BREWERY F ?I' PROVIDES NATIONNA SERVICE

Page 60

Page 61

Page 62

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

By P. A. C. Brockington,

A.IVI.I.Mech.E.

HEN examining the operations of a large C-licensed fleet during a period of rapid expansion and reorganization of production and distribution methods, it is reassuring to find that its structure is sufficiently flexible to allow for continuous development with out dislocating delivery services. This applies to the trunk and local distribution fleets of Ind Coope, Ltd., the traffic and transport offices of which are at the company's Burton-on-Trent headquarters.

Recent take-overs and production increases have created new problems, and the unsuitability of vehicles acquired in amalgamations has meant the temporary use of nonstandard units. .Although standardization of vehicle types and equipment is fully exploited, organization and control of the fleet are designed to provide for expansion, and, at the same time, to use unsuitable vehicles to the best advantage.

24 Distribution Depots

The three main breweries are at Buron-on-Trent, Romford and Watford, whilst there is a smaller draught-beer brewery at Westerham and lager breweries at Wrexham and Allo-a, Scotland. Local deliveries are made from the breweries and from 24 distribution depots, covering almost the entire conntry. To meet the pressing needs of expansion, several distribution depots will be centralized if facilities are available. _ .

Sub-depots are opened in summer at Blackpool, Canterbury and Haywards Heath. The distribution centres are used for storage only, but there are bottling plants at Cardiff, Plymouth. Llandudno and Oxford.

Ales brewed at Burton-on-Trent include Double Diamond and John Bull, whilst Skol is produced at the lager breweries. Reciprocal agreements with other Companies for the sale of Ind Coope ales involve "extraneous" deliveries in Ind Coope vehicles, which applies also. to loads destined for customers' bottling plants.

Most deliveries from distribution centres to public houses are made in Morris 5-ton platform vehicles. powered by the manufacturers' 5.1-litre oil engine. A few Morris 10-cwt. vans are used for emergency delivery of part-loads.

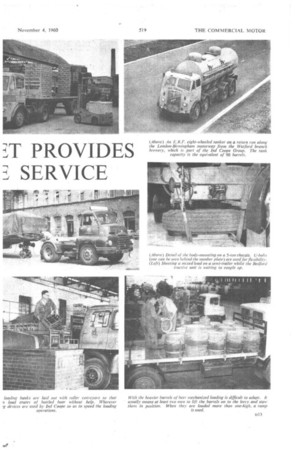

Of the 820 vehicles in the group fleet, 325 are 5-tonners. Accurate planning enables spot deliveries by van, which is relatively costly, to be reduced to a minimum. Some vehicles are used for delivering beer in bulk from the r breweries to distribution centres and customers' bottling plants. They are 10-ton semi-trailer tankers with a capacity.of 50 barrels and hauled by Leyland Comet tractors; 90-barrel tankers based on E.R.F. eight-wheeled chassis; and 75barrel tankers mounted on Albion chassis. The larger vehicles are used mainly for round-theclock trunk runs in two shifts.

Flexibility is achieved by demountable 14barrel tanks, which are loaded on 5-ton platform vehicles. Transporting ale in small tanks is more economical than using hogsheads as .labour charges are reduced for washing-out. One 14barrel, load is equivalent to 10 hogsheads of ale.

In Burton-on-Trent the public-house delivery fleet numbers 60 vehicles, and each covers, on average, 350 miles a week. At Romford 66 vehicles are delivering to public houses, and there will shortly be a further 49 lorries to cater for additional requirements resulting from a take-over. The 26 delivery vehicles at Westerham are employed in transporting draught and .bottled beers from Burton-on-Trent and Rumford.

Local deliveries from the Watford depot are carried out by 47 Commer 7-tonners, equipped with the makers' twostroke engine. These are the only standard public-house delivery vehicles in the fleet which are not of Morris• manufacture.

Rail Not Acceptable

Whilst most of the raw materials are brought to Burtonon-Trent by rail, this form of transport is used only for carrying a small percentage of outgoing traffic and additional loads during peak periods. The staff of the traffic department say that the railways have yet to prove that they can provide an efficient service at an acceptable rate.

In terms of average output of the group, the tonnage of bottled beer carried is substantially higher than that of draught beer in casks, When forecasting transport requirements for the summer season, an accurate estimate of the ratio of bottled beer to draught beer is desirable. This is because the same vehicle capacity is required for carrying 72 gallons of bottled beer and 180 gallons of draught beer, both consignments being equivalent to a I-ton load.

Accurate forecasts of the tonnage of canned beer to be distributed over a busy period are also important. Measured in gallons per ton loaded, canned beer is comparable with casked beer, but has the advantage that the cans do not have to be returned. At peak periods, therefore, hired vehicles carry canned beer in preference to other loads.

Route schedules of the tanker drivers are closely coordinated with brewery requirements to eliminate wasteful running. Two examples may be mentioned to show how typical 11-hour working days of Burton-on-Trent drivers are organized.

On one run, the driver takes an empty 50-barrel articulated tanker to Wrexham, and returns to Burton-on-Trent with a loaded trailer, a total distance of 140 miles. On a second trip with the same tractor, he drives a loaded semitrailer to Burslem, in the Potteries, and returns with a semi-trailer of empties, adding a further 66 miles to the total. All tanker operations are based on an average of 22.5 m.p.h.

In another case, a Burton-on-Trent tractor driver delivers an empty 50-barrel tanker to the brewery in Wrexham, and takes a full tanker 29 miles to Liverpool. The driver returns with an empty unit to Wrexham and hauls a full tanker to Burton-on-Trent, thus covering some 188 miles in the day.

As an example of round-the-clock trunk runs, two 90-barrel rigid tankers cover two return trips in 24 hours from Burton-on-Trent to Romford. Laden on the outward run, the tankers are unloaded by production-department staff and returned to base, laden or unladen. The vehicles are handled by four drivers in the period.

Pallet loading and mechanical handling are applied to all traffic originating at the Romford and Watford depots and to a major part of the Burton-onTrent traffic. New buildings are nearing completion at Romford, and when mechanical handling methods have been reorganized to take full advantage of the facilities offered, this centre will be one of the most modern transport depots in the country.

At the Burton-on-Trent bottling stores, all canned beer is loaded on standard pallets, which are handled by batteryelectric or oil-engined fork-lift trucks. The latter type is used only outside the buildings, because of exhaust fumes.

Pallet loading is applied also to bottled beer if the complete load is destined for a single public house, and experiments are being made with special cases which may enable mechanical handling to be employed for part loads. In a typical multi-drop run, pallets cannot be used, as cases have to be loaded in route-delivery order.

The Morris 5-ton chassis and cabs of the public-house delivery fleets have special platform bodies, built to the design of Ind Coope technicians. Platforms measure 16 ft. 6 in. by 7 ft., and are equipped with stanchions and chains. Keruwin hardwood is used. This combines resilience with a hard surface. The layout of the body members allows flexibility to accommodate chassis flexing.

Other features include 3-in, chock rails, and longitudinal floor planks, which increase the strength of the structure. Timber is preferred to light-alloy materials, because it provides an equal life at relatively low cost, and the wooden floor is safer for loading.

The normal life between replacements of the oil-engined 5-tonners is eight years, whilst the few petrol-engined versions in the fleet last only five. years.

Based on Scammell frames, the 10-ton semi-trailers have reinforced centre members and additional outriggers. The platforms measure 25 ft. by 7 ft. and have hardwood floors. Parts of old Scarnmell 25-ft. semi-trailers are used for constructing vehicles for the company's works fleet.

Cradles of Ind Coope design are fitted to the 50-barrel articulated tankers, which reduce distortion ofthe tank shell by providing improved distribution of loading stresses.

Most tanks have two or three stainless-steel compartments also of Ind Coope design, and are insulated with 2-in. Onozote and pressurized to 30 p.s.i. This ensures that .a constant temperature is maintained for 24 hours to within 3° •F. of the original temperature. The tanks of the maximum-load eight-wheelers have two stainlesssteel compartments with similar insulation, and are equipped with an extended outlet, which eliminates dirt accumulation.

The E.R.F. chassis are powered by Gardner 6LX oil engines and are fitted with power steering and automatic lubrication systems. There are three independent braking systems. Air-pressure retardation is applied to all wheels, in addition to which there is a conventional hand-brake system and a foot-controlled type operating on the wheels of the second leading axle.

A policy of preventive maintenance is applied to all vehicles, and overhauls are carried out in the company's workshops. Regular servicing includes vehicle examination and greasing at 1,000-mile intervals, oil changing at 2,000 miles and docking at 5,000 miles to change filters, test injection equipment and so on. Castrolite oil is used throughout the year.

Tyres are checked daily by the driver and by a mechanic every Saturday. Inspections are made periodically by representatives of the tyre companies. All trailers are equipped with Michelin X tyres, from which favourable mileages are obtained.

Engine and chassis components are stripped for inspection and, if necessary, reconditioned every four years. The 5-tortners complete 100,000 miles in this period, whilst the larger vehicles cover between 150,000 and 175,000 miles. Normal life of vehicles with a capacity in excess of 7 tons is 8-10 years. Although the larger vehicles are in operation for the entire 24 hours of the day, average vehicle availability is better than 98 per cent.

Information given by Mr. B. J. Brennan, the group transport engineer, on motorway running contrasts strongly with the experience of some other operators. Accurate records have shown that tyre wear and, fuel consumption of the larger vehicles running on M1 are comparable with those obtained on other routes. Brakelining wear is reduced by 40 per cent., and there is less wear of

transmissiOn components. Oil consumption is, however. doubled. .

-The safety factor for articulated vehicles is considered to be higher. All " artic " drivers receive special instruction and training in handling this type.

Several vehicles are being used experimentally to assess

their operational suitability. These include an Albion Claymore 5-tonner with underfloor. engine., a Dodge 7tonner, a Thames Trader 7-tonner, and E.R.F. and Thames tractors. The Albion Claymore has a commendable fuel consumption, and drivers appreciate the low cab entrance step. Underfloor engines are not, however, particularly suited to brewery work, -because the power unit is vulnerable to damage by rolling casks._

Bonuses for public-house detivery drivers and mates are payable weekly, the maximum being £2 5s. The standard bonus factor is based on driving ability, but the scheme covers also loading and unloading, delivery to premises, reloading empties and roping down. Payments are proportionate to the overall time saved. An accident-free bonus is also paid to all drivers.

A newcomer to the vehiele staff normally starts as a mate on a 5-tormer, and in time is offered a job as a driver. Later he may graduate to larger vehicles. Drivers are appointed by the traffic department, having been "vetted" by the transport department. Although the driver's duties are restricted to handling the vehicle and helping with deliveries, he is encouraged to develop a "diagnosis faculty and is provided with a 'form for noting defects.