Silencers for Internal Combustion Engines.

Page 12

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

tConcluded from page 329.

A very efficient silencer is made by the Coventry Motor Fittings Co., Ltd. The principle of Dunlop's second silencer is here simplified, by confining the operations to one central tube. Fig. 17 shows a section of this silencer, which can be compared with Fig. 9 in the issue of this journal for December 21t. The exhaust gases are led into one end of

the central tube, and they pass through holes into one half of the box. The tube is blocked at one-quarter of its length, and the gases re-enter the second quarter, to pass out again through the third quarter into the second half of the box. Thence they again pass into the central tube by the last quarter of its length, and lastly to the atmosphere. The employment of one central tube leads to simplicity of construction, and secures ease in cleaning : the central tube can be unscrewed from the end-plate, after the lock-nut has been removed, and completely taken out for cleaning. Attention must be drawn to the decreasing size of the holes in the central tube.

An extension of the same principle (Fig. 18), where there are four expansions instead of two, is employed on the National cars. A long bolt passes right through the central tube, with a nut at each end : these nuts are not shown in the illustration, as they would tend to hide the details. The end cover, the tubes, and the division plates, can all be removed in one piece, by slacking off the nut at the further end of this central bolt, so that the construction offers no ob

stackto effective cleaning. The holes are very numerous, in order to reduce back pressure, and decrease in size after each expansion, as in the last silencer.

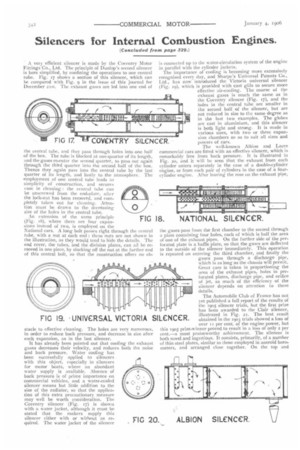

It has already been pointed out that cooling the exhaust gases decreases their velocity, and reduces both the noise and back pressure. Water cooling has been successfully applied to silencers with this object, especially in silencers for motor boats, where an abundant water supply is available, Absence of back pressure is of prime importance on commercial vehicles, and a water-ceoled silencer means but little addition to the size of the radiator, so that the application of this extra precautionary measure may well be worth consideration. The Coventry silencer (Fig. 17) is shown with a water jacket, although it must be stated that the makers supply this silencer either with or without as required. The water jacket of the silencer is connected up to the water-circulation system of the engine in parallel with the cylinder jackets. The importance of cooling is becoming more extensively recognised every day, and Sharpe's Universal Patents Co., Ltd., has now introduced the Victoria universal silencer (Fig. 19), which is provided with cast gills to secure more effective air-cooling. The course of the exhaust gases is much the same as in the Coventry silencer (Fig. 17), and the holes in the central tube are smaller in the second half of the silencer, but are not reduced in size to the same degree as in the last two examples. The globes are cast in aluminium, and this silencer is both light and strong. It is made in various sizes, with two or three expansion chambers so as to suit all sizes and powers of cars.

The well-known Albion and Lacre commercial cars are fitted with an effective silencer, which is remarkably free from back pressure. It is illustrated in Fig. zo, and it will be seen that the exhaust from each cylinder enters separately in the case of a double-cylinder engine, or from each pair of cylinders in the case of a fourcylinder engine. After leaving the rose on the exhaust pipe, the gases pass from the first chamber to the second through a plate containing four holes, each of which is half the area of one of the exhaust pipes. On the further side of the perforated plate is a baffle plate, so that the gases are deflected to the outside of the silencer immediately. This operation is repeated on entering the third chamber, and finally the gases pass through a discharge pipe, which is as long as the chassis will permit. Great care is taken in proportioning the area of the exhaust pipes, holes in perforated plates, discharge pipe, and orifice of jet, as much of the efficiency of the silencer depends on attention to these details.

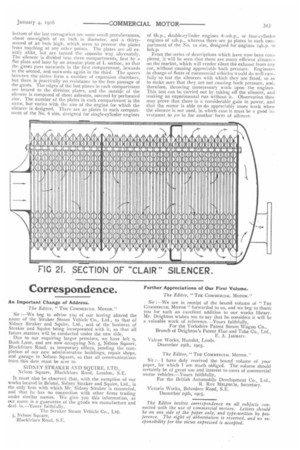

The Automobile Club of France has not yet published a full report of the results of the 1905 silencer trials, but the first prize has been awarded to the Clair silencer, illustrated in Fig. 21. The best result obtained in the 1903 trials showed a loss of over ii per cent, of the engine power, but this 1905 prize-winner proved to result in a loss of only 2 per cent.—a most praiseworthy achievement. The silencer is both novel and ingenious. It consists, primarily, of a number of thin steel plates, similar to those employed in aneroid barometers, and arranged close together. On the top and

bottom of the last corrugation are some small protuberances, about one-eighth of an inch in diameter, and a thirtysecond of an inch high, which serve to prevent the plates from touching at any other points. The plates are all exactly alike, but are turned the opposite way alternately. The silencer is divided into three compartments, first by a flat plate and later by an annular plate of L section, so that the gases pass outwards in the first compartment, inwards in the second, and outwards again in the third. The spaces between the plates form a number of expansion chambers, but there is practically no resistance to the free passage of the gases. The edges of the last plates in each compartment are brazed to the division plates, and the outside of the silencer is composed of sheet asbestos, covered by perforated zinc. The number of the plates in each compartment is the same, but varies with the size of the engine for which the silencer is designed. There are 20 plates in each compartment of the No. 6 size, designed for single-cylinder engines of 611.p., double-cylinder engines 8-ioh.p., or four-cylinder engines of 12h.p., whereas there are 50 plates in each compartment of the No. to size, designed for engines 2411.p. to 8oh.p.

From the series of descriptions which have now been completed, it will be seen that there are many efficient siiencer, on the market, which will render silent the exhaust from any car, without causing appreciable back pressure. Engineer.in charge of fleets of commercial vehicles would do well carefully to test the silencers with which they are fitted, so as to make sure that they are not causing back pressure, and, therefore, throwing unnecessary work upon the engines. This test can be carried out by taking off the silencer, and making an experimental run without it. Observation then may prove that there is a considerable gain in power, and that the motor is able to do appreciably more work when the silencer is not used, in which case it must be a good investment to p-o in for another form of silencer.