• Safer Braking with New Coupling

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

Remarkable Results with New Brockhouse Units for "Attics"

BASED on well-tried principles; a new coupling gear for articulated units of up to 11 tons payload has been introduced by J. Brockhouse and Co., Ltd., West Bromwich. It is known as the Mk. lV Interchangeable and can be used with icammell M.H., Taskers DS and Hands G-type semi-trailers, in addition to Mark Ill Brockhouse units.

A new braking system eliminates delay Ind gives smoother retardation, thereby -educing the risk of jack-knifing.

The heart of the braking system, which as been developed by the Clayton Dewandre Co., Ltd., to meet the specific -equirements of J. Brockhouse and Co., Ltd., is a Hydrovac suspended-vacuum iervo. Its use greatly reduces the delay n the actuation of the semi-trailer brakes -elative to the tractor brakes, which can muse serious instability.

As used with the Brockhouse coupling, he Hydrovac controls a small slave :ylinder connected to a central tongue on he tractor coupling, which, when raised, ipplies the semi-trailer brakes through t peg in the turntable in the conventional nanner. This hydraulic system is indedendent of that of the normal tractor drakes and has a separate header tank.

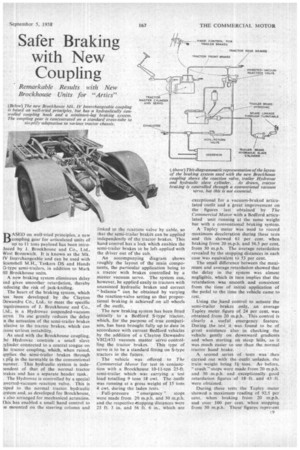

The Hydrovac is controlled by a, special nverted-vacuum reaction valve. This is Diped to the normal tractor. hydraulic iystem and, as developed for Brockhouse, s also arranged for mechanical actuation. Ellis has enabled a small hand control to de mounted on the steering column and linked to the reaction valve by cable, so that the semi-trailer 'brakes can be applied independently of the tractor brakes. This hand control has a lock which enables the semi-trailer brakes to be left applied with the driver out of -the cab.

An accompanying diagram shows roughly the layout of the main components, the particular application being to a tractor with brakes controlled by a master vacuum servo. The system can, however, be applied easily to tractors with unassisted hydraulic brakes and correct " balance " can be obtained by varying the reaction-valve setting so that proportional braking • is achieved on all wheels of the outfit.

The new braking system has been fitted initially to a Bedford S-type tractor, which, for the purpose of true comParison, has been brought fully up to date in accordance with current Bedford vehicles by the addition of a Clayton Dewandre VH2/433 vacuum master servo control ling the tractor brakes. This type of servo is to be a standard fitting on S-type tractors in the future.

The vehicle was offered to The Commercial Motor for test in conjunction with a Brockhouse 10-11-ton 25-ft. semi-trailer which was carrying a test load totalling 9 tons 18 cwt. The Outfit was running at a gross weight of 15 tons 4 cwt. during the laden tests.

Full-pressure " emergency " stops were made from 20 m.p.h. and 30 m.p.h. and the respective topping distances were 25 ft. 3 in. and 56 ft. 6 in.. which are

exceptional for a vacuum-braked articulated outfit and a great improvement on the figures last obtained by The Commercial Motor with a Bedford articu

-Iated unit running at the same weight but with a conventional braking system.

A Tapley meter was used to record maximum deceleration during these tests and this showed 61 per cent, when braking from 20 m.p.h. and 56.5 per cent. from 30 m.p.h. The average retardation revealed by the stopping distances in each case was equivalent t6 53 per cent.

The small difference between the maximum and average retardation showed that the delay in the system was almost negligible, which in turn implies that the retardation was smooth and consistent from the time of initial application of the pedal to the time the vehicle came to rest.

Using the ,hand control to actuate the semi-trailer brakes only, an average Tapley meter figure of 24 per cent. was obtained from 20 m.p.h. This control is clearly a' useful emergency feature. During the test it was found to be of great assistance also in checking, the vehicle gently on downw.ard gradients and when starting on steep hills, as it was much easier to use than the normal tractor hand brake.

A second series of tests was then

carried out with the outfit unladen, the train weight being 5-f tons. Asbefore, " crash "stops were made from•20

and 30 m.p.h. and exceptionally good retardation figures of 18 ft. and 43•• ft. were obtained.

During these tests the Tapley meter showed a maximum reading of 92.5 per cent. when braking from 20 m.p.h. and over 100 per cent. when stopping from 30 m.p.h. These figures represent differences of 17.5 per cent. and at least 30 per cent. respectively, but they are accounted for by wheel-locking and absence of delay in the system.

It was possible to make full-pressure stops with the unladen unit with complete safety, as the outfit pulled up in a straight line on each occasion, although all the wheels were locked for about half the stopping distance from each speed.

None of the brakes had been adjusted immediately before the tests and those on the tractor were found to be out of balance, the off-side brakes tending to take effect before those on the near side. Even so, stability was not affected.

Hand-brake Efficiency While unladen a hand-brake stop was made from 20 m.p.h. and the Tapley meter reading obtained was 30 per cent., both the semi-trailer wheels locking for a distance of 56 ft. The semi-trailer supplied for test had Girling two-leadingshoe 15.25-in.-diameter brakes, the facing width of which was 4.25 in., giving a frictional area of 252 sq. in. for the semitrailer.

The tractor had the standard Bedford brakes, the area of which is 498.4 sq. in. Thus, laden, the outfit had a frictional area of 48.8 sq. in. per ton gross weight.

The • tractor had a VOSR2/812 slave Hydrovac Controlling the semi-trailer brakes and, although a larger Hydrovac can be fitted, the Brockhouse engineers have decided that this would be unadvisable, as it would produce too high a braking effect when a tractor was used with a 6-ton semi-trailer. Thus, much of the merit of the interchangeability of the coupling would be lost unless, of course, the linkages on the 6-ton semitrailer brakes were to be modified to reduce the effort at the shoes.

As with other coupling gears of this type, the new Brockhouse layout has curved loading ramps at the rear. These are steel pressings, up which small rollers on the semi-trailer turntable move when coupling.

Locking System

Locking is controlled by a two-jaw hook assembly which engages on two small rollers near the centre of the semitrailer turntable. The actuation of these jaws is controlled through a hydraulic pump, this reducing the effort required of the driver when uncoupling, particularly on slopes.

Before the lever can lower the locking hook, a separate valve control must be closed. Both the valve and the lever lie below the level of the door sill, so that they do not obstruct access to the driving sat. A microswitch at the hook controls a warning lamp on the dashboard,•this light being illuminated whenever the hook is not fully engaged.

The hook assembly itself consists of two arms joined by a stout tube which forms a grease reservoir to ensure trouble-free operation. The hook is held in engagement by two concentric coil springs which have to be compressed before it can be released. Robust buffer brackets have been so designed as to :esist any tendency for the semi-trailer to c 10 twist about a longitudinal axis relative to the tractor.

At present the 'coupling is offered on Bedford S-type and Austin and Morris Series 111 tractors; but it can be applied to most other tractors which are already suitable for automatic couplings, For this purpose, mounting has been simplified by concentrating all the hook gear on a standard forged cross-tube, which is attached to the inside of the tractor side members by brackets.

Thus, any variation in chassis-frame width can' be accommodated by changing these brackets rather than by altering the cross-tube assembly. The pressed-steel ramps and buffer brackets are bolted to the chassis frame in the conventional way and no welding is employed.

Because of the use of hydraulic control for the hook actuation and a cable control for the hand operation of the semitrailer brakes, there are no direct mechanical linkages between the cab and the coupling or brake gear. Consequently, little modification is required to a standard tractor cab when the new Brockhouse equipment is installed. The semi-trailer, turntable and landin gear are basically unaltered, and al covered by patent No. 786.529. The sem trailer gear includes non-collapsible let as before, but two `slight modifications at the use of an edge-type ratchet for th manual hand brake with a trigger-tyr lever, and a modified king-pin-retainin layout which has provision for shit adjustment to take up wear at the turr table plates.

Standard detachable number-plate an rear-light assemblies, with automati connection for the rear lights, at employed, as with other articulated unii of this type, but stop tamps are als incorporated. These have a separat bayonet socket connection and have t be connected manually.

If a tractor with 24v. lighting wer coupled to a semi-trailer which ha previously been used with a tractor wit 12v. lighting, there would be no risk o

the lights being fused, because both th, rear lamps and the stop lamps of th correct voltage would be transferred Iron the tractor to the semi-trailer whei coupling.