Good Features in ANEW KARRIER CHASSIS

Page 68

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

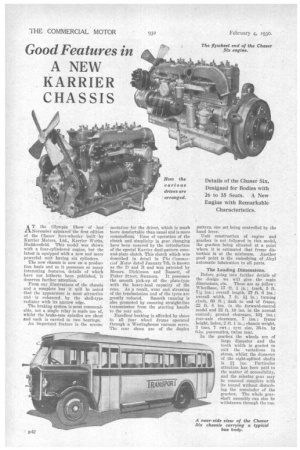

AT the Olympia Show. of -last November appeared the first edition of the Chaser four-wheeler built by Karrier Motors, Ltd., Karrier Works, Huddersfield. This model was shown with a four-cylindered engine, but the latest is equipped with a new and more powerful unit -having six cylinders.

The new chassis is now on a production basis and as it possesses so many interesting features, details of which have not hitherto been published, it deserves further attention.

From our illustrations of the chassis and a complete bus it will he noted that the appearance is most attractive and • is enhanced by the shell-type radiator with its narrow edge.

The braking system is most commendable, not a single relay is made use of, whilst the brake-cam spindles are short and each is carried in two bearings.

An important feature is the wont

modation for the driver, which is much more Comfortable than usual and is more commodious. Ease of operation of the clutch and simplicity in gear changing have been ensured" by the introduction of the special Karrier dual-pattern coneand-plate clutch. This clutch which was described in detail in The Commercial Motor dated January 7th, is known as the D and B and was patented by Messrs. Dickinson and Bassett, of Fisher Street, Swansea. It possesses the smooth pick-up of the plate-type with the heavy-load capacity of the cone. As a result, wear and stressing of the tran'smission and of the tyres are greatly reduced. Smooth running is also promoted by ensuring straight-line transmission from the starting handle to the rear axle.

Excellent braking is afforded by shoes in all four wheel drums operated through a Westinghouse vacuum servo. The rear shoes are of the duplex pattern, one set being controlled by the hand lever.

Unit construction of engine and gearbox is not follawed in this model, the gearbox being situated at a point where it is estimated that frame distortion is at the minimum. Another good point is the embodying, of .Aleyi automatic lubrication to all parts.

The Leading Dili-tensions.

Before going into further details of the design we will give the main dimensions, etc. These are as follow : Wheelbase, 17 ft. 1 in.; track; 5 ft. 74--A. ins. ;'.overall length, 27 ft. 6 ins. ; overall width, 7 ft. n in. ; turning ,circle,. 60 ft.; dash to end of frame, 22 ft. 8 ins, in the forward-control model and 22 ft. 10 ins. in the normal control ; ground clearance, 101 ins. ; rear-axle clearance, 7 ins. ; frame height, laden, 2 ft. 1 in, ; chassis weight, 3 tons, 7 cwt.; tyre size, 36-in. by 6-in, pneumatics, twins rear.

In the gearbox the wheels are of large diameter and the tooth width is graded to suit the variations in stress, whilst the diameter of the eight-splined shafts is 21 ins. Particular attention has been paid to the matter of accessibility, and the selector gear may be removed complete with its tunnel without disturbing the remainder of the gearbox. The whole gearshaft assembly can also be withdrawn through the top.

To avoid drumming the box is webbed • internally at intervals of only 11 in., by small longitudinal 'and lateral webs: Oil leakage is obviated by employing double spring-loaded oil glands. At the rear of the box is the gear drive for the speedometer. In the interests of standardization it may be noted that this gearbox unit is of the same type as is employed on Liverpool's Clipper-type six-wheelers. The four feet of the gearbox casing are bolted to two inverted cross-members of channel section; each of these members is held at its ends to frame brackets by means of large-diameter horizontal pins, the method preventing frame distortion from being transmitted to the gearbox. The gearbox is not stressed by its own weight, and one man can drop the whole unit by first taking ont the two pins at one side and then allowing the box and its support channels to swing downwards. Other good features are the small overhangs for the coupling spiders at the front and rear, this also applying to the split housing of the propeller-shaft bearing, for which two Timken taper-roller races are used.

Gear Ratios and Road Speeds.

We have not yet referred to the gear ratios and the corresponding road speeds at 1,250 r.p.m. of the engine. These are: direct, 5.2 to 1 (25.75 m.p.h.) ; third, 8.97 to 1 (14.95 m.p.h.) ; second, 14.92 to 1 (8.97 m.p.h.) ; first, 25.8 to 1 (5.18 m.p.h.) ; reverse 33.4 to 1 (4 m.p.h.).

Multiple-disc universal joints with suitable centring devices are employed throughout the transmission. An undersjung worm effects the final drive, and the differential gear is of the fourstar bevel pattern. The axle shafts are of special heat-treated 100-ton steel. An I-section beam, tapering to round section to take the stresses from the front-wheel brakes, is employed for the front axle.

• As regards the frame, no drilling has been permittted in either the top or bottom flanges. Channel-section crossmembers brace the side-members between the rear-spring brackets. Care has been taken to avoid an abrupt upsweep over the axle and the amount is approximately 5i ins. Now we come to that very important unit, the engine. Here, again, we find that it is identical in every respect with the type employed in the 1930 model Clipper. This engine has undergone very severe tests, from which it has emerged most successfully. One test consisted of running it dudes full load for 48 hours non-stop at 2,000 r.p.m. It is certainly a notable design. Although compact as a unit, its internal dimensions are generous, and all the ,auxiliaries are accessibly mounted at the near side, with the exception of the water pump and magneto, which are at the front, being cross-driven by spiral gears from the end of the camshaft. The bore of the six cylinders is 100 mm., and the stroke 140 mm., giving an R.A.C. rating of 27.2 h.p. It actually develops on the bench 59.8 b.h.p. at 1,000 r.p.m., and 122.5 b.h.p. at 2,400 r.p.m. although when in the chassis it is choked slightly in the inlet pipe so as to limit the power to 102 b.h.p. sat 2,000 r.p.m. This restriction permits the most economical road setting for power and consumption.

The venturi choke adopted does not interfere.. with the distribution, and a reasonable torque is maintained at low engine speeds. With the overall gear ratios supplied ample reserve of

tractive effort is ensured, whilst the engine revolutions are kept low.

It may surprise many to know that the compression ratio is 6 to 1, this being permitted by the Whatmough head, in which the sparking. plug is mounted immediately over the exhaust valve. This 'head has what is known as differential water cooling and directional flow of the gases, the flow line being blended to continue the lines of the valve head. Oarbtrution is effected by a Soles 46 M.O.H.D.T.

iustrument. • • Te give longitudinal strength the crankcase is split &ins. below the centre line of the crankshaft, and for lateral rigidity it is ribbed internally by six large T-shaped webs. Pour gallons of oil can be carried in the sump, and the oil is pressure-fed to all main and big end bearings. Ample provision is made for oil purification. The crankshaft is hollow and is supported on four bearings, 21 ins, in diameter, the projected area being approximately 34 sq. ins. The material employed is nickel-chrome steel, heattreated to a Brinnel hardness figure of 290. By drilling eccentric holes in the crankpins, the centrifugal load is decreased without reducing the strength. White-metal is run directly into the big-ends, and the gudgeon pins are of the floating pattern. A pump capacity of five gallons per minute at 2.000 r.p.m. ensures the maintaining of the oil-pressure at 25 lb.

The pump is submerged and cannot therefore be starved. Immediately in front of it is a torsional vibration damper. Although the engine is capable of running at speeds up to 4,000 r.p.m., no period is noticeable throughout the range. , Timing Inspection Convenient.

The tappets are formed in two pieces with chilled cast-iron heads pressed into nickel-steel shanks. The ,timing wheels have steel centres and are lubricated from the relief valve. Removal of the timing-ease cover leaves the wheels undisturbed. Provision is made on the camshaft for driving a distributor. A point of interest is that fumes from the crankcase breather are conveyed outside the chassis frame. The price of the Chaser Six chassis is £1,050 either as a forward-control 35-seater or as a: normal-control 26seater. .