Power Recovery

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

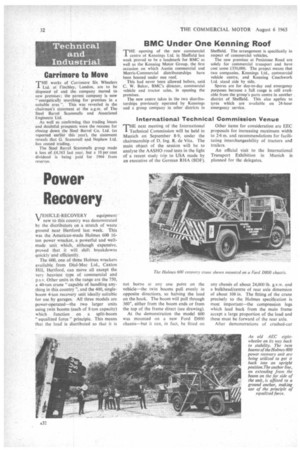

VEHICLE-RECOVERY equipment V new to this country was demonstrated by the distributors on a stretch of waste ground near Hertford last week. This was the American-made Holmes 600 16ton power wrecker, a powerful and wellmade unit which, although expensive, proved that it will shift breakdowns quickly and efficiently.

The 600, one of three Holmes wreckers available from Dial-Mec Ltd., Caxton Hill, Hertford, can move all except the very heaviest type of commercial and p.s.v. Other units in the range are the 750, a 40-ton crane "capable of handling anything in this country ", and the 400, singleboom 4-ton recovery unit ideally suitable for use by garages. All three models are power-operated—the two larger units using twin booms (each of 8-ton capacity) which function on a split-boom "equalized force" principle. This means that the load is distributed so that it is not borne at any one point on the vehicle—the twin booms pull evenly in opposite directions, so halving the toad on the hook. The boom will pull through 3600, either from the boom ends or from the top of the frame direct (see drawing).

At the demonstration the model 600 was mounted on a new Ford 0800 chassis—but it can, in fact, be fitted on

any chassis of about 24,000 lb. g.v.w. and a bulkhead/centre of rear axle dimension of about 108 in. The fitting of the crane precisely to the Holmes specification is most important—the compression legs which lead back from the main frame accept a large proportion of the load and these must be forward of the rear axle.

After demonstrations of crashed-car

very, attention was turned to an old— very much abused—AEC eighteler. This was shortly—and certainly for the first time—pulled on to its . Then the "equalized Force" was demonstrated. A 90° side-pull given, making use of an outboard leg give positive ground contact) and a tnd anchor on the opposite side of the Ater to the AEC. Very deliberately

veteran was raised to its feet ". n it had its front hauled up and was :c1 away. The whole operation took store than 20 nainutes, most of which spent by two ultra-efficient operators Jerry connecting towing hooks to the

front axles, so that when lifted the front end of the AEC would not be fooled in any way, by metalwork on the sling. Demonstrably a very efficient recovery!

Main Features

Interesting features of the Holmes 600 are (a) the nylon-bushed, heavy-duty controls—these are mounted at the rear end of the unit and can be operated from either side of it; (b) the outboard legs (mounted on large swivel bases) which can be used in the vertical position or at any angle up to 30°, and (c) the rapidreverse, twin-worm power units, which give independent single-lever control of each drum.

The strong, all-welded body is 92 in wide. It has large side compartments forward, side-mounted hold-down brackets, a double-flanged tailgate, and stainless-steel recessed tail lights.

Prices of these cranes, which includes mounting on a vehicle if required, are as Follows: Model 600, £1,320; Model 750. £1,950; Model 400, £445. These prices' do not include cost or fitting of the power take-off, which will vary according to the vehicle selected. The body demonstrated can be fitted at the same time as the crane—again price depends on vehicle used. but will be approximately 000.