Axle options aid flexible operation

Page 33

Page 34

Page 35

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

WERATORS can often exend the useful life of a hassis or have a new model lore closely tailored to their eeds by means of an axle onversion. This can either e a trailing axle converting, ay, a two-axle rigid into a x2 or alternatively a twinbeer arrangement, which is uite a popular choice, esacially with the breweries. The conversion from a two to three-axle machine is not )cessarily to take advantage of e 24 tons gross permitted by w. Many six-wheelers gross around 16 tons, so carrying nearly the same payload as the original two-axle machine, but in converted form it can make use of smaller wheels, giving a lower platform height.

York Truck Equipment is one company which offers a variety of additional axle options including its famous trailing axle. The York engineering and service network is based at Corby with 12 branches under its control. All conversion work is done through these 12 branches on a regional basis.

Depending upon the in dividual model under consideration. a chassis extension might also be necessary before a 4x2 can be converted into a 6x2. York obtained engineering approval for both its chassis extension service and the trailingaxle fitment from the chassis manufacturer at the design stage. So an operator wishing to have his vehicle converted can deal directly with York in the knowledge that the work will not invalidate the warranty (if applicable).

A major part of the early conversion work was carried out on two-axle rigids from the importers, but as these manufacturers have gradually expanded their ranges for the UK market they have brought in their own six-wheelers, so the York conversion business has declined slightly in this area.

Many dealers, however, still stock a 4x2 chassis in preference to a six-wheeler because of the flexibility it allows them. The operator can then have a four-wheeler ex-stock or have a six-wheeler following a rapid York conversion — usually in a lot less time than it takes to order a "genuinefactory sixwheeler.

York has quite a useful export business with third-axle conversions doing work for Pegaso and International Harvester for example. The 6x2 Ford Transcontinental is in Europe courtesy of York, which supplies conversion kits for the standard 4x2 version. Around 30 to 40 of these have been built so far.

Two methods

Basically there are two ways of going about a third-axle conversion.

The first is to relocate the drive axle on the existing chassis and merely add the extra axle as it stands. However, in some cases the geometry can be wrong or the welds can be in the wrong place so an extra section is then added to the chassis.

It is difficult to put a definite time on the whole conversion process — the acutal metal work is only part of the job. The operator contacts his nearest York Truck Equipment branch to discuss his requirements.

The branch would liaise directly with the operator as to when the conversion work can take place. All this would probably take a couple of weeks.

Once the chassis is in the work shop, the conversion work generally takes five working days. So if an operator is having an existing chassis converted, then he can continue using it while the paperwork is being sorted out and deliver it the day before into the workshop.

Obviously, the cost of a conversion is going to depend on which particular chassis we are talking about, but a figure of around £3,000 (list) is not too far off the mark.

To give an example related to a specific vehicle, a conversion to a Bedford KH would cost bet ween £3,128 to £3,244 depending upon the wheelbase.

This includes the axle assembly with wedge brakes, 9.00-20 tyres and a frame extension which is necessary on this model.

These figures relate to a conversion carried out on a chassis cab. If the work is to be done on an existing vehicle then either the customer will remove the body or York will charge for its removal and replacement.

One of the advantages claimed by York for the third axle is that braking hop is reduced, thanks to independently oscillating rocker beams which balance out brake torque reaction and thus prevent load transfer under braking.

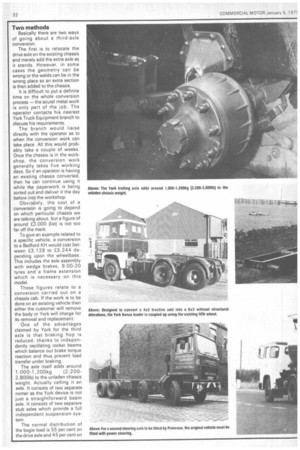

The axle itself adds around 1,000-1,200kg (2:200 2,8001b) to the unladen chassis weight. Actually calling it an axle. It consists of two separate nomer as the York device is not just a straightforward beam axle, It consists of two separare stub axles which provide a full independent suspension system.

The normal distribution of the bogie load is 55 per cent on the drive axle and 45 per cent on the York axle, but if extra traction is required — on site for example — a 60/40 distribution can be obtained using an alternative shackle position.

If required, the York third axle can be fitted with a lifting mechanism which can be used to provide extra traction because of the load transfer capability or to cut down rolling resistance when running empty.

If the 6x2 in question is fitted with a York axle, then fitting the axle lift is no problem. It can be done with someone else's axle but it depends on the individual make.

York has found that these days, most operators going for a third-axle conversion opt for the lifting axle option at the same time. This lifting axle for truck application is now known as Hobo, which is the York trade name for the trailer version only. The extra cost of the lifting system is around £600 over and above the axle conversion.

The Hobo system can be applied to existing trailers if required although it is necessary to weigh up the cost of the conversion against the trade-in value of the old unit against a new Hobo trailer. More expensive items like vans and tankers represent a bigger investment which makes a Hobo conversion more worthwhile. The net conversion price for a Hobo is £920 compared with the £547 when it is fitted as a production unit to a new trailer.

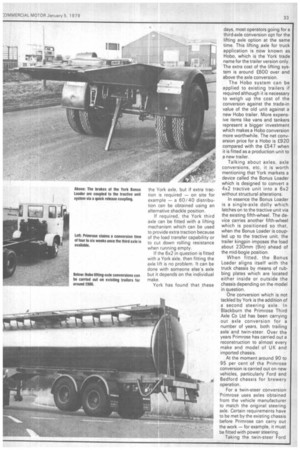

Talking about axles, axle conversions, etc, it is worth mentioning that York markets a device called the Bonus Loader which is designed to convert a 4x2 tractive unit into a 6x2 without structural alterations.

In essence the Bonus Loader is a single-axle dolly which latches on to the tractive unit via the existing fifth-wheel. The device carries another fifth-wheel which is positioned so that, when the Bonus Loader is coupled up to the tractive unit, the trailer kingpin imposes the load about 230mm (9in) ahead of the mid-bogie position.

When fitted, the Bonus Loader aligns itself with the truck chassis by means of rubbing plates which are located either inside or outside the chassis depending on the model in question.

One conversion which is not tackled by York is the addition of a second steering axle. In Blackburn the Primrose Third Axle Co Ltd has been carrying out axle conversion for a number of years, both trailing axle and twin-steer. Over the years Primrose has carried out a reconstruction to almost every make and model of UK and imported chassis.

At the moment around 90 to 95 per cent of the Primrose conversion is carried out on new vehicles, particularly Ford and Bedford chassis for brewery operation.

For a twin-steer conversion Primrose uses axles obtained from the vehicle manufacturer to match the original steering axle. Certain requirements have to be met by the existing chassis before Primrose can carry out the work — for example, it must be fitted with power steering.

Taking the twin-steer Ford D-Series as an example, the original D1010 chassis has to have heavy-duty front springs and steering box before it can be converted to the D141 1 "brewery special". This costs around £2,000 or to be more precise £1,837 plus £204 fitting charge. The equivalent Leyland Boxer conversion would cost £1,850 plus £230. These prices refer to a conversion to a chassis fitted with 17-inch wheels.

For a 20-inch wheel model the total price would be around £2,600. The delivery time is around six weeks from the receipt of the chassis.

The same time scale applies to trailing-axle conversions with the price varying slightly from model to model and wheelsize to wheelsize. With 17-inch wheels, an average cost for the addition of a trailing axle would be in the region of £2,800. For 9.00-20 tyres the cost rises to around £3,100 with £3,300 for 10.00-20 tyres.

As well as carrying out trailing-axle conversions, Primrose will also undertake work on double-drive bogies.

Although the conversion can be done in theory to any vehicle, the price is a lot lower for an Eaton axle. If the vehicle is up to "Primrose spec" with an Eaton axle (in either single or twospeed form) then Primrose will match up to the existing axle for a cost of around £4,700. If someone brings in a non-Eaton vehicle then the conversion cost works out at around £6,000.

A good example of the Primrose ability to extend the useful life of a vehicle is provided by the recent construction of a Volvo F88 eight-wheeler. First registered in 1972, it had been previously a three-axle tractive unit and then a six-wheeled tipper. Being on the heavy side for a six-wheeler, the payload was not exactly exceptional, but converting it into a 30 tons gross eight-wheeler made a lot more sense.

The wheelbase was extended by 500cm (1ft 8in) to meet the outer axle spread requirements and to give a satisfactory weight distribution over the four axles.

Air suspension

If required, York can convert single, tandem and tri-axle trailers to air suspension on York axles. The system uses springs and air bags but instead of the usual Dunlop 405mm (16in) air bags, the York system uses two 250mm (10in) bags which allow the spring centres to be brought further out for greater stability.

York believes that it is the only air suspension available with an axle alignment ability and stresses the importance of this feature by quoting some Goodyear statistics for tyre wear whereby the effect of a quarterinch misalignment is the same as that caused by dragging a 10.00-20 tyre sideways for about 20ft in every mile.

Primrose also fits air suspension — Hands Neway or Dunlop — to either new or existing chassis. In fact a couple of years ago the twin-steer conversions were fitted with air suspension as standard on the secor steering axle, but this was d continued due to licensing pr blems with the manufacturer.

If an operator has a need fot chassis extension — be necessary to allow an extra ax or not — then both York ar Primrose have the expertise advise for or against. There a certain chassis where the fran section would be stretched b this is not an insurmountab problem.

However, cost comes into as most things can be dor technically but not alwai economically.