Longer Life from the Bedford Engine

Page 40

Page 41

Page 42

If you've noticed an error in this article please click here to report it so we can fix it.

Positive Crankcase Ventilation, New Bearing Materials and Other Modifications in Bedford Petrol Engine Make for Higher Efficiency and Longer Life. Change in Carburation Increases Power on "0"-type Models

By L. J. COTTON,

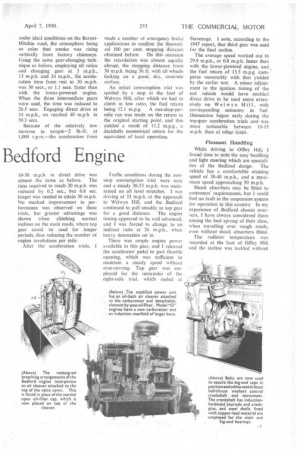

MODIFICATIONS introduced in the Bedford 3,5-litre sixcylindered petrol engine have increased its power output and should improve its life. The bore, stroke and capacity have not been changed, hut the cylinder bores are now precision-finished with a single-point tool and light honing treatment to obviate distortion during machining. The crankshaft .now has induction-hardened journals and crankpins. Formerly a forged high-tensile shaft without hardening was used.

Steel shells lined with copper-lead material replace the white-metal main and big-end bearings used in the earlier models, and the connecting-rod caps are secured by bolts, nuts and lock plates. The top piston rings of the modified unit are chromium-finished on the outer surface 'to improve their life and to prevent corrosion.

Breathing arrangements have been redesigned, the crankcase ventilation being controlled by a suction pipe, incorporating an A.C. Donaldson valve between the push-rod cover and induction manifold. An oilbath cleaner is fitted to the top of the rocker cover to filter air entering the crankcase; • the carburetter air cleaner is also of oil-bath pattern.

Other modifications to the latest unit include a detachable-element by-pass_ oil filter and white-metal-faced half-thrust washers to control the crankshaft end-movement. A large-bore induction manifold and a Zenith 42 VIS-3 carburetter are now provided for the model "0" engines. They increase the net power from c4 68.5 b.h.p. at 2,800 r.p.m., which was delivered by the original unit, to 80 b.h.p. at 3,100 r.p.m. Torque has been raised from 164 lb.-ft. to 166 lb.-ft. at 1,000 r.p.m.

These net power figures are for the complete engine with standard accessories, including dynamo, fan, silencer and tail pipe, and with normal ignition timing.

Alterations made to increase the life of the engine cannot be assessed during a road test, but the maker provided an OL13D model, so that I could verify the improved performance. Apart from the engine, the chassis was the standard longwheelbase 5-tonner of the same class as the model on which I reported on December 12, 1947. To obtain a direct comparison, I tested the latest version over the same course as covered in the earlier trial.

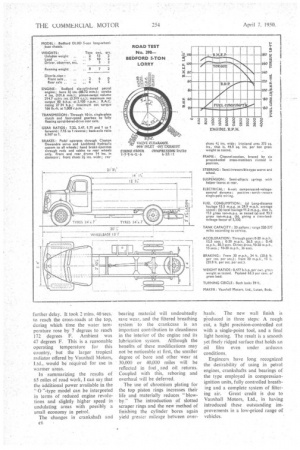

A check on the running weight showed the Bedford was operating at 8 tons 7i cwt., whereas the gross load in the previous test was 8 tons 31 cwt. Gear ratios and tyre sizes were the same, and the unladen weight was unchanged.

The hill leading up to the main Luton-St. Albans road again caused m a rk ed detonation when climbing in third gear and, as before, second gear was engaged to prevent harm to the engine. The lorry was well run-in, having covered over 8,000 miles since leaving the assembly line.

The acceleration trials were made under ideal conditions on the BarnetHitchin road, the atmosphere being so calm that smoke was rising vertically from factory chimneys Using the same gear-changing technique as before, employing all ratios and changing gear at 3 rn.p.h., 13 m.p.h. and 24 m.p.h., the acceleration time from rest to 30 m.p.h. was 30 secs., or 1.1 secs. faster than with the lower-powered engine. When the three intermediate gears were used, the time was reduced to 26.5 secs. Engaging direct drive at 34 m.p.h., we reached 40 m.p.h. in 50.3 secs.

Because of the relatively low increase in torque-2 lb.-ft. at 1,000 r.p.m.—the acceleration from 10-30 m.p.h. in direct drive was almost the same as before. The time required to reach 20 m.p.h. was reduced by 0.2 sec., but 0.8 sec. longer was needed to attain 30 m.p.h No marked improvement in performance was observed on these trials, but greater advantage was shown when climbing normal inclines on the main roads, where top gear could be used for longer periods, thus reducing the number of engine revolutions per mile.

After the acceleration trials, 1 made a number of emergency brake applications to confirm the theoretical 100 per cent. stopping .distance obtained before. On this occasion the retardation was almost equally abrupt, the stopping distance from 30 m.p.h. being 36 ft. with all wheels kicking On a good, dry, concrete surface. •

• An initial consumption trial was spoiled by a stop at the foot of Welwyn Hill, after. which we had to climb in tow ratio, the fuel return being 12.1 m.p.g. A one-stop-permile run was made on the return to the original starting point, and this yielded a result of 11.2 m.p.g., a decidedly economical return for the equivalent of local operation.

Traffic conditions during the nonstop consumption trial were easy and a steady 30-33 m.p.h. was maintamed on all level stretches. 1 was driving at 33 m.p.h. at the approach to Welwyn Hill, and the Bedford continued to pull steadily in top gear for a good distance. The engine timing appeared to be well advanced, and I was forced to change to an indirect ratio at 26 m.p.h., when heavy detonation set in.

There was ample engine power available in this gear, and I released the accelerator pedal to part throttle opening, which was sufficient to maintain a steady speed without over-revving. Top gear was employed for the remainder of the eight-mile trial, which ended at Stevenage. 1 note, according to the 1947 report, that third gear was used for the final incline.

The average speed worked out to 29.9 m.p.h., or 0.8 m.p.h. faster than with the •lower-powered engine, and the fuel return of 13.5 m.p.g compares reasonably with that yielded by the earlier test. A minor adjustment to the ignition timing of the test vehicle would have enabled direct drive to be used more extensively on Wel w yn Hill, with corresponding economy in fuel Detonation began early during the top-gear acceleration trials and was more noticeable between 10-15 m.p.h. than at other times.

Pleasant Handling

While driving to Oftley 1E14'1 found time to note the easy handling and light steering which are speciali

ties of the Bedford design The vehicle has a comfortable cruising speed of 38-441 m.p.h., and a maximum speed approaching 50 m.p.h.

Shock absorbers may be fitted to customers' requirements, but I could find no fault in the suspension system for operation in this country In my experience of -Bedford chassis overseas, I have always considered them among the best sprung of their class, when travelling over rough roads, even without shock absorbers fitted.

The radiator temperature was recorded at the foot of 011ie}, Hill and the incline was tackled without

further delay. It took 2 mins. 46secs. to reach the cross-roads at the top, during which time the water temperature rose by 7 degrees to reach 172 degrees F. Ambient was 47 degrees F. This is a reasonable operating temperature for this country, but the larger tropical radiator offered by Vauxhall Motors, Ltd., would be required for use in warmer areas.

In summarizing the results of 65 miles of road work, I can say that the additional power available in the "0 "-type model can be interpreted in terms of reduced engine revolutions and slightly higher speed in undulating areas with possibly a small economy in petrol.

The changes in crankshaft and c6 bearing material will undoubtedly save wear, and the filtered breathing system to the crankcase is an important contribution to cleanliness in the interior of the engine and its lubrication system. Although the benefits of these modifications may not be noticeable at first, the smaller degree of bore and other wear at 30,000 or 40,000 miles will be reflected in fuel and oil returns. Coupled with this, reboring and overhaul will be deferred.

The use of chromium plating for the top piston rings increases their life and materially reduces "blowby." The introduction of slotted scraper rings and the new method of finishing the cylinder bores again yield greater mileage between over

hauls. The new wall finish is produced in three steps: A rough cut, a light precision-controlled cut with a single-point tool, and a final light honing. The result is a smooth yet finely ridged surface that holds an oil film even under arduous conditions.

Engineers have long recognized the desirability of using in petrol engines, crankshafts and bearings of the type employed in compressionignition units, fully controlled breathing and a complete system of filtering air. Great credit is due to Vauxhall Motors, Ltd., in having introduced these outstanding improvements in a low-priced range of vehicles.