For DRIVERS MECHANICS & FOREMEN.

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

A PBIZ E OF TEN SHILLINGS is awarded each week to the Fender of the best 'letter which we publisk on this page ; all others are paid for at the rate of a penny a line, with an allowance for photographs. All notes are edited before being published. Mention your employer's name, in confidence, as evidence of good faith, Address, D., M. and F., " The Commercial Afotor," 7-15 Itosebery Avenue, London, E.G. 1.

Lamps Alight—

'Light your lamps at 5.59 in London, 6.7 in Edinburgh, 3.2 in Newcastle, 6.9 in Liverpool, 6.5 in Biriningham, 6.9 in Bristol, and 6.47 in Dublin.

ABrake Gear Improvement.

The sender of the following communication has been awarded the 10s. prize this week.

[1783] " A.W." (Dewsbury) writes :—" I had been having periodic trouble with the brakes on my steamwagon,, and finally effected a, drastic alteration to them, and as there are many other vehicles of the same make running about it is more than likely that other drivers will be glad to know how their wagon may be improved in this respect. I therefore send you the enclosed sketch [We have had it redrawn and it is reproduced herewith.—En.).

The brakeds put on by means of a screw and nut, and takes effect on two bands which surround drums on the rear road-wheels, one on each. These bands were, as shown in one of the figures on my sketch, each in one piece, and they were lined with copper. They operated by the two ends of the band being squeezed together by the movement of an L-lever. My objection to the arrangement was that the brakes were difficult: of adjustment and had a tendency to stick. I made a new band,II-, in. thicker than the old one, and divided it in the middle. I fastened a lug on to each of the exposed ends, and joined them by means of a bolt and spring as shown. The bolt served as a ready method of adjustment, and the spring kept the band off the drum when the brake was not in use. Each half of the band was lined with three wooden blocks which served excellently as wearing surfaces, and were, moreover, easily renewed."

Getting Home With a Broken Valve.

[1784] " W.B." (Nayland) writes : —" Several methods of getting home with a broken valve have been described from time to time, but one which I adopted the other day, after meeting with such a mishap is, I believe, new. It has the special advantage that the driver is able to continue his journey without waste of petrol. In my ease it was the inlet valve which broke, and after assuring myself that it was beyond repair, I promptly removed it and replaced it by the exhaust valve. I shortehed the tappet to this valve by screwing down, the adjustment, and ran home on the remaining three cylinders. "With the exhaust valve renaoyed, there was no compression in that cylinder, and since the inlet valve remained shut there was no disturbance of the mixture as it was supplied to the other cylinders."

Secrets of Longevity.

[1785] " A S." (Bradford) writes : —" I have often been asked how I manage to keep my chassis running for so long as I do without its being overhauled. Most of the other drivers on the road have noted that I have, not had the vehicle out of service since it 'was purchased two years ago. My invariable reply is that I never overload, I do not race, and that I keep a close watch on the lubrication. Moreover, I grind the valves in at regular intervals, and do not forget an occasional injection of paraffin, which, in my opinion, helps to keep the piston tope free' from carbon.

"I had a peculiar accident recently, coupled with quite an extraordinary piece-, of good fortune. The engine stopped suddenly, and after a time I found that the pump spindle had broken off short close up to the impeller. The shaft, I discovered, was hollow, and, by good fortune, I found that I had a punch in my toolbag the outside diameter of which was exactly the same as the hole in the broken shaft. My procedure was, of course, the obvious one of driving the punch into one piece of the shaft and then pushing the other piece of shaft on to the projecting piece of steel."

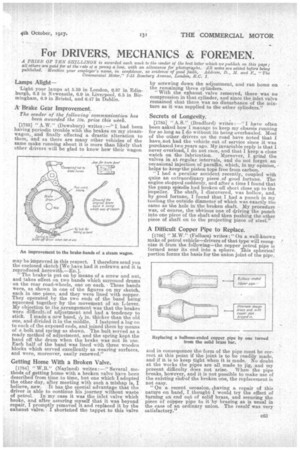

A Difficult Copper Pipe to Replace.

[1786] "MW." (Fulham) writes : "On a well-known make of petrol vehicle—drivers of that type will recognize it from the following—the copper petrol pipe is formed near its end into a. sphere. This spherical portion forms the basis for the union joint of the pipe,

and in consequence the form of the pipe must be correct at this point if the joint is to be readily made, and if it is to keep tight when it is made. No doubt at the works the pipes are all made to jig, and my present difficulty does not arise. When the pipe breaks, however, and it is not possible to make use of the existing achof the broken one, the replacement is not easy.

" Qn a, recent occasion, ihaving a repair of this nature on hand, I thought I would try the effect of turning an end out of solid brass, and securing the piece of copper pipe to it by brazing as is usual in the case of an ordinary union. The result was very satisfactory."