oil. In an alternative design a rotary valve is used to determine the moment at which this suction is exerted ,upon the oil in the cylinders.

This principle of construction may be employed in engines having any number of cylinders being a multiple of two, or, if the power unit be described in terms of the number of combustion clambers, a multiple of four.

An experimental engine which we saw running on the bench has two cylinders—four combustion chambers—and, of course, gives the same torque as the conventional four cylindered engine. The arrangement of a 12-cylindered Power unit was shown us in the form of a quarter-scale model and various drawings..

The system lends itself to a compactness and versatility of mounting—two desirable features in commercial-vehicle construction. Lightness also is a good point of this design.: D17