I Gas discharge has been used for domestic and sheet lighting for

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

many years. However, the inordinate time these systems take to start and warm up have kept them out of automotive use. But all that has been changed by computer control.

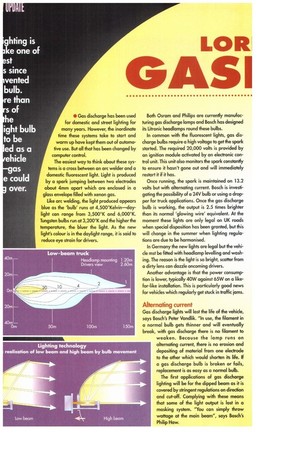

The easiest way to think about these systems is a cross between an arc welder and a domestic fluorescent light. Light is produced by a spark jumping between two electrodes about 4mm apart which are enclosed in a glass envelope filled with xenon gas.

Like arc welding, the light produced appears blue as the 'bulb' runs at 4,500-Kelvin—daylight can range from 3,500°K and 6,000`K. Tungsten bulbs run at 3,200'K and the higher the temperature, the bluer the light. As the new light's colour is in the daylight range, it is said to reduce eye strain for drivers. Both Osram and Philips are currently manufacturing gas discharge lamps and Bosch has designed its Litronic headlamps round these bulbs.

In common with the fluorescent lights, gas discharge bulbs require a high voltage to get the spark started. The required 20,000 volts is provided by an ignition module activated by an electronic control unit. This unit also monitors the spark constantly to ensure it hasn't gone out and will immediately restart it if it has.

Once running, the spark is maintained on 13.2 volts but with alternating current. Bosch is investigating the possibility of a 24V bulb or using a dropper for truck applications. Once the gas discharge bulb is working, the output is 2.5 times brighter than its normal 'glowing wire' equivalent. At the moment these lights are only legal on UK roads when special disposition has been granted, but this will change in the summer when lighting regulations are due to be harmonised.

In Germany the new lights are legal but the vehicle mst be fitted with headlamp levelling and washing. The reason is the light is so bright, scatter from a dirty lens can dazzle oncoming drivers.

Another advantage is that the power consumption is lower, typically 40W against 65W on a likefor-like installation. This is particularly good news for vehicles which regularly get stuck in traffic jams.

Alternating current

Gas discharge lights will last the life of the vehicle, says Bosch's Peter Vandlik. "In use, the filament in a normal bulb gets thinner and will eventually break, with gas discharge there is no filament to weaken. Because the lamp runs on alternating current, there is no erosion and depositing of material from one electrode to the other which would shorten its life. If a gas discharge bulb is broken or fails, replacement is as easy as a normal bulb.

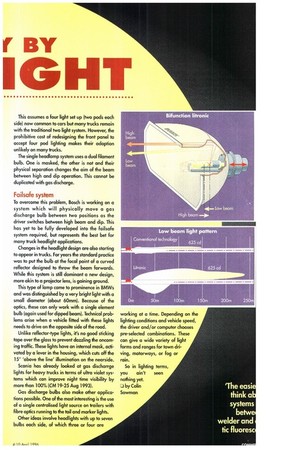

The first applications of gas discharge lighting will be for the dipped beam as it is covered by stringent regulations on direction and cut-off. Complying with these means that some of the light output is lost in a masking system. "You can simply throw wattage at the main beam", says Bosch's Philip Haw. This assumes a four light set up (two pods each side) now common to cars but many trucks remain with the traditional two light system. However, the prohibitive cost of redesigning the front panel to accept four pod lighting makes their adoption unlikely on many trucks.

The single headlamp system uses a dual filament bulb. One is masked, the other is not and their physical separation changes the aim of the beam between high and dip operation. This cannot be duplicated with gas discharge.

Failsafe system

To overcome this problem, Bosch is working on a system which will physically move a gas discharge bulb between two positions as the driver switches between high beam and dip. This has yet to be fully developed into the failsafe system required, but represents the best bet for many truck headlight applications.

Changes in the headlight design are also starting to appear in trucks. For years the standard practice was to put the bulb at the focal point of a curved reflector designed to throw the beam forwards. While this system is still dominant a new design, more akin to a projector lens, is gaining ground.

This type of lamp came to prominence in BMWs and was distinguished by a very bright light with a small diameter (about 60mm). Because of the optics, these can only work with a single element bulb (again used for dipped beam). Technical problems arise when a vehicle fitted with these lights needs to drive on the opposite side of the road.

Unlike reflector-type lights, it's no good sticking tape over the glass to prevent dazzling the oncoming traffic. These lights have an internal mask, activated by a lever in the housing, which cuts off the 15° 'above the line' illumination on the nearside.

Scania has already looked at gas discharrge lights for heavy trucks in terms of ultra violet systems which can improve night time visibility by more than 100% (CM 19-25 Aug 1993).

Gas discharge bulbs also make other applications possible. One of the most interesting is the use of a single centralised light source on trailers with fibre optics running to the tail and marker lights.

Other ideas involve headlights with up to seven bulbs each side, of which three or four are

working at a time. Depending on the lighting conditions and vehicle speed, the driver and/or computer chooses pre-selected combinations. These can give a wide variety of light forms and ranges for town driving, motorways, Or fog Of rain.

So in lighting terms, you ain't seen nothing yet. by Colin Sowman