A COMPREHENSIVE

Page 103

If you've noticed an error in this article please click here to report it so we can fix it.

Specialized

PISTON SERVICE

How the Manufacturer of B.H.B. Pistons is Organizing a Scheme Whereby Replacements of Original Quality can be Bought from Stock

FOR many years the Automotive Engineering Co., Ltd., The Green, Twickenham, Middlesex, has been supplying its well-known B.H.B. pistons to a large number of manufacturers in the commercialmotor and motorcar industry.

At the works an extensive stores has recently been constructed and pistons of all types are grouped ready for immediate dispatch. They are stocked in standard sizes and , various oversizes. In certain Instances as many as four oversizes are kept ready and they can be dispatched With or without gudgeon pins, gudgeon-pin-retaining devices and rings.

The B.H.B. form of piston is made in an alloy known as Hiduminium and is designated R.R.53. This maker holds a licence for the exclusive use of this material for automobile pistons. The alloy is one of those developed and patented by Rolls Royce, Ltd., particularly for aircraft engine construction. T Is e physical properties and special characteristics of this metal are well known to all engineers, , the most important

point being that Hiduminium R R.53 retains its strength and wearing qualities at -elevated temperatures better than other alloys. Besides this and of the greatest importance for the manufacture of pistons, this alloy possesses antifriction qualities superior to other materials; this the accompanying graph readily shows.

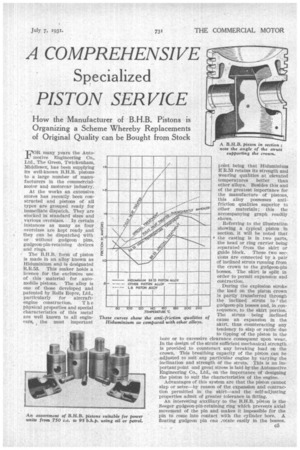

• Referring, to the illustration showing a typical piston In section, it will be noted that • the casting is in twoparts, the head or ring carrier being separated from the skirt or guide block. These two sections are connected by a pair of inclined struts running from the crown to the gudgeon-pin bosses. The skirt is split in order to permit expansion and contraction.

During the explosion stroke the load on the piston crown is partly transferred through the inclined' struts to the gudgeon-pin bosses and, in ,consequence, to the skirt portion. The struts being inclined cause an expansion in the skirt, thus counteracting any tendency to slap or rattle due to tipping of the piston in the bore or to excessive clearance consequent upon wear. In the design of the struts sufficient mechanical strength is provided to counteract any breaking load on the crown. This breathing capacity of the piston can be adjusted to suit any particular engine by varying the inclination and strength of the struts. This is an important point and great stress is laid by the Automotive Engineering Co., Ltd., on the importance of designing the piston to suit the characteristics of the engine.

Advantages of this system are that the piston cannot slap or seize—by reason of the expansion and contraction permitted in the skirt---,and the self-adjusting properties admit of greater tolerance in fitting.

An interesting auxiliary to the B.H.B. piston is the Seeger gudgeon-pin-retaining ring which prevents akial movement of the pin and makes it impossible for the pin to come into contact with the cylinder bore. A floating gudgeon pin can zotate easily in the bosses.