Forward look ai rear axle ratios

Page 23

Page 24

Page 25

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

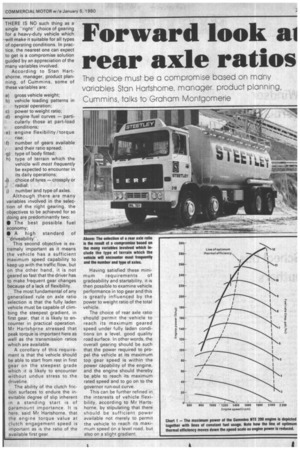

The choice must be a compromise based on many variables Stan Hartshorne, manager product planning, Cummins, talks to Graham Montgomerie

THERE IS NO such thing as a single "rightchoice of gearing for a heavy-duty vehicle which will make it suitable for all types of operating conditions. In practice, the nearest one can expect to get is a compromise solution guided by an appreciation of the many variables involved.

According to Stan Hartshorne, manager, product planning, of Cummins, some of these variables are: a) gross vehicle weight; b) vehicle loading patterns in typical Operation; c) power to weight ratio; d) engine fuel curves — particularly those at part-load conditions; e) engine flexibility /torque rise; f) number of gears available and their ratio spread; g) type of body fitted;

h) type of terrain which the vehicle will most frequently be expected to encounter in its daily operations;

i) choice of tyres — crossply or radial; number and type of axles.

Although there are many variables involved in the selection of the right gearing, the objectives to be achieved for so doing are predominantly two: • The best possible fuel economy;

• A high standard of -driveability".

This second objective is extremely important as it means the vehicle has a sufficient maximum speed capability to keep up with the traffic flow, but on the other hand, it is not geared so fast that the driver has to make frequent gear changes because of a lack of flexibility.

The most fundamental of any generalised rule on axle ratio selection is that the fully laden vehicle must be capable of climbing the steepest gradient, in first gear, that it is likely to encounter in practical operation. Mr Hartshorne stressed that peak torque is important here as well as the transmission ratios which are available.

A corollary of this requirement is that the vehicle should be able to start from rest in first gear on the steepest grade which it is likely to encounter without undue stress to the driveline.

The ability of the clutch friction surfaces to endure the in evitable degree of slip inherent in a standing start is of

paramount importance. It is here, said Mr Hartshorne, that the engine torque value at clutch engagement speed is important as is the ratio of the available first gear.

Having satisfied these mini mum requirements of gradeability and startability, it is then possible to examine vehicle performance in top gear and this is greatly influenced by the 'power to weight ratio of the total vehicle.

The choice of rear axle ratio should permit the vehicle to reach its maximum geared speed under fully laden conditions on a level; good quality road surface. In other words, the overall gearing should be such that the power required to propel the vehicle at its maximum top gear speed is within the power capability of the engine, and the engine should thereby be able to reach its maximum rated speed and to go on to the governor run-out curve.

This can be further refined in the interests of vehicle flexibility, according to Mr Hartshorne, by stipulating that there should be sufficient • power available not merely to permit the vehicle to reach its maximum speed on a level road, but also on a slight gradient.

In this context, Mr Hartiorne suggested a figure of 0.2 0.3 per cent. This would low for slight headwinds or inor gradients without the aed for frequent downranging. For vehicles whichlend the majority of their ierating time on a rolling terin, these figures of 0.2 to 0.3 ir cent could usefully be ineased to as much as 0.5 per nt, claimed Mr Hartshorne.

So far we have concerned irselves with the geared road eed of the vehicle. However, ry few vehicles will operate for qg at such speeds, but will -id to cruise at much lower eeds. The second point for nsideration therefore, is that .3 choice of rear axle ratio is ch that at the normal cruising eed of the vehicle in top gear, 3 engine should be operating a rotational speed close to its .int of minimum fuel conmption.

Fuel economy usually bents when the total number of gine revolutions per mile of irney is kept to a minimum. At 3t sight this suggests a very jh axle ratio so that the engine -otating as slowly as is practiI at the vehicle's cruising aed.

However, Mr Hartshorne argued that this principle could be taken too far and be selfdefeating as if the vehicle geared speed is increased the

-reserve power" is reduced and this may lead to early down changing. The end result therefore will be not a decrease, but an increase in engine revs per mile. Thus there is an optimum point where these engine revolutions per mile are at a minimum, he claimed.

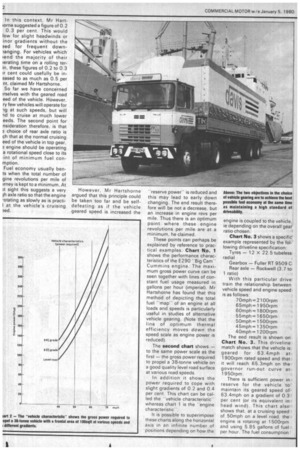

These points can perhaps be explained by reference to practical examples. Chart No. 1 shows the performance characteristics of the E290 "Big Cam" Cummins engine. The maximum gross power curve can be seen together with lines of constant fuel usage measured in gallons per hour (imperial). Mr Hartshorne has found that this method of depicting the total fuel "map" of an engine at all loads and speeds is particularly useful in studies of alternative vehicle gearing. (Note that the line of optimum thermal efficiency moves down the speed scale as engine power is reduced).

The second chart shows — to the same power scale as the first — the gross power required to propel a 38-tonne vehicle on a good quality level road surface at various road speeds.

In addition it shows the power required to cope with sli,ght gradients of 0.2 and 0.4 per cent. This chart can be called the "vehicle characteristic'' whereas chart 1 is the "engine characteristic-.

It is possible to superimpose these charts along the horizontal axis in an infinite number of positions depending on how the engine is coupled to the vehicle, ie depending on the overall gear ratio chosen.

Chart No. 3 shows a specific example represented by the following driveline specification: Tyres — 12 X 22.5 tubeless radial Gearbox — Fuller RT 9509 C Rear axle — Rockwell (3.7 to 1 ratio) With this particular drive train the relationship between vehicle speed and engine speed is as follows: 70mph = 2100rpm 65mph = 1 950rpm 60mph= 1 80Orpm 55mph = 1 65Orpm 50mph = 1 500rpm 45mph = 1 35Orpm 40mph = 1 20Orpm The end result is shown on Chart No. 3. This driveline match shows that the vehicle is geared for 63.4mph at 1 900rpm rated speed and that it will reach 65.3mph on the governor run-out curve at 1 95Orpm.

There is sufficient power in reserve for the vehicle to maintain its geared speed of 63.4mph on a gradient of 0.3 per cent (or its equivalent in head wind). This chart also shows that, at a cruising speed of 50mph on a level road, the engine is rotating at 1 500rpm and using 5.85 gallons of fuel • per hour. The fuel consumption is therefore 8.55mpg (equivalent to 33.1 lit/100km). This operating point (A) is not precisely on the point of maximum thermal efficiency, but is close to it.

Mr Hartshorne said that computation has shown that this gearing gives a first gear gradeability of 27.6 per cent at peak torque speed (1300rpm) and a startability of 15.6 per cent at BOOrpm, so such a vehicle is certainly not overgeared.

But is this the optimum driveline match? There is an indication that higher (ie faster) gearing would benefit the fuel economy. The first question, suggested Mr Hartshorne, is whether there are components available to gear the vehicle slightly higher. In this particular case it is possible to try the RTO 9513 gearbox from Fuller with a 4.11 Rockwell axle. This combination would raise the geared speed from 63.4 to 65.6mph — moving the vehicle load lines to the left. This new match is shown on Chart 4.

The maximum vehicle speed on governor run out at 1932rpm is now 66.7mph vhile at a cruising speed of 50mph on a level road the enline is rotating at 1448rpm and s using fuel at a rate of 5.7 jallons per hour.

This is indicated by point (B) in the graph. The steady state uel consumption of 8.77mpg ir 32.2 lit/100km is about 2.6 ler cent better than the first xample which to a certain. exant is balanced by the reserve orsepower available. At iOmph this is 112bhp which is ome seven horsepower less Ian the first combination.

On the face of it, said Mr lartshorne, there seems little to hoose between these two xamples of gearing. Both hould perform well with about ie same fuel economy, Cumiins experience indicating that lere will be more gear changes ;quired with the 1 3-speed veron which will result in some icrease in average engine revs er mile.

Although Mr Hartshorne iggested that it would be very -nbitious to consider higher .iaring than the two examples )nsidered so far, nevertheless,

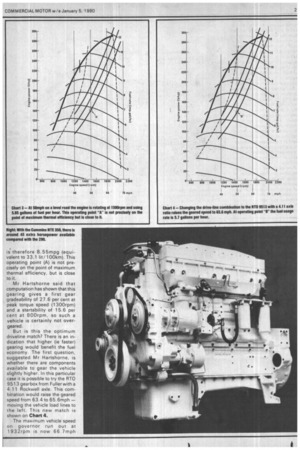

complete the picture an lgineitransmission is consid-ed using the RTO 9513 .arbox and a 3.7 to 1 rear axle tio. This combination would ye a geared speed of 72.9mph 1900rpm (see Chart 5).

Examination of this combination shows that there is insufficient engine power for the vehicle to attain its maximum geared speed of 72.9mph on a level road. In fact, said Mr Hartshorne, it will run out of power at about 1810rpm or 69.4mph. In other words the geared speedability is greater than the powered speedability.

Although Mr Hartshorne suggested that this practice is sometimes used in light/ medium-weight vehicles, it was the opinion of Cummins that it is entirely inappropriate for vehicles in the heavy end of the market. Thus we are back to the first two driveline combinations as being optimum choices giving good driveability and fuel economy at the power-to-weight ratio of 7.2bhp /tonne considered so far.

If a higher power to weight ratio is available then it should be possible to predict with a reasonable degree of accuracy the appropriate vehicle gearing using the same methods already described. The last example clearly overgeared the E290 but how would this gearing look with the NTE 350 engine with its extra 45 horsepower, asked Mr Hartshorne.

Such a match is indicated by Chart 6 which shows that the engine has sufficient power to reach its rated speed of 1900rpm equivalent to 72.9mph while at this same engine speed there is about 0.1 per cent gradeability.

?At a speed of 50mph on a level road (point (C)) the engine is turning at 1300rpm, exactly on its torque peak, using fuel at a rate of 5.68 gallons per hour equivalent to an on-road consumption of 8.8mpg or 2.1 lit/100km. At this point here is 110bhp in reserve, I In Cummins' opinion this gearing is too fast although Mr. Hartshorne suggested that the

,

example is useful to demonstrate the advantages of a high !bower to weight ratio in permitAling higher geared speeds although he doubted the need for geared speeds above 70mph if lower speed flexibility is to be

1Creserved.

• 1 As Stan Hartshorne mentioned, the subject of vehicle gearing presents an ideal opportunity for the various engine and chassis manufacturers to apply today's computer technology. The Cummins system is known as VMS for "'vehicle mission simulation-.

The input data comprises various characteristics from both engine and vehicle including power, fuel delivery rate, gross weight, body shape and size, axle layout and so on. The computer also requires details of the operating conditions such as temperature, wind strength and direction, altitude and type of road surface.

A profile of the road is developed by measuring real roads for changes in direction, gradient, speed limits, etc, with all these variables being stored in the computer's data bank. The computer is then programed to -drive" the chosen vehicle over the particular road system.

The output data is extremely extensive and includes: 11] Steady state data of general speed gradeability and startability in all gears

L Acceleration characteristics on a level road and on gradients 0 Driving time and average speed fl Total fuel used and thus the fuel consumption 0 Average engine revolutions per mile

LI Total number of gear shifts This sophisticated technique permits a rapid analysis of various available engine and transmission alternatives in order to reach the optimum solution for a specific vehicle thus taking a lot of the guesswork out of what is a complex subject.