NOVEL VARIABLE SUSPENSION SYSTEM CRITICISM of the prevailing trend towards

Page 84

If you've noticed an error in this article please click here to report it so we can fix it.

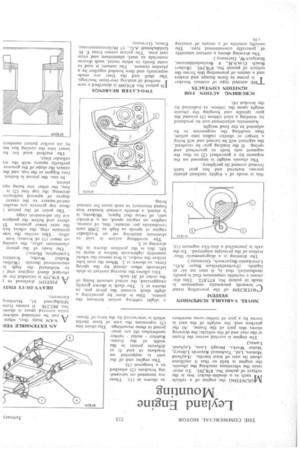

pneumatic suspension is Made in patent No. 877,872. This discloses a variable suspension that is purely mechanical; that is, it uses no air or liquids. (Farbenfabriken Bayer A.G., Leverkusen-Bayerwerk, Germany.) The drawing is a diagrammatic illustration of the principle employed. To the axle is journalled a disc-like segment (1); this is made of a highly resilient plastic porous material and has gear teeth formed around its periphery.

The chassis weight isimposed on the segment by a gearwheel (2) so that the segment acts both as gearwheel and spring. If the loading gear be revolved, the segment will be turned and will bring a longer or shorter radius into action, thus enabling the suspension to be adjusted to the load weight.

Automatic adjustment can be produced by winding a steel ribbon (3) around the gear spindle and hanging the chassis weight upon the ribbon, as indicated by the bracket (4).

SCRUBBING ACTION FOR IGNITION CONTACTS

THE normal type of contact breaker

is prone to form humps and craters and a means of preventing this forms the subject of patent No. 878,395. (Robert Bosch G.m.b.H., 4 Breitscheidstrasse. Stuttgart-W, Germany.) The drawing shows a contact assembly of generally conventional type. The novelty consists of a means of creating c46 a slight rubbing action between the points. This is done by permitting a slight slack around the pivot pin, as shown at I. The slack is shown greatly exaggerated, the actual amount being of the order of .01 inch. • This allows the moving contact to slide leftwards when closed by the spring force, as shown at 2. When the cam lobe strikes the rocker, it first moves the whole assembly rightwards before it starts to lift; this is the position shown in the drawing at 3.

The scrubbing action is said to eliminate misfiring on an 8-cylinder engine at speeds as high as 2,900 cam revolutions per minute; thiS', of course, implies • an engine speed, on a 4-stroke unit, of twice that figure. Hitherto, it is stated, a double contact breaker was found necessary in such cases for correct firing.

TWO-LAYER BEARINGS

I N patent No. 874,049 is described a new method of making two-layer bearings. The shell and the liner are made separately and then bonded together by a plastics cement. The cement is said to unite firmly to white metal, such diverse materials as steel, aluminium and even cast iron. The patent comes from T. H. Goldschmidt A.G., 15 Heitermannstrasse, Essen, Germany,

AN EXTENSIBLE VE11

AVAN body that, when can be extended sidewa■ extra covered space is shows No, 882,258. It comes from Milchgrund 41, Hamburg Germany.

HEAVY-DUTY PISTC A PISTON disclosed in

878,559 is intended for us charged diesel engines and i to withstand the high te encountered therein. (Wellwt Radial Works, Stanforc Lyrnington, Hants.) The body of the piston aluminium alloy, the casting an insert (I) of bronze, iron alloy. This carries the topi pression ring, the others bell the next lower grooves. TI above and below the gudgeol are for oil-control rings.

The point of the patent i three top grooves are machir out-of-square to the extent degree of upward inclinatio drawing, the top line (2) is line, the other one being squ piston.

In use, the piston is hottest fore biggest at the top, and the causes the slope of the grooves perfectly square with the wa cylinder liner.

The method used for bo insert into the casting has be by an earlier patent numbere