by Johnny Johnson

Page 67

Page 68

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

Beer distribution in bulk is affected by both weather and seasonal demand. Only a total distribution concept can satisfy the demands of Truman's customers

THE science of physical distribution management (PDM) might be considered to be a fairly recent innovation and though many organisations pay lip service to its efficiency, it is more honoured in the breach than in the observance.

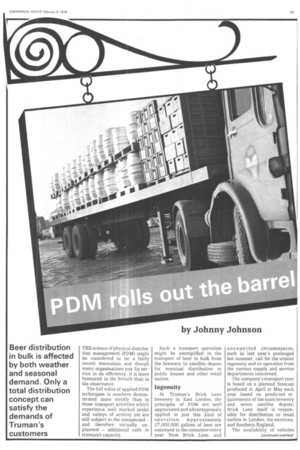

The full value of applied PDM techniques is nowhere demonstrated more vividly than in those transport activities which experience well marked peaks and valleys of activity yet are still subject to the unexpected — and therefore virtually unplanned — additional calls in transport capacity. Such a transport operation might be exemplified in the transport of beer in bulk from the brewery to satellite depots for eventual distribution to public houses and other retail outlets

Ingenuity

At Truman's Brick Lane brewery in East London, the principles of PDM are well appreciated and advantageously applied in just this kind of operation. Approximately 27,000,000 gallons of beer are conveyed to the consumer every year from Brick Lane, and unexpected circumstances, such as last year's prolonged hot summer, call for the utmost ingenuity and co-operation from the various supply and service departments concerned.

The company's transport year is based on a planned forecast produced in April or May each year based on predicted requirements of the main brewery and seven satellite depots; Brick Lane itself is responsible for distribution to retail outlets in London, the environs, and Southern England.

The availability of vehicles for satisfying the predicted demands is carefully charted having regard to possible augmented deliveries in anticipation of peak periods before the peaks actually begin. The purchase or replacement of vehicles is contingent upon the demands of the plan, converted to a tonnage basis and related to vehicle capacity available.

The bulk delivery fleet at Brick Lane comprises 15 AEC Mandator tractive units matched with 32 trailers. Of these, 15 are tank trailers of about 4,500 gallon capacity. To make things more difficult for the layman the tank capacity is quoted in "barrels". Each tank is calculated at 120 barrels capacity; a barrel is 36 gallons, so the tank is calculated to hold 4,320 gallons. The other 17 trailers are flats for transporting beer packaged in barrels or bottles.

Based at the Swansea depot are two Scammell tractors which share a night trunk between Swansea and London with Brick Lane-based tractive units.

Staging Because the company prefers its drivers to be allocated their own tractive unit as far as possible, this trunk is accomplished by drivers from the respective depots dropping trailers at a staging point at Leigh Delamere service station on M4, crossing, by an adjacent bridge and recoupling tractive units to each other's trailer for return to own depot. The westbound trailer is loaded with bulk beer and the eastbound trailer usually carries returned empties.

Of course, the tractive units are available for work during the day with other drivers after returning to base.

As well as Swansea, depots at Edmonton, Norwich, Gravesend, Thanet, Swindon and Colchester are kept supplied from Brick Lane. The last depot has also a bottling plant so that bulk beer in tankers is a significant part of the transport to Colchester.

Some of the raw material for the brewing process is brought in bulk to Brick Lane by the company's own transport. Prominent here are two eightwheel Mammoth Major tippers based at Sudbury which carry malt from the East Anglia to the Brick Lane brewery averaging two trips a day each.

The bulk delivery fleet is augmented by two Buffalo tractors and three tank trailers on contract hire from Bulwark Ltd. This contract also secures the hire of further units if demand requires further quick increase in fleet capacity.

Apart from spare AEC tractive units for contingencies, the only other bulk fleet units are three Ford D1716 tractive units which are matched with small tank trailers. These are used for supplying the requirements of other manufacturers to small local bottlers. The tanks bear a detachable nameboard bearing the name of the particular brew being transported.

The overall responsibility for bulk beer movement and distribution is borne by Mr Ken Worth, the distribution director. He receives a stock and depot order statement each morning so that production of different kinds of bulk and packaged beer can be adjusted on a daily basis.

Liaison

Responsible for warehouse management, bulk deliveries, stock control and planning and programming of movements, Mr Geoff Upsdell maintains liaison with the production department and makes provision for the logisitics.

Fleet manager Mr D. J. Arrow is the man who makes sure of the availability of the vehicles which Geoff Upsdell requires, but has also under his care the company cars and mechanical handling requirement as well as the small vans required by a small section which looks after the beer service and installation of public house equipment.

The depot fleets of nearly 100 7-ton distribution vehicles also come under the jurisdiction of Derek Arrow and are mainly maintained at two garages in London and Colchester.

A careful eye is kept on transport costs though the costing of individual vehicles is not considered desirable involving a great deal of possibly unnecessary clerical effort. Batch costing based on vehicle makes and types provides a realistic yardstick on which to base vehicle costing forecast.

It is on these forecasts that the service department of the fleet manager bases a charge to the using department for the use of the vehicle. This includes maintenance and repair, tyres, lubrication, fuel, licensing and insurance. The driver's wages are not included this being considered a separate cost incurred by the warehousing department. However, the warehousing department obviously makes a critical continuous assessment of the charge for vehicle use being made apart from the monitoring of vehicle performance made by the fleet managers. Obviously, if the cost of the vehicles is exceeding the average being made the fleet manager has no wish for this to be debited against his department and he will take quick action to find out the cause.

It is only in circumstances such as these that an investigation will be made into individual vehicle costs.

The source of the variation between cost and charge is easily and quickly traced to the particular batch of vehicles concerned. It remains only to isolate the particular vehicle causing the variation — not too difficult a task — and to evaluate the acceptability of the greater than budgeted cost.

Replacement

It might be that quick vehicle replacement might be called for or a decision to accept the extra cost in view of the repair or component replacement undertaken. This is typical of the interplay between the various functions of raw material supply, production, warehousing and distribution and fleet management which prevails in a properly integrated PDM project.

There is no doubt that physical distribution management confirming or manipulating the various kinds of beer production in relation to depot demands and vehicle availability and capacity — sometimes at very short notice — contributes to the efficient supply of Truman's beer at point of sale.

During a summer such as that experienced last year when demand for liquid refreshment from Britain's national beverage soared, only PDM was considered equal to the task at Brick Lane.