BEARINGS FOR COMMERCIAL VEHICLES.

Page 13

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

The Importance of Accurate Workmanship and Material of the Finest Quality.

THE IMPORTANCE of perfection in the material and. design of ball, roller, or similar bearing•s for commercial vehicles cannot be too strongly emphasized. The work required of such a vehicle, whether it be used for passenger or goods transport, is far in excess of any ever 'imposed on a private ear; and, :unfortunately, commercial vehicles are far more likely to be neglected, because the drivers usually have more work to do than merely driving for a, comparatively, few miles per day, with plenty of time to spare for looking after their machines:

As with magnetos, few, if any, even of the. largest manufacturers produce their own ball or similar bearings. They 'rely on outside sources of supply, and if thee supplies. are not of the finest quality, however much work and however good the 'material which has been put into the finished 'vehicle by the manufacturer, the vehicle will not perform • satisfactorily ; everything, in fact, depends on the bearings. Fortunately, as a whole, these are very reliable, but there is nothing that cannot Ee improved,' and Northern Bali Bearings, Ltd., 115, Great Portland Street, London, W. 1, are now selling bearings incorporating some interesting, new features.

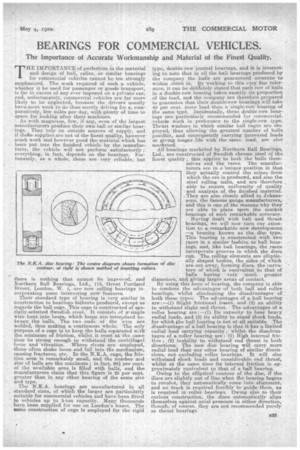

Their standard type. cif bearing is very similar in construction to hearings hitherto produced, except as regards the ball cage. This cage is constructed of specially-selected Swedish steel.It corisiste of asingle wire bent into loops, which loop e are interposed between the balls. The two ends of the wire are welded, thus making a continuous whole. The only purpose of a cage is to keep the balls separated w;th the. minimum of friction, whilst it must at the same time be strong enough to withstand the centrifugal force and -vibration. Where rivets are employed, these often shake loose and fall into the mechanism, causing fractures, etc. In the N.K.A. cage, the friction area is remarkably small, and the number and size of balls are the maximum; in fact., MI per cent: of .the available area. is filled with balls, and the manufacturers claim that this figure is 25 per cent. greater than in any other bearing of the same size and type.

The N.K.A. bearings are manufactured in all standard sizes, of which the larger are partieulgity suitable for commercial vehicles and have been fitted to vehicles up to 5-ton capacity. Many thousands have been supplied for use on London's baseg. The eaane construction of cage is employed for the rigid typo, double-row journal bearings, and it is interesting to note that in all the ball bearings produced by the company the balls are guaranteed accurate to within .00005 in. 4y working to this very fine tolerance, it can be clefihitely stated that each row of balls in a double-row bearing takes exactly its proportion . of the load, anel the company are therefore prepared to guarantee that their double-row hearings will take 80 per cent. more load than a single-row bearing of the same type, incidentally, these double-row hearings are partieularly recommended for commercial. .vehicle work in preference to the single-row type. Thrust washers in which similar ball cages are employed; thus allowing the greatest number of balls possible, and consequently carrying increased loads or giving longer-life with the same load, are also marketed. .

Alf bearings marketed by Northern Ball Bearings, Ltd., are constructed of Swedish chrome steel of the. fwest quality ; this applies to both the balls themselves and the races. The manufacturers are in a 'unique position in that they actually control the mines from which the ore is produced, and also the steel rolling mills, and are 'therefore able to ensure uniformity of quality and analysis of the finished 'material. They are also closely allied to Johanssons, the famous gauge manufacturers, and this is one of the reasons why they are 'able to place upon the market bearings of such remarkable accuracy.

• Having dealt with hall and thrust bearings, we will now turn our attention to a remarkable new development —a bearing known as the dim type. This bearing is constructed with two races in a similar fashion to ball bearings, and, like ball bearings, the races incorporate grooves in which the discs run. The rolling elements are elliptically shaped bodies, the sides of_which are cut away, forming discs, the ourvature of which is equivalent to that of balls having very much greater diameters, and giving larger areas of contact.

• By using this form of bearing, the company is able to combine the advantages of both. ball and -roller bearings, whilst eliminating the •disadvantages of both these types. The advantages of a ball bearing are :—(1) Slight frictional losses, and (2) an ability to withstand slight end thrust. The advantages of a roller bearing are :—(1) Its capacity to bear heavy radial loads, and (2) its ability to stand shock loads, for which theball bearing is not at all suitable. The .disadvantage of a ball bearing is that it has a limited radial load carrying capacity ; whilstthe disadvantages of a roller bearing are; (1) High internal friction; (2) inability to withstand end thrust in both directions. The new disc bearing will carry more radial load than any other bearing of similar dimensions, not excluding roller bearings. It will also withstand shock loads and considerable end thrust, whilst at the same time its internal friction 'is approximately equivalent to that of a bell bearing.

Owing to the elliptical contour of the disc, if the discs are slightly out of line when the bearing begins to revolve, they automatically come into alignment, and no track is required forcibly to guide them, as_ is required in roller bearings. Owing also to their curious construction, the discs automatically align themselves against axial pressure in either direction, though, of course, they are not recommended purely, as thrust bearings.

of disc

In order to prevent the discs from touching each other and consequently causing excessive wear, they are kept apart by-a retaining cage. The sides of this cage are double-bevelled, so that the discs are permitted to rock over slightly, as they automatically do when side thrusts are applied. We extunined discs with which tests have been carried out under actual working conditions and full load for the equivalent of 100,000• miles. These discs were in absolutely perfect condition, and did _not show the slightest signs of wear. Preparations are being made to fit this type of bearingto many sizes of commercial-vehicle wheels, both front and rear, and we shall certainly await with interest the reports on these novel-and well-thought-out bearings. Useful points in their construction are that each disc can be tested by the Brinell test without in any way impairing its rolling surface, and the discs can be inserted between the races without the necessity of providing slots in the latter. The rollers are inserted horizontally, turned up and then turned round.

Preparations are being made on a large scale Lc) undertake the manufacture of these bearings in England.