Carrying pigs in new comfort

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

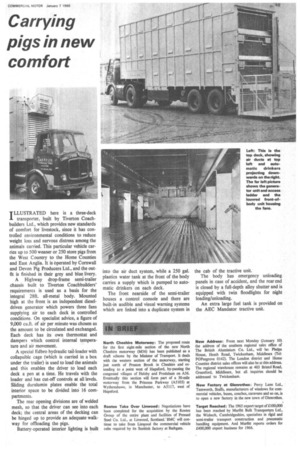

TLLUSTRATED here is a three-deck transporter, built by Tiverton Coachbuilders Ltd., which provides new standards of comfort for livestock, since it has controlled environmental conditions to reduce weight loss and nervous distress among the animals carried. This particular vehicle carries up to 500 weaner or 250 store pigs from the West Country to the Home Counties and East Anglia. It is operated by Cornwall and Devon Pig Producers Ltd., and the outfit is finished in their grey and blue livery.

A Highway drop-frame semi-trailer chassis built to Tiverton Coachbuilders' requirements is used as a basis for the integral 28ft. all-metal body. Mounted high at the front is an independent dieseldriven generator which powers three fans supplying air to each deck in controlled conditions. On specialist advice, a figure of 9,000 cu.ft. of air per minute was chosen as the amount to be circulated and exchanged. Each deck has its own thermostat and dampers which control internal temperature and air movement.

A special Edbro hydraulic tail-loader with collapsible cage (which is carried in a box under the trailer) is used to load the animals and this enables the driver to load each deck a pen at a time. He travels with the loader and has cut-off controls at all levels. Sliding duralumin plates enable the total interior space to be divided into 16 compartments.

The rear opening divisions are of welded mesh, so that the driver can see into each deck; the central areas of the decking can be hinged up to provide an adequate walkway for offloading the pigs.

Battery-operated interior lighting is built into the air duct system, while a 250 gal. plastics water tank at the front of the body carries a supply which is pumped to automatic drinkers on each deck.

The front nearside of the semi-trailer houses a control console and there are built-in audible and visual warning systems which are linked into a duplicate system in the cab of the tractive unit.

The body has emergency unloading panels in case of accident, and the rear end is closed by a full-depth alloy shutter and is equipped with twin floodlights for night loading/unloading.

An extra large fuel tank is provided on the AEC Mandator tractive unit.