Unusual Outfit for Sub-surface Exploration

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

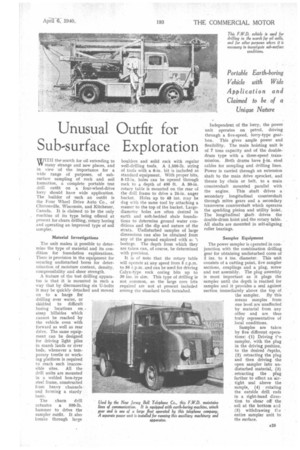

Portable Earth-boring Vehicle with Wide Application and Claimed to be of a Unique Nature

the search for oil extending to VV many strange and new places, and in view of the importance for a wide range of purposes, of subsurface sampling of rock and soil formation, a complete portable test drill outfit on a four-wheel-drive lorry should have wide application. The builder of such an outfit is the Four Wheel Drive Auto Co., of Clintonville, Wisconsin, and Kitchener, Canada. It is claimed to be the only machine of its type being offered at present for churn drilling, rotary boring and operating an improved type of soil sampler.

Material Investigations The unit makes it possible to determine the type of material and its con dition for foundation explorations. There is provision in the equipment for securing undisturbed bores for determination of moisture content, density, compressibility and sheer strength.

A feature of the tq:%t drilling apparatus is that it is mounted in such a way that by disconnecting six U-bolts it may be quickly detached and moved on to a barge for drilling over water, or skidded to difficult boring locations on steep hillsides which cannot be reached by the vehicle even with forward as well as rear drive. The same equipment can be designed for driving light piles in marsh lands or river beds, whenever a temporary trestle or working platform is required to reach such inaccessible sites. All the drill units are mounted in a welded box-type steel frame, constructed from heavy channels and forming a sturdy basis.

The churn drill actuates a 500-lb, hammer to drive the sampler outfit. It also breaks through large boulders and solid rock with regular well-drilling tools. A .1,500-lb. string of tools with a 6-in, bit is included as standard equipment. With proper bits, 8-12-in, holes can he opened through rock to a depth of 400 ft. A 30-in. rotary table is mounted on the rear of the drill frame to drive a 24-in, auger bucket. Holes up to 48 ins. may be dug with the same tool by attaching a reamer to the top of the bucket. Largediameter holes are often desired in earth and soft-bedded shale foundations to determine ground water conditions and the dip and nature of the strata. Undisturbed samples of large dimensions can also he obtained from any of the ground explored with at. borings. The depth from which they are taken can, of course, be determined with precision.

It is of note that the rotary table will operate at any speed from 5 r.p.m. to 50 r.p.m. and can be used for driving Calyx-type rock coring bits up to 30 ins. In size. This type of drilling is not common, so the large core bits required are not at present included among the standard tools furnished. Independent of the lorry, the power unit operates on petrol, driving through a five-speed, lorry-type gearbox. This gives ample power and flexibility. The main hoisting unit is of 7 tons capacity and of the doubledrum type with a three-speed transmission. Both drums have I-in. steel cables for sampling and drilling lines. Power is carried through an extension shaft to the main drive sprocket, and thence by chain or belt, to a main countershaft mounted parallel with the engine. This shaft drives a secondary longitudinal countershaft through mitre gears and a secondary transverse countershaft which operates the spudding pinion and utility hoist. The longitudinal shaft drives the double-drum hoist and the rotary table. All shafts are mounted in self-aligning roller bearings.

Sampler Equipment The power sampler is operated in conjunction with the combination drilling gear for obtaining undisturbed cores of 2 ins. to 4 ins. diameter. This unit consists of a cutting point, five sampler sections, couplings and a plug, screw and nut assembly. The plug assembly is most important as it plugs the sampler until the depth is reached for samples and it provides a seal against suction immediately above the top of the sampler. By this means samples from one level are unaffected by material from any other and are thus truly representative of local conditions.

Samples are taken by five different operations: (I) Driving t'-e sampler, with the plug in the driving position, to the desired depths, (2) retracting the plug and then driving the open sampler into undisturbed material, (3) retracting the plug farther to effect an airtight seal above the sample, (4) rotating the outside drill rods in a right-hand direction to shear off the soil at the bottom ad (5) withdrawing tile entire sampler unit to the surface.