The H ppo Likes Hills

Page 38

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

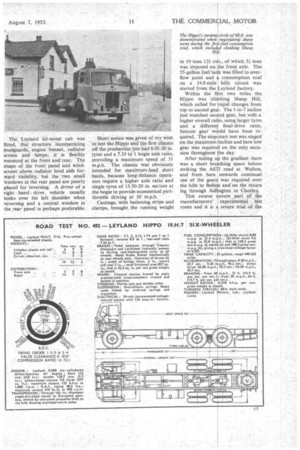

Leyland Six-wheeler Tested Over Hilly Route where Gradients were Climbed with Zest but Without Undue Toll of Fuel: Acceleration and Braking Good

By Laurence J. Cotton,

I

: T is unusual to select a hilly route

to demonstrate the economy of a

six-wheeler loaded to over 19-itons gross, but such was my choice for the Leyland Hippo forward-control chassis which, with continuous gear work over a 35-mile circuit, gave a fuel return of just over 8, m.p.g. • Sheep Hill, near Leyland, which is normally reserved 'as a test climb, was included in the fuel-consumption trial and here the Hippo did well by

negotiating it in second gear. , Most of the components of. the six-wheeler are used also in the 22-ton eight-wheeler. The 9.8-litre direct-injection oil engine fitted is a proven unit of high output which has been chosen by the Road Haulage Executive for use in their Bristol eight-wheeled vehicles.

The 16i-in.-diameter clutch is drilled and slotted for self ventilation and has a flexible centre, thus promoting facing life and ensuring a smooth 'take-up in the transmission. Gear-changing' is foolproof, third, ,fourth and fifth ratios being in constant-mesh, and, apart from second gear, all are reasonably quiet.

The propeller shafts, with Hardy Spicer couplings, transmit the drive to a double-drive bogie, in which both axles are identical in construction and have overhead-worm gear of 9-in. centres. The bogie axles are c2

attached by swivelling trunnions to the ends of semi-elliptic springs, which are in turn mounted on trunnions having a rubber-bush bearing, reducing the need for lubrication or the possibility of hammering, with subsequent wear.

Torque 'reaction is controlled by stout ball-ended tubes linking the bogie axles to the frame. The maximum axle articulation on this unit is about 12 in.

In comparison with all types of vehicle on the road, the six-wheeler, 19 tons gross weight, has, apart from some of the heavier underfloorengined chassis, by far the highest front-axle loading and provides a critical test of steering efficiency. If I were a truck driver, I would prefer to handle an eight-wheeler, which, although carrying more combined weight on the first and second axles, is helped by lower individual tyre loading and by the steering geometry. T h e Hippo's steering ratio of 28.5 to 1 reduces manual effort, but to turn the wheel when shunting still requires strength. .

• Braking effort with 5-in.-wide drums on the centre and rear axles is powerful and light, the pedal operating through a combined Clayton Dewandre servo and Lockheed hydraulic . cylinder to Girling twoleading-Shoe units at all wheels. The multi-pull handbrake is connected to the bogie shoes.

The frame has robust side members 12 in. deep and additional support is provided by inserting a reversed channel section at the bogie pick-up points. A 17-ft. 9-in.wheelbase chassis was tested, the 8-ft. 8-in, overhang from the centre of the bogie extending to the full length of a platform body. The Leyland all-metal cab was fitted, this structure incorporating mudguards, engine bonnet, radiator screen and lamps; it is flexibly mounted at the front and rear. The shape of the front panel and windscreen above radiator level aids forward visibility, but the two small windows in the rear panel are poorly placed for reversing. A driver of a right hand drive vehicle usually looks over his left shoulder when reversing and a central window in the rear panel is perhaps preferable. Short notice was given of my wish to test the Hippo and the first chassis off the production line had 9.06-20 in. tyres and a 7.33 to 1 bogie axle ratio, providing a maximum speed of 31 m.p.h. The chassis was obviously intended for maximum-load short hauls, because long-distance operators require a higher axle ratio and single tyres of 13.50-20 in. section at the bogie to provide economical partthrottle driving at 30 m.p.h.

Castings, with battening strips and clamps, brought the running weight

to 19 tons 124 cwt., of which 51 tons was imposed on the front axle. The 55-gallon fuel tartk was filled to overflow point and 4 consumption trial on a 34.8-mile hilly circuit was started from the Leyland factory.

Within the first two miles the Hippo was climbing Sheep Hill, which called for rapid changes from top to second gear. The 1-in-7 incline just matched second gear, but with a higher overall ratio, using larger tyres and a different final-drive ratio, bottom gear would have been required. The stop-start test was staged on the maximum ,incline and here low gear was required on the only occasion throughout the day.

After toiling up the gradient there was a short breathing space before striking the A675 road at Walton, and from here onwards ,continual use of the gears was required over the hills to BoltOn and on the return leg through Adlington to Cfaorley.

This course covers part of the manufacturers' experimental teSt route and it is a severe trial of the engine and transmission, and perhaps • more so of the braking system. The Smell of well-heated brake facings penetrated through to the cab at frequent intervals.

Considering that the maximum governed speed was 31 m.p.h., the average for the course 21.4 m.p.h., indicates sufficient power and well.-mated gear ratios. When refuelling, 4 gal. 2+ pt. were required before the tank overflowed. This amount corresponds to 8.08 m.p.g.

I then started a second trial tá reproduce an average short-distance haul, involving a proportion of town driving and about two-thirds mainroad work. In 12 miles, 10 pints of fuel were used, affording a return of 9.6 m.p.g. at 22.8 m.p.h., which is reasonably economical for a generous 12-ton load with a low overall ratio,

Acceleration was comparatively fast to 20 m.p.h., but only average to 30 m.p.h., a possible explanation being the low ratios.. At 30 m.p.h. the engine was turning at almost peak revolutions with the torque curve on the wane. To accelerate from rest to 20 m.p.h. occupied 22.1 sec. and to 30 m.p.h. took 46.2 sec. Top-gear acceleration was smooth and swift, 30 m.p.h. being reached from 10 m.p.h. in only 40.7 sec.

With four wide drums at the rear, the brake frictional area is adequate for good deceleration, but this can be spoilt if the braking torque reaction is not properly controlled or if too much weight is transferred to the leading axle of the bogie. The heavy tyre marks left /by all wheels of the Hippo indicated that the braking system and torque reactions were well planned. Average stopping distances of 31 ft. from 20 m.p.h. and 65 ft. from 30 m.p.h. were obtained.

I found little evidence of brake fade through continuecluse, but as a final test I 'made six more trials in rapid succession, from 30 m.p.h., and after the fourth emergency application, the stopping distances remained constant at 72 ft. to 74 ft.

Eighty miles of road work with the Hippo emphasized its solid build, making for confidence in control. With little time delay in the braking system, retardation compares with • that of a medium-class vehicle. Although worked hard during the first consumption test, there was no evidence of overheating in the engine or transmission lubricants and the radiator temperature remained normal.