Building a Bus Body on "Bogies"

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

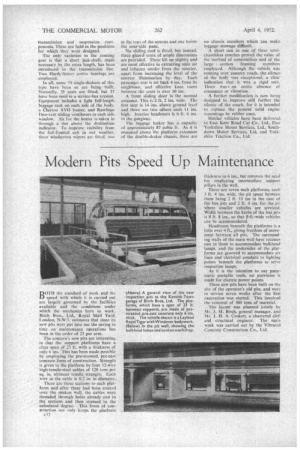

0 NE of the most striking postwar vehicle rehabilitation program-lays carried out by a public service vehicle operator is that of Maidstone and District Motor Services, Ltd. Not only have new vehicles been produced, taking advantage of the latest permissible dimensions, but the method of construction employed represents the most modern practice in vehicle design. Modern vehicles have thus been obtained at an economic figure, and a long, useful life seems assured for them. This has been achieved by employing the semi-chassisless type of construction developed by John C. Beadle (Coaehbuilders), Ltd., Dartford, Kent.

At the end of the war, the company possessed some sound A.E.C. Regent Mk. I and Leyland TD4-5 doubledeckers, to rehabilitate which would have extended their useful life to a possibly uneconomic degree. On the other hand, a need existed for a number of oil-engined coaches to replace petrol-engi ned . vehicles.

Double-decker Units • A . design was„ evolved, for a 30-ft. by 8-ft. coach, with a light-alloy, body using the principles of integral construction. The completed Vehicles,' powered by A.E.C. 7.7-litre or Leyland 8.6-litre engines, employ the suspen7 • sion and transmission: normally fitted in the double-deckers..

The unladen weight is only 6 tons 12 cwt. 2 qrs.,. although staggered luxury seats for 35 passengers .are fitted, and each seat weighs aroki mately 90 lb. •

The method by which weight-saving has been _achieved _ is unusual but successful, for . it . has avoided the dangers of the entirely unconventional while .retaining some advantages of the traditional. .The old double-decker chassis mere stripped and all cornpatients reconditioned as new. Some

new parts, such as' springs, were used in the conversion process.

A section was then removed from the centre of the chassis, the front, from th dumb iron to the. third crossmember, and the rear, from the, platform drop-frame to the cross-member ahead of the front anchorage of the. rear springs, being retained. On top of the frame was mounted a fabricated channel-section longitudinal running the whole length of the body, with the two chassis sub-frames mounted to give a wheelbase of 18 ft. 4 ins. The longitudinal members, in effect, perform thy same function as a long tree-trunk mounted on two bogies. Across the structure are crossmembers formed of light-alloy angle sections back-to-back. extended outside the sub-frame to outrigger panels. A triangular web of 10-gauge alloy is formed between the frame and the longitudinal outrigger panel. At its outside extremity this is capped by a 9-in. channel-section member, running from the extreme •rear of the body to the rear of the front wheel-arches.

The pillars are attached to the outriggers by a simple angle bracket. A similar extruded alloy section is used in the pillars, waist and skirt rail, and a similar but larger section is employed in the cant-rail and bulkhead framing. This is a boxed I-I-section with a central web in. thick. It is extremely strong, yet light, and can be easily bent to provide the necessary curve in the body

sides. •

The advantages, of this unusual method of construction are obvious. In effect, it enables a chassisless structure to be employed without creating complications in mounting engine.

transmission and suspension components. These arc held in the positions for which they were designed. .

The only variation in the running gear is that a short jack-shaft, Made necessary by the extra length, has been introduced in the transmission line. Two Hardy-Spicer centre bearings are employed.

In all, some 70 single-deckers of this type. have been or are being built. Normally, 35 seals are fitted, but 37 have been used in a service-bus version. Equipment includes a light full-length luggage rack on each side of the body. a Clayton AVH heater, and Rawlings Duo-vent sliding ventilators in each side window. Air for the heater is taken in through a slot above the destination indicator. To improve: visibility from the full-fronted cab in wet weather, three windscreen wipers arc fitted, two

atthe tops of the screens and one below

the near-side pane. . .

• No sliding roof is fitted, but instead, three glazed vents of ample dimensions are provided. Theie lift up slightly and are mot. effective in extracting stale air and tobacco smoke from the interior, apart front increasing the level of the interior ifitimination by day. Each passenger scat is set back 4 ins. from its neighbour, and effective knee room between the seals is over 10 ins.

A front sliding door is the normal entrance. This is 2 ft. 2 ins. wide. The first step is 14 ins, above ground level and there are two others each Ii ins. high. Interior headroom is 6 ft. 6 ins.

in the gangway.

The luggage locker has a capacity of approximately 87 cubic ft. As it is mounted above the platform extension of the double-decker chassis, there are no chassis members which can make luggage stowage difficult.

A 'short run in one of these. semichassiSless coaches proved the 'value of the method of construction and of the large section framing members employed. Although the vehicle was running over country roads, the silence of the body was exceptional, a clear indication that it was a rigid unit. There was • an entire absence of resonance or vibration.

A further modification is now being designed to improve still further the silence of the coach, for it in intended to .replace the present solid engine Mountings by rubber ones.

. Similar vehicles have been cleiiverea to East Kent Road Car Co., Ltd., East Yorkshire Motor Services, Ltd., Southdown Motor Services, LW. and Yorkshire Traction Co., Ltd.