With Intent to Improve.

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

A Weekly Summary of Recent Patents, of Interest to the Maker and User of Commercial Motor Vehicles.

Selected and Abridged by H. S. Hall, A.M.I.A.E.

Cylinder Construe tion.

The Daimler Co., Ltd., and A.. E. 13.ntriman describe in specification No. 103,960 an improved construction of cylinder, for an engine suitable for employment upon aircraft and osimilar machines. A plain, cylindrical portion without heavy flanges, on other irregularities, forma 'the cylinder proper This is closed near one end by a diaphragm -integral with the cylinder barrel, which diaphragm has formedin it the valve seats, and on it a central boss. This boss serves to receive the sparking plug, and also in some constructions is screwed externally for the reception of a holdingdown stud for the valve chamber. "The last-named is preferably of aluminium, and fits closely into the recess above the cylinder diaphragm, Which recess . is. formed by the extension of the cylinder Ara% above the said diaphragm.

It will be observed that a cylinder of extremely low weight is secured by this construction: It has, furthermore, the advantage that there is no necessit3i for tla formation of thick flanges, which, besides themselves serving to retain an undue proportion of the heat which would otherwise be dissipated, interfece with the regular spacing of the cooling pins. As will be observd by reference to the drawing which we reproduce, the present construction allows of the coolingfins being continued beyond the . cylinder head. These fins, in the ordinary way, besides suffering interference owing to the formation of flanges, are also reduced owing to the necessity for the fitting and removal of bolts and nuts. Care is taken in the assembling of the cylinder to secure intimate contact between the lower face of the aluminium casting and the upper surface of the diaphragm. The head is secured in place either by a central 'hollow stud screwed on to the outside of the sparking plug boss, or, alternatively, by means of long bolts coupling up to the engine crankcase. Such long bolts are customarily used for fastening the cylinder to the crankcase.

A disadvantage appears to be due to the inaccessibility of the valves; it is evidently.necessary that the cylinder be removed if theSe are to have attention.

In .connection with this invention, but also applicable to any overhead-valve internal-combustion engine, a further patent has been taken out by the same company, No. 103,785, which covers the utilization of six valves d'sposed round a central sparking plug, three valves for inlet, three for -exhaust. It is claimed that by using 'six. valves, the maximum port area is rendered available which is possible on no other oconponent.'

The patent specification covers the method of operating the three inlet valves by means Of one rocking lever, and the three exhaust valves by another.

A Stop Cock.

The same company, together with Mr. Berriman and W. F. 'Brown, draughtsman, describe in specification No. 103,796, a construction of stop-cock suitable for petrol or other fluid. This is of the type in which the valve is formed with two ground faces, one of which beds on the main seating when the valve is closed; the other, when the valve is fully open, serves to prevent the fluid having access to the spindle and gland of the valve, and in which the operation . opening and closing is effected by means of 'a wheel, or similar device so formed as to enclose the gland. In general, it is Pointed out, such valves are so constructed that the stuffing-box which receives the gland is of necessity screwed into the main body of the metal in order to allow of the valve being removed endwise from the space left when the stuffing-box is taken away. As a result, the frequent manipulation of the valve has too often the effect of loosening this stuffing-box, thus allowing leakage. In this patented construction, the inlet portion of the stop cock is screwed into tho main body, the stuffing portion being of such a diameter that when it is removed the valve May be taken out from, the hole, this proceeding being tha reverse of that described above. . The cup-shaped operating wheel, which covers the gland, has suitable holes formed in it though which access can he had to die gland for adjustment.

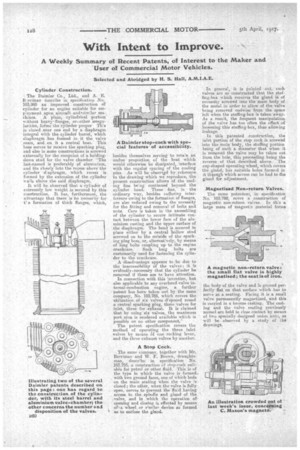

. Magnetised Non-return Valves.

The same patentees, in specification NO. 103,788, cover a construction of magnetic non-return valves. Iii this a large mass of magnetic material forms

the body of the valve and is ground perfectly flat on that surface wIlich has to serve as a seating. Facing it is a small valve permanently magnetized, and this is carried in a bronze casting. The casting and the valve seating previously named are held in close contact by means of two specially designed union nut; as will be observed by a study of the drawings.