Dry Steel Load Led to Rotm

Page 56

Page 57

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

em clock Work

by G. Duncan Jewell

"WORK, work, and yet more work, is the success recipe of the family haulage concern operating as T. Brady and Sons, at Barrow in the North West Lancashire cul-de-sac formed by the Furness peninsula. Because of the geographical situation they have their own peculiar problems in providing road transport for the industrial needs of the area.

Following the example of their father, Mr. Thomas Brady, the Brady boys have always been gluttons for work, and overalls rather than lounge suits are still the order of the day. The number of customers for outward traffic is restricted, and the flow is all in one direction. Customers include such well-known concerns as Thomas W. Ward, Ltd., ship-breakers, the Barrow Steel Works, and British Cellophane, Ltd.

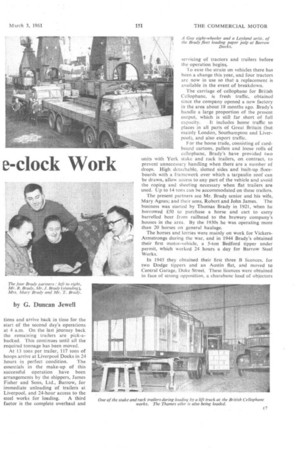

The Brady approach to haulage is well illustrated by the service provided for the transport cif steel baling hoops (12-ft. lengths of steel strip) from Barrow to Liverpool, for export to all parts of the world.

Two 'years ago this traffic, up to 7,000 tons annually, was being carried by rail. An essential feature of its transportation was the necessity of keeping the hoops dry. In damp conditions they are prone to rust and to become unacceptable, shippers being responsible for replacement.

Brady's were given an odd load to take by road which arrived bone-dry at a time when there were many complaints about rust damage on rail.

After negotiation it was agreed that during rush periods, when 100-500-ton lots are required to catch a particular ship, Brady's would provide a round-the-clock service, capable of completing the job in three-four days at 24 hours' notice, using three tractors and nine articulated trailers with three relays of drivers. At the commencement of a job three articulated trailers are loaded the day before, the first shift leaving at 4 a.m. and arriving at North Langton Dock, Liverpool, 90 miles away, at 8 a.m. Trailers are immediately dropped off in the sheds, where Mr. Brady senior and an assistant take over.

The tractors return solo, arriving in Barrow at approximately mid-day, when the second driving shift takes over. Greasing, oiling and filling up are done by the garage staff during the change-over.

E6

During the morning three more trailers have been loaded and returned to the depot by shunt vehicles. The second shift is timed to arrive in Liverpool at 4 p.m., allowing sufficient time for the trailers to be unloaded before the dockers cease work at 5 p.m. On the return journey. empty trailers from the morning shift are brought back to Barrow 133, 8 p.m., when the night shift continue opera

tions and arrive back in time for the start of the second day's operations at 4 a.m. On the last journey back the remaining trailers are pick-abacked. This continues until all the required tonnage has been moved.

At 13 tons per trailer, 117 tons of hoops arrive at Liverpool Docks in 24 hours in perfect condition. The essentials in the make-up of this successful operation have been arrangements by the shippers, James Fisher and Sons, Ltd., Barrow, for immediate unloading of trailers at Liverpool, and 24-hour access to the steel works for loading. A third factor is the complete overhaul and

A Guy eight-wheeler and a Leyland mile. of the Brady fleet loading paper pulp at Barrow Docks.

servicing of tractors and trailers before the operation begins.

To ease the strain on vehicles there has been a change this year, and four tractors arc now in use so that a replacement is available in the event of breakdown.

The carriage .of cellophane for British Cellophane, is fresh traffic, obtained since the company opened a new factory in the area about 18 months ago. Brady's handle a large proportion of the present output, which is still far short of full capacity. It includes home traffic to places in all parts of Great Britain (but mainly London, Southampton and Liverpool), and also export traffic.

For the home trade, consisting of cardboard cartons, pallets and loose rolls of cellophane, Brady's have provided two units with York stake and rack trailers, on contract, to prevent unnecessary handling when there are a number of drops. High detachable, slotted sides and built-up, floorboards with a framework over which a tarpaulin roof can be drawn, allow access to any part of the vehicle and avoid the roping and sheeting necessary when flat trailers are used. Up to 14 tons can he accommodated on these trailers.

The present partners are Mr. Brady senior and his wife, Mary Agnes; and their sons, Robert and John James. The business was started by Thomas' Brady in 1921, when he borrowed £50 to purchase a horse and cart to carry barrelled beer from railhead to the brewery company's houses in the area. By the 1930s he was operating more than 20 horses on general haulage.

The horses and lorries were mainly on work for VickersArmstrongs during the war, and in 1944 Brady's obtained their first motor-vehicle, a 5-ton Bedford tipper under permit, which worked 24hours a day for Barrow Steel• Works, In 1945 they obtained their first three B licences. for two Dodge. tippers and an Austin flat, and moved to Central Garage, Duke Street. These licences were obtained in face of strong opposition, a charabanc load of objectors

making the journey to Kendal for the hearing before the Licensing Authority. By 1947 they were able to obtain three additional B-licensed vehicles-two Dodges and one Austin-for general work over a radius 25-50 miles.

Even in those early days Brady's were adopting the modern practice of operating vehicles to their full economic capacity. In 1947, Bob Brady, in the process of carrying out a tyre check with normal 34 x 7 in. Dunlops, covered 47,000 miles in five months with a 5-ton Austin long-wheelbase tipper, before replacements were required. The vehicle was operating daily from Barrow to Sellafield, Workington and Whitehaven with oxygen cylinders for British Oxygen, Ltd., starting at 5 a.m. It returned to Barrow and took D.A. gas empties to Walton, Liverpool, returning with full cylinders by midnight, ready for the following day.

In 1950 a Dodge was put on contract with Thomas W. Ward, Ltd., carrying scrap metal to all parts of the country.

Real expansion started with denationalization, and between 1955 and the present day, 10 special A licence vehicles were acquired. During the rail strike in 1955, Barrow Steel Works, which depended on the flow of scrap from the three docks at Barrow by rail wagon, appealed to Brady's for help. They procured three worn-out Dodges and patched them up. Ship scrap at that time was cut into pieces 6 ft. x 2 ft. and slung by crane, six pieces a time, into steel wagons. Brady's contrived to keep a flow of 150 tons a day going for three weeks, despite the use of a 2-ton magnet for unloading, which gradually reduced the vehicles themselves to scrap.

In addition to special A licence purchases, Brady's took over the business of M. A. Martin, Dalton, with two vehicles, in 1957; that of J. Wardley and Sons, Milnthorpe, two eight-wheelers on A licence, in 1959, and they also acquired an eight-wheeler on special A licence from Lawson and Ellis, Clitheroe, in the same year.

The present fleet stands at eight eight-wheelers and eight articulated units on A licence, two articulated units and a tipper on contract A licence, and two articulated units and four tippers on B licence. There are 19 spare articulated trailers and three draw-bar trailers. The majority of the heavies and articulated units are of Leyland origin and the tippers are Dodge.

B.T.C. Four-in-Line trailers have been tried over the last seven months and have given excellent service. Brady's are impressed by their performance and the effectiveness of the special-trailer brakes, both air and vacuum, acting on the rear wheels. There are now 12 in the fleet, and two a month are on order for the next six months.

Leyland service after sales is also much appreciated. Only a three-year life for -articulated units is visualized, but Leyland and Dodge rigid vehicle chassis are regarded as suitable for complete rebuilding.

Thirty drivers, five fitters and an office staff of five are employed and there is no room for slackers or clockwatchers, but payment is in proportion tb work done. All drivers' cabs on new vehicles are fitted with heaters, wireless and sun visors.

The growth of the business has rendered the present depot at Duke Street obsolete, and plans are in hand for the construction of premises at the present and at an adjoining site.

Regular trunk services are operated between Barrow and London and there are daily services to South Wales, Southampton and Liverpool. With the growth of their London business amounting to more than 50 per cent, of the whole, Brady's are seeking suitable premises for a depot in the Metropolis.