1N-LINE WITH ECONOMY...

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

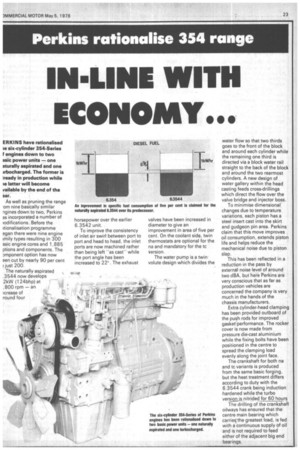

ER KINS have rationalised le six-cylinder 354-Series f engines down to two asic power units — one aturally aspirated and one irbocharged. The former is lready in production while le latter will become vailable by the end of the ear.

As well as pruning the range 'om nine basically similar ngines down to two, Perkins as incorporated a number of iodifications. Before the itionalisation programme egan there were nine engine imily types resulting in 300 asic engine cores and 1,885 ptions and components. The Dmponent option has now een cut by nearly 90 per cent ) just 200.

The naturally aspirated .3544 now develops 2kW (124bhp) at ,800 rpm — an Icrease of round four horsepower over the earlier 6.3542 unit, To improve the consistency of inlet air swirl between port to port and head to head, the inlet ports are now machined rather than being left "as cast'' while the port angle has been increased to 22' , The exhaust valves have been increased in diameter to give an improvement in area of five per cent. On the coolant side, twin thermostats are optional for the na and mandatory for the tc version.

The water pump is a twin volute design which divides the water flow so that two thirds goes to the front of the block and around each cylinder while the remaining one third is directed via a block water rail straight to the back of the block and around the two rearmost cylinders. A new design of water gallery within the head casting feeds cross-drillings which direct the flow over the valve bridge and injector boss.

To minimise dimensional changes due to temperature variations, each piston has a steel insert cast into the skirt and gudgeon pin area. Perkins claim that this move improves oil consumption, extends piston life and helps reduce the mechanical noise due to piston slap.

This has been reflected in a reduction in the pass by external noise level of around two dBA, but here Perkins are very conscious that as far as production vehicles are concerned the company is very much in the hands of the chassis manufacturers.

Extra cylinder-head clamping has been provided outboard of the push rods for improved gasket' performance. The rocker cover is now made from pressure die-cast aluminium while the fixing bolts have been positioned in the centre to spread the clamping load evenly along the joint face.

The crankshaft for both na and tc variants is produced from the same basic forging, but the heat treatment differs according to duty with the 6.3544 crank being induction hardened while the turbo version is nitrided for 60 hours

The drilling of the crankshaft oilways has ensured that the centre main bearing which carries.the greatest load, is fed with a continuous supply of oil and is not required to feed either of the adjacent big end bearings.