HINTS ON MAINTENANCE.

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

616.—An Improvement to the Steering Crossrod Pins of the Peerless.

In many Peerless lorries trouble is experienced due to rapid wear of the pins of the steering crossrod. These pins are hardened and ground, and cost from 6s. to 10s. each, and, apart from this, if they be allowed to remain slack, the holes in the crossrod soon wear oval, sometimes to such an extent that they cannot be bushed. If bushing be possible, the bore of the bushes should be of such a size that the pins are almost a push fit in them.

i The cause of loosening of the pins s that the diameter dowel pin or nib, as it is sometimes called, comes out, thus leaving the pin free to turn in the rod. The probable cause of wear on that portion of the bolt which passes through the knuckle arm is defective lubrication, which is aggravated by road grit. This grit may be prevented from reaching the parts by fitting leather boots.

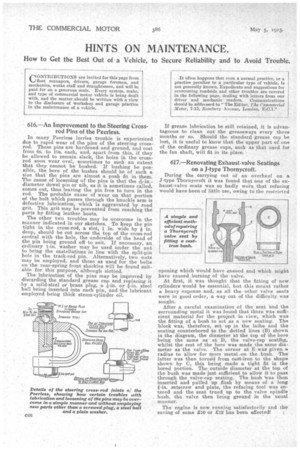

The other two troubles may be overcome in the manner indicated in our sketches. To keep the pin tight in the cross-rod, a slot, 1 in. wide by

deep, should be cut across the top of the cross-rod central with the hole, the underside of the head of the pin being ground off to suit. If necessary, an ordinary 1-in, washer may be used under the nut to bring the castellations in line with the split-pin hole in the track-rod pin. Alternatively, two nuts may be employed, and those as used for the bolts on the rear-spring front shackles will be found suitable for this purpose, although slotted.

The lubrication of the pins may be improved by discarding the standard grease cup and replacing it .by a mild-steel or brass plug, a or g-in, steel ball being inserted into each pin, and the lubricant employed being thick steam-cylinder oil.

If grease lubrication be still retained, it is advantageous to clean out the greaseways every three months or so. Should the standard grease cap be lost, it is useful to know that the upper part of one of the ordinary grease cups, such as that used for the fan shaft, will fit in its place.

617.—Renovating Exhaust-valve Seatings on a J-type Thornycroft.

During the carrying out of an overhaul on a J-type Thornycroft it was found that one of the exhaust-valve seats was so badly worn that refacing would have been of little use, owing to the restricted opening which would have ensued and which, might have caused burning of the valve.

At first, it was thought that the fitting of new cylinders would be essential, but this meant rather a heavy expense and, as all the other valve seats were in good order, a way out of the difficulty was songht.

After a careful examination of the seat and the surrounding metal it was found that there was sufficient material for the project in view, which was the fitting of a bush to act as a new seating. The block was, the'refore, set up in the lathe and the seating counterbored to the dotted lines (B) shown in the diagram, the diameter "at the top of the bore being the same as at D, the valve-cap seatitg, whilst the rest of the bore was made the same diameter as the valve. The corner at E was given, a radius to allow for more metal .on the bush. The latter was then tumid from cast-iron to the shape shown by C, this being made a tight fit in the bored portion. The outside diameter at the top of the bush was made just sufficient to allow it to pass through the valve-cap seating. The bush was then inserted and pulled up flush by means of a long fin, setscrew and plate, the refacing tool was entered and the seat trued up to the valve spindle bush, the valve then being ground in the usual manner.

The engine is now running satisfactorily and the saving of some 210 or £12 has been effected