LIGHT WEIGH]

Page 116

Page 117

If you've noticed an error in this article please click here to report it so we can fix it.

BODIES to Save Taxation WHEN designing a body with a view to saving weight, the various limits mentioned in the taxation schedule should be kept well in mind. The proprietor naturally wishes that his vehicle shall come within a specified weight rather than just above it, and to facilitate the achievement of this object the coachbuilder should have a weighbridge on the premises, so that the bodywork may be weighed at various stages of its construction.

Weight is saved in building the body, according to the method of mounting adopted, the way in which the framework is arranged, and by a judicious selection of material.

Simple Body Mountings.

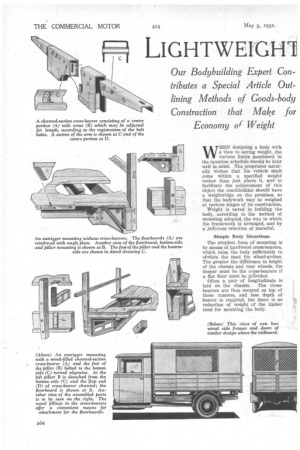

The simplest form of mounting is by means of hardwood cross-bearers, which raise the body sufficiently to obviate the need for wheel-arches. The greater the difference in height of the chassis and rear wheels, the deeper must be the cross-bearers if a fiat floor must be piOvided.

Often a pair of longitudinals is laid on the chassis. The crossbearers are then secured on top of these runners, and less depth of bearer is required, but there is no reduction of weight of the timber used for mounting the body. If the cross-bearer be made of metal, there should be an opportunity for saving weight. This member might be a small lattice girder or be made of pressings.

In order to justify the expense of dies, it is suggested that a cross

bearer be designed which is adjustable for length so as to be used for varying overall widths of bodies. The centre of the bearer is of channel section, inside which is a pair of arms also of -channel section. The arms are drilled and bushed, and the holes register with holes in the centre portion, so that it may be bolted to the arms.

of wood blocks a such thickness as may be required.

By adopting a wheel-arch, deep cross-bearers are unnecessary, and the thickness of the bottom framework is determined by the weight that the floor has to support and the extent of the side overhang. As this overhang is the difference between the width of the body and the chassis, the problem of weight reduction is simplified if the chassis be Wide.

It would be no advantage to make the chassis as wide as the bottom of the body, owing to the weight involved, but the same facility is

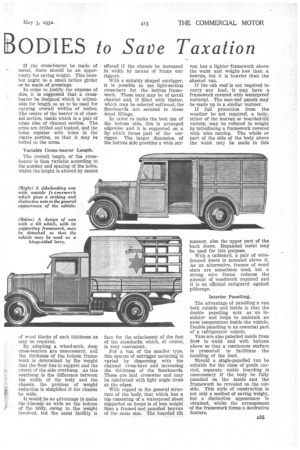

offered if the chassis be increased in width by means of frame outriggers.

With a suitably shaped outrigger, it is possible to use light-section cross-bars for the bottom framework. These bars may be of metal channel and, if filled with timber, which may be selected softwood, the floorboards are secured to these wood fillings.

In order to make the best use of the bottom side, this is arranged edgewise and it is supported on a lip which forms part of the outrigger. The larger dimension of the bottom side provides a wide sur

face for the atiachment of the feet of the standards, which, of course, is very convenient.

For a van of the smaller type, this system of outrigger mounting is varied by dispensing with the channel cross-bars and increasing the thickness of the floorboards. These are laid crosswise and may be reinforced with light angle irons at the edges.

With regard to the general structure of the body, that which has a top consisting of a waterproof sheet supported on hoops is of less weight than a framed and panelled hoxvan of the same size. The boarded tilt van has a lighter framework above the waist and weighs less than a boxvan, but it is heavier than the sheeted van.

If the cab roof is not required to carry any load, it may have a framework covered with waterproof material. The seat-end panels may be made up in a similar manner.

If full protection from the weather be not required, a body, either of the boxyan or boarded-tilt variety, may be reduced in weight by introducing a framework covered • with wire netting. The whole or part of the side of the body above the waist may be made in this manner, also the upper part of the back doors. Entpanded metal may be used for this purpose.

With a tailboard, a pair of wireframed doors is mounted above it. As an alternative, frames of wood slats are sometimes used, but a strong wire frame reduces the amount of woodwork required and it is an efficient safeguard against pilferage.

Interior Panelling.

The advantage of panelling a van both outside and inside is that the double panelling acts as an insulator and helps to maintain an even temperature inside the vehicle. Double panelling is an essential part of a refrigerator vehicle.

Vans are also panelled inside from floor to waist and with battens above so that a continuous surface is presented to facilitate the handling of the load.

Should a single-panelled van be suitable for the class of goods carried, separate ' inside boarding is unnecessary if the body be fully panelled on the inside and the framework be revealed on the outside. This style of construction is not only a method of saving weight, but a distinctive appearance is obtained, whilst the arrangement of the framework forms a decdrative feature,.