Road Test of Mo Monner

Page 54

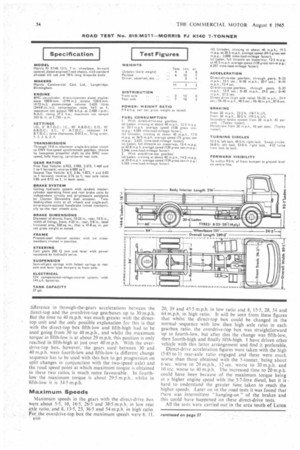

Page 55

Page 56

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

NOW that five-speed gearboxes with alternative sets of ratios and two-speed or single-speed rear axles

• are commonly options on medium-payload vehicles, operators must often be in a quandary as to what to specify. Having just completed road tests of a Morris Fi 7-tonner, first with the standard direct-drive-top gearbox and later with the optional overdrive-top unit, I have no doubt that for general haulage over varied types of routes the latter is by far the better proposition with a two-speed axle, as fitted in the test vehicle.

1 can see little point in sticking to the standard box with the two-speed axle, as the 10 forward ratios given with the overdrive unit and this axle will be more than adequate for the hilliest of routes, whilst the advantage in fuel economy provided by the overdrive on steady running will be most beneficial There was almost a 17 per cent improvement with overdrive on the fuel-consumption test over a lightly undulating route. Rather surprisingly there was almost the same fuel consumption on high-speed tests with the two boxes, but there was a useful increase in average speed with the overdrive—and if the same average speed had been the case, fuel consumption naturally would have been better than when the direct-drive box was fitted.

There may be types of operation where the specification of the direct-drive gearbox would give advantages, but in my opinion these would be only where the exact nature of the roads to be travelled was known. This would allow the right selection of axle ratio—either singleor two-speedto be made, but then the vehicle could have difficulty if ever the area of operation was changed. For versatility, I do not think the overdrive with two-speed axle can be bettered and is certainly well worth the extra £10 and £60 respectively that the fitting of these two options incurs.

The results of the test revealed many points in the 7-tonner's favour, particularly in respect of fuel consumption. General performance on the road was well up to standard and the acceleration figures obtained were reasonably good, as were the results of the brake tests. With regard to the FJ cab—comfort, access and so on—the remarks I made in the test report of the 5-tonner (The Commercial Motor, March 12, 1965) apply; the design is excellent and the facilities provided about as good as one can get in any British cab. Handling characteristics were also found to be very good; the power steering of the test vehicle (this is an option on the model) gave a good " feet " without any of the sponginess and vagueness that often takes some getting used to when first taking over a vehicle with this feature.

Appearance

In outward appearance the ET K140 7-tonner is almost identical with the 5-tonner, the only difference being in the size of tyres-8.25-20 • against 7.50-20. Mechanically the main difference between the two models is that the BMC 5-7-litre diesel is used in the 7-tormer against the 5.I-1itre

in the 5-tonner. These two engines give maximum outputs of 90 and 105 b.h.p. at 2,400 r.p.m. respeeLy and maximum net torques of 224 lb. ft. at 1,500 n. and 250 lb. ft. at 1,750 r.p.m. respectively. Like the nner, the 5-tonner has the ENV five-speed, direct-drivegearbox as standard and the overdrive unit as an on. Also identical are the steering systems and front rear axles and generally the same alternatives are red, although in the case of the rear axle ratios the dard fitting varies. Spring ratings and brake dimens are increased for the 7-loaner to cater for the higher ;hit and in the case of brakes the 7-tonner has a total .ional area of 520 sq. in. compared with 415 sq. in. on 5-tonner.

his brake lining area applies to the three longest wheel; models in the FJ K140 range—the 12 ft. 7 in., 14 ft. . and 16 ft. 9 in. On the shortest (9 ft. 3 in.) wheelbase lel—which is intended for tipper applications—there is [nerease in the width of the rear linings which brings frictional area to 573 sq. in. This short-wheelbase nner actually has a number of special features, includa heavy duty, single-speed axle as standard and a heavy / unit with two-speed Eaton head as the alternative.

aking System

:andard throughout the H range, which includes an nner and an 18-ton g.t.w. tractive unit as well as the ad 7-tanners, is a dual air-hydraulic braking system with :pendent hydraulic circuits to front and rear axles and 3ressure assistance by a dual actuator fed by separate 3ysterns. If one of the air systems fails partial braking pplied to all wheels, and to give improved handbrake iency air-pressure assistance is provided in the form of actuating chamber connected to a relay lever in the hanical linkage at the rear brakes,

For the road tests. the FJ was loaded with gravel weighing 6 tons 15.25 cwt. and with three people in the cab the gross weight was brought to 11 tons 35 cwt. ThiS compares with the figure of 11 tons quoted by BMC as the maximum permissible gross weight, so this represented a slight overload. But there is no certainty that this weight was maintained throughout the tests. The gross figure was obtained at the start of the tests, but these took place during a week of frequent heavy rain and unfortunately there was no protective covering over the load, Running at this gross weight gives the power/weight ratio of 9,4 b.h.p, per ton, a figure only marginally lower than that at which the FJ 5-tonner was tested.

Because of this it was expected that the performance of the 7-tonner would be little different from that of the 5-tonner, but whilst this was so as an overall impression in general running about, it did not turn out to be true on the acceleration tests. This was no doubt because the engine speed at which maximum torque is obtained on the 5-7-litre engine is different from that of the 5-1-litre unit. difference in through-the-gears accelerations between the direct-top and the overdrive-top gearboxes up to 30 m.p.h. But the time to 40 m.p.h. was much greater with the directtop unit and the only possible explanation for this is that with the direct-top box fifth-low and fifth-high had to be used going from 30 to 40 m.p.h., and whilst the maximum torque in fifth-low is at about 29 m.p.h. this position is only reached in fifth-high at just over 40 m.p.h. With the overdrive-top box. however, the gears used between 30 and 40 m.p.h. were fourth-low and fifth-low (a different change sequence has to be used with this box to get progression on split changes in conjunction with the two-speed axle) and the road speed point at which maximum torque is obtained in these two ratios is much more favourable. In fourthlow the maximum torque is about 29.5 m.p.h., whilst in fifth-low it is 34-5 m.p.h.

Maximum Speeds

Maximum speeds in the gears with the direct-drive box were about 5-5, 10, 16.5, 26.5 and 38-5 m.p.h. in low rear axle ratio, and 8, 13-5, 23, 36-5 and 54 m.p.h. in high ratio. For the overdrive-top box the maximum speeds were 6. 11, 20, 39 and 45-5 m.p.h, in low ratio and 8, 15.5, 28, 54 and 64 m.p.h. in high ratio. It will be seen from these figures that whilst the direct-top box could be changed in the normal sequence with low then high axle ratio in each gearbox ratio. the overdrive-top box was straightforward up to fourth-low, but after this the change was fifth-Tow, then fourth-high and finally fifth-high. I have driven other vehicle with this latter arrangement and find it preferable. Direct-drive acceleration figures were taken with the high (5.85 to 1) rear-axle ratio engaged and these were much worse than those obtained with the 5-tonner, being about 6 sec. worse to 20 m.p.h., 12 sec. worse to 30 m.p.h. and 10 sec. worse to 40 m.p.h. The increased time to 20 m.p.h. could have been because of the maximum torque being at a higher engine speed with the 5.7-litre diesel, but it is • hard to understand the greater time, taken to reach the hieher speeds. Later on in the road tests it was found that there was intermittent "hanging-on " of the brakes and this could have happened on these direct-drive tests.

All the tests were carried out in the area south of Luton

it was only when the vehicle was being driven from mingham for the unladen fuel consumption runs on the

I day that the fault with the brakes was noticed; there been no impression of the brake shoes not releasing quately on the laden runs. It is, in my opinion, unlikely this was the case in the fuel-consumption runs when y-laden, as the figures obtained were quite consistent iughout the four tests made.

: must be remembered, when comparing the figures, that normal-speed tests were taken for runs cruising at und 40 m.p.h. No tests with a 30 m.p.h. maximum were -ied out, but from past experience it can be said that ping to this maximum, consumption figures about 15 per t better than those obtained when running at up to n.p.h._ would result. This would give about 14 m.p.g. the direct-drive-top gearbox and a little more than n.p.g. with the overdrive-top unit. Taken all round the -consumption test results show the FJ 7-tonner to be economical vehicle, aking Performance

raking performance of the test vehicle was reasonably d and the figures obtained on the maximum-pressure )s from both 20 and 30 m.p.h. represent actual efficienof mound 60 per cent, which means that the vehicle will form to the requirements that are likely to be introed for all vehicles before long. This is so even if the iistry of Transport goes the tull way in requiring the re of 60 per cent to be obtained by stopping distance.

• Tapley meter reading is acceptable the 7-tonner will veil within the limits, as the readings obtained on these ; were 78 per cent from 30 m.p.h. and 85 per cent from ri.p.h. One side of the air-pressure assistance was disnected to check the effectiveness of the secondary-brake ure of the FJ system and this gave a Tapley meter ling of 42 per cent, very close to the figure ot 43 per obtained using the air-assisted handbrake.

in all the maximum-pressure stops there was some .ing of the rear wheels—at both on the stops from ri.p.h. but only the offside one on the stops from 30 .h. There was only the very slightest of marks from front tyres, so there is scope for improving the stopping owes by increasing the effort or lining area at the front. ; was also the case with the 5-tonner tested. but I found 7-tonner much more stable on the stops.

II Climbs ill-climbing performance tests were carried out on in Hill, near Whipsnade Zoo. This 0.75-mile hill an average gradient of 1 in 10-5, with the maximum 6.5. With the direct-drive-top gearbox, on the first day he tests, the 7-tonner completed a maximum-power nt in 4 min. 19 sec. The lowest gear needed was second, in which 1 mm. 30 sec. was spent and the minimum d was 7 m.p.h. Ambient temperature at the time of test was 17-5°C (64°F) and on the climb there was no -eciable increase in the gauge reading of engine coolant Derature from the initial 75°C (168°F); there was no ibility of taking direct coolant-temperature readings as F.1 system incorporates a separate header tank.

run down the hill was made to assess the brake fade, t of the descent being made in neutral with the brakes ied to keep the speed to 20 m.p.h. Near the bottom, re the gradient is less, top gear (low axle ratio) was .ged and with full throttle applied the brakes kept on estrict the speed to the same figure. A maximumsure brake stop from 20 mp.h. at the end of the ent, which had taken 2 min. 28 sec. with 31 sec. spent ear, produced a Tapley meter reading of 85 per cent. his was the same as the best figure obtained on the er cold-drum runs it can safely be said that the FJ mer should give no problem with brake fade.

returr to the steepest section of the hill was made following the fade test to carry out stop and restart tests. Here, trouble occurred. Following the usual practice, an attempt to restart was made in the lowest gear used on the hill-climb test--second low. In the course of this, with the. engine revving and the clutch being allowed in gradually, there was a sharp bang from the rear end and we had lost the low rear-axle ratio. The high ratio was still operative and a comfortable restart in first-high was made to the accompaniment of slight protests from the rear axle. As only the reverse restart test remained to be done with the direct-top box, it was decided to attempt this in spite of the obvious damage. Then the axle repairs could be made at the same time as the gearbox was changed for the tests with the overdrive unit. Fortunately, the axle held up and an easy restart in reverse high was made when facing down the slope. But this did not improve the health of the axle as the noise got worse and help had to be called. When facing up and facing down the hill, the handbrake had held the vehicle with ease.

To be fair to BMC it should be said that no driver would have attempted to start on the 1-in-6.5 gradient in second gear, even with the lower axle ratio, and if we had tried only first-high there would have been no failure. In my opinion a contributing factor was the uncertain feel of the clutch: on the 7-tonner there is hydraulic air assistance.

It was thought that the ratio change was damaged but on stripping down by BMC the failure was found to be caused by a fractured differential bearing cap and that the origin was faulty fitting of the bearing locking collar. I was told that this type of failure had been experienced only once in the life of the particular axle design—BRS have been using the design on 17-ton g.t.w. tractive units for four years and have had no similar trouble. The one failure was on a prototype a short time ago, and following this modifications were put in hand to overcome the possibility of incorrect fitting. These are now said to be fully operating. The test vehicle was built before the alterations were effective and somehow the necessary changes had not been made to its differential.

A repeat of the hill performance tests was made when the overdrive-top gearbox was fitted and here the climb was completed in 4 min. 28 sec. with first-high. the lowest ratio, used for I min. 27 sec., and the minimum speed was 6 m.p.h. Again there was no appreciable rise in engine cooling temperature on the ascent. Stop-and-restart tests showed that the FJ with overdrive box was capable of starting off also in first-high when facing up the slope and in reverse-high when facing down it, although in the latter case it was not possible to get up any speed. A restart up the hill in reverse-low was perfect.

The differential trouble was not the only difficulty experienced on the test; there was also the brake binding, which turned out to be caused by a bit of dirt in the master cylinder, and later in the test the speedometer cable broke (this could happen to anybody). To cap it all, when topping up the test tank for the empty fuel consumption runs on the final day it was found that instead of derv, 5 gal. of liquid soap had been supplied—and some put in the test tank before it was realized that it was not fuel!

In spite of all these tribulations I must say I enjoyed testing the FJ 7-tonner it is a very pleasant vehicle to drive, with easy controls and a most comfortable cab and seating. I can add little to the favourable comments I made in the test report of the 5-tonner and what I have already said earlier in this report. Although a bit difficult to get fine control, 1 found the clutch pedal commendably light, as was the brake pedal. On the other hand, the accelerater pedal was set rather high and a little stiff in operation, which, coupled with the temperamental clutch and a two-low idling-speed setting on the engine during the first day's teSts, caused frequent stalling of the power unit when starting off. This was better on the later tests when the engine speed had been set higher.

As tested the FJ K140 7-tonner costs £1,695, this figure including the drop-side body. Optional extras fitted, with prices, are: overdrive gearbox, £10; power-assisted steering. £50; and BMC two-speed axle, £60.