THE RALLS SUSPENSION.

Page 8

Page 9

If you've noticed an error in this article please click here to report it so we can fix it.

A Springing System that is as Good for the Roads as for the Vehicle.

N0 part of the commercial-motor vehicle appears to have altered so little as the springing. Yet, it ia equally true that in no part is there such need for improvement. The subject of vehicle springing as a whole is a wide and extremely difficult one.

The problem of springing is generally considered from the point of view of the vehicle, and the absorption within its mechanism, in which we include the springs, of shocks due to impact between the wheels and uneven portions of the road surface. The object, of course, is to diminish or eliminate these shocks before they reach the body of the vehicle or its occupants, whether the latter be goods or passengers.

The other side of the question, namely, the effect on the road surfaces of the frequent passage over them of badly-sprung and heavy vehicles, although not entirely lost to view' does not so frequently come up for consideration, at least, not on the part of manufacturers or users of those vehicles. -Yet, as wa-s, pointed out by Mr. H. T. Chapman, in an article which appeared in our issue of February 6th, entitled "Road Requirements for Modern Traffic," this is an aspect. which must be kept, continuously in mind if we are ever to feel the benefit of permanently good roads. There must, in other words, be reciprocal and mutual

action on the part of road maker and road user if a state of affairs permanent and satisfactory to both is to be achieved. Only by such combined action will the road maker feel that some useful result is likely to accrue from his efforts, and the road users experionce that comfort to passengers and safety in transit of delicate goods, which is essential.

It cannot be denied that the solid-tyred vehicle is tt greater offender in this respect than its pneumatictarred prototype. The pneumatic tyre automatically' absorbs a considerable percentage of minor shocks which, in the ease of solids, are largely transmitted to the axle and thence to the springs. They do more,however. It will be realized, after very little. consideration of the design of the normal type of semi. elliptic spring which is almost universally employed for motor vehicles, that it can satisfactorily absorb only those shocks which take effect solely in a vertical direction. Horizontal blows, and the horizontal components of forces ether than vertical must otherwise be accounted for. The pneumatic tyre is capable of performing some of this service; the solid tyre on a vehicle running at speeds of over five or six miles an hour is not sufficiently rapid in its action to do so. The consequence is that the solid-tyred vehicle with normal springing receives, almost uncushioned, all

B28 the horizontal blows as well as the horizontal component of every shock which the wheels suffer.

The solution' obviously, is to provide some springing element which -will counter these shocks, and relieve the chassis and its mechanism from this unnecessary and harmful hammering. Occasional and tentative attempts to_ provide some such absorbent medium have been made, and of them the most practical and successful is, undoubtedly,, thatnne patented by Mr. G. E. D. Rails, M.I.Mech.E., M.I.A.E„ the managingldirector of the Birmingham and Midland Counties' Transport Co., Ltd. His system of suspension was incorporated in a reton petrol .chassis, the.first model of which appeared during the war, and was described by Us in our issue of _Sept 13th, 1917. The springing— at least, so far as the rear portion is concerned—was fully described and illustrated in that article. It may be recalled that the single torque and twin radius rods were spherically jointed at their front ends ; the former to a single-ended lever on a hollow shaft, free to revolve, thus removing all longitudinal constraint from the torque rod; the latter to double-ended levers, keyed at about their centres to a common transverse shaft. The upper ends of these levers were forked and engaged horizontal plungers, Which were held between a pair of substantial helical springs. In this manner was provision made for the horizontal elasticity. This device worked well and efficiently, as we discovered. at the time, and as we' have since on several occasions verified. When we made our previous examination, this de-.. vice had not been applied to the front springs, although, and in time for a brief reference in our article, a preliminary design for its application was completed. After a little modification, the front springing of the chassis which we described was constructed on similar lines to the rear, and the actual method of carrying this into effect may be gathered by reference to the illustrations which accompany this article. Its external appearance may be judged from the photographs, and a sectional drawing illustrates the internal features of the design. These are so clear that hardly any verbal embellishment is needed. It will be gathered that, in addition to making provision for absorption of horizontal shocks, which provision is very similar in principle to that adopted for the rear axle, there is also means for accommodating that extra load which front springs are frequently called upon to bear when the axle almost bodily drops into the hollow of a " wave " in the road. It will be noticed that this supplementary cushioning is partly

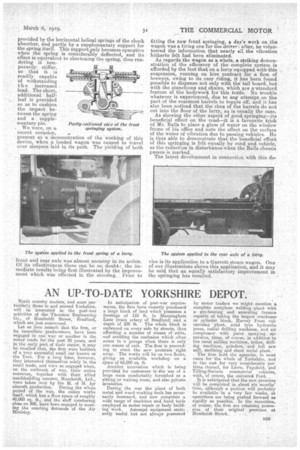

provided by the horizontal helical Springs of the shock absorber, and partly by a supplementary support for the spring itself. This support.sanly becomes operative when the spring is consideralily deflected, and its effect is equivalent to shortening the spring, thus rendering it temporarily stiffer, so that it is readily capable of withstanding the increased load. The short, additional halfleaf is provided so as to cushion the impact between the spring and a supple mentary pin. Partly-sectioned view of the front , We were, on a. springing system.

recent occasion, present at a demonstration of the working of this device, when a loaded wagon was caused to travel over sleepers laid in its path. The yielding of both fitting the new front springing, a day's work on the wagon was a tiring one for the driver: after, he volunteered the information that nearly all the vibration hitherto felt had been eliminated.

As regards the wagon as a whole, a striking demonstration of the efficiency of the complete system is afforded by the fact that on a lorry equipped with this suspension, running on hire contract for a firm of brewers, owing to its easy riding, it has been found possible to dispense not only with the tail board, but with the stanchions and chains, which are a-standard feature of the bodywork for this trade. No trouble whatever is experienced, due to anv attempt on the part of the rearmost barrels to topple off, and it has also been noticed that the rims of the barrels do not cut into the floor of the lorry, as is usually the case. As showing the other aspect of good sprniging—its beneficial effect on •the road—it is a favourite trick of Mr. Halls to place a glass of water on the window frame of his office and note the effect on the surface of the water of vibration due to passing vehicles. Ho is thus able to demonstrate that the -beneficial effect of this springing is felt equally by road and vehicle,

i as the reduction n disturbance when the Halls chassis passes. is marked. The latest development in connection with this de