NEXT PHASE FOR RENAULT

Page 48

Page 49

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

The long-serving 50 Series has a new face and a new heart under its old skin.

Performance and behaviour have both been improved but at a price. 11 Last month's Scottish Motor Show included the usual assortment of face-lifted trucks, but few could boast as many changes beneath the surface as Renault's 50 Series S56. Behind a smoother-fronted cab, for example, was a more powerful Perkins Phaser engine, matched by a sturdier gearbox. A lighter suspension system, powered steering and front disc brakes had also been introduced.

The 50 Series family of high-roof panel vans and chassis cabs and cowls first entered production some eight years ago badged as a Dodge under the Karrier Motors banner, but the range has lost none of the workaday characteristics that have traditionally endeared it to municipal and mini-bus operators. Now, with a more powerful engine options, Renault Truck Industries hopes to boost that popularity even further. The engine choice is between the naturally-aspirated Phaser 90 engine, which develops 62.5kW (85hp) at 2,800rpm with 282Nm (280lbft) of torque at 1,500rpm, and the turbocharged version of the Phaser which is fitted in our S56 test vehicle.

This 80kW (109hp) Phaser 100T provides a marked improvement in overall performance over the Perkins T4-38powered S56 (CM 26 July 1986). The 100T offers 11% more power and torque although peak torque is developed 150rpm further up the rev range at 1,600rpm.

This increased performance, says Perkins, is largely due to the Phaser's fourlobe 'Quadram' combustion chamber.

Combined with a Bosch rotary pump and low-inertia injectors the Quadram design is said to cause more thorough mixing of fuel and air in the cylinders to speed combustion. Perkins also claims reduced emissions, better fuel economy and lower noise levels.

Apart from a beefier Turner 15-290 five-speed gearbox (which is also used in some Leyland Daf Roadrunner models) and low-profile tyres, the current S56 range's driveline ratios and wheelbases are unchanged from last year's road test model, which makes the comparisons between them over our Midland distribution route and the Welsh test route much easier to unravel.

• FUEL CONSUMPTION

Last year the T4-powered S56 returned an overall fuel consumption of 12.51it/ 100Iun (22.6mpg) at an average speed of 69.7km/h (43.3mph). Its best figure of 11.61lit/1101cm (24.3mpg) was achieved on the A road return leg of our Welsh route at an average 62.91un/h (39.1mph).

On a calm day last month, the Phaserengined S56 returned 13.1fit/10Olcm (21.6mpg) at 76.4Iun/h (47.5mph). This was a 4.4% deterioration in overall fuel consumption, but with crisper acceleration, particularly through the upper three gears, its overall journey time was down by almost 10%.

The Welsh A road section revealed a similar picture, with a 4.3% fuel consumption increase of 0.51it/100km (1.0mpg), offset by a 7% increase in speed.

While the cab is quieter by around 2dB(A), thanks to the Phaser's low pressure-rise injection, the engine is noticeably more vigorous, pulling strongly in fourth, right down to around 40km/h (25mph) and lugging down steadily on hills. That tenacity was emphasised when slowed by roadworks at the start of the Monmouth Bypass. Once the dual carriageway had cleared, the S56 was quickly into its stride and up to the legal maximum speed to slash 20 seconds off the previous model's hill climb time. There was also a marginal improvement up the short but severe Wantage Hill.

While the engine's performance is impressive equally on trunk roads, in town and on hills, the extra output is obviously paid for in fuel consumption: the 100T's specific fuel consumption curve shows that its stretches comfortably along the 210g/ kW/hr mark at 1,500-1,900rpm where the engine delivers in excess of 330Nm (2431bft) of torque. This produces extremely good fuel efficiency at road speeds at which the vehicle is likely to spend most of its time, but to obtain the best results for a particular application, an operator needs to specify the right suitable final drive — in the case of the S56110T there are three to choose from.

The fastest 3.91:1 differential fitted to our test vehicle, combined with standard 205/75R 17.5 low-profile radial tyres gives a theoretical maximum speed of 117Icm/h (73mph) at 2,600rpm: 4.27: and 4.87:1 units are also available with the optional FA1 Chrysler Torqueffite three-speed automatic gearbox. They give better gradeability but correspondingly slower top speeds.

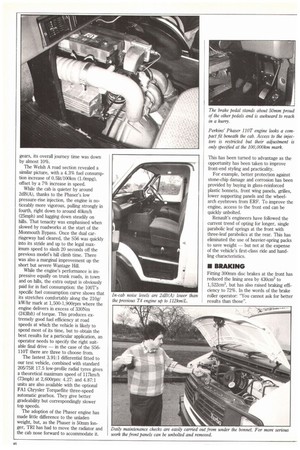

The adoption of the Phaser engine has made little difference to the unladen weight, but, as the Phaser is 50min longer, TRI has had to move the radiator and the cab nose forward to accommodate it. This has been turned to advantage as the opportunity has been taken to improve front-end styling and practicality.

For example, better protection against stone-chip damage and corrosion has been provided by buying in glass-reinforced plastic bonnets, front wing panels, grilles, lower supporting panels and the wheelarch eyebrows from ERF. To improve the engine, access to the front end can be quickly unbolted.

Renault's engineers have followed the current trend of opting for longer, single parabolic leaf springs at the front with three-leaf parabolics at the rear. This has eliminated the use of heavier-spring packs to save weight — but not at the expense of the vehicle's first-class ride and handling characteristics.

• BRAKING

Fitting 300mm disc brakes at the front has reduced the lining area by 430cm2 to 1,522cm2, but has also raised braking efficiency to 72%. In the words of the brake roller operator: "You cannot ask for better results than those". There was too much water about at MIRA to carry out meaningful tests, but a few hard stops from moderate speeds were impressive, A quick dip in the hub-deep wading trough was naturally followed by a loss of braking performance, but this was rapidly regained after a few brake pedal applications. On the test hills the park brake proved to be of an equally high standard, holding the vehicle on a 33% (1-in-3) slope facing both up and downhill. Our only criticism here is that the lever is too close to the floor and sticks before it is fully released. The S56 coped well with most sections of M1RA's punishing ride-andhandling course apart from one section surfaced with the shallow ripples which set up a noticeable vibration at the front end at around 60Iun/h. This did not manifest itself over other corrugated sections of the course.

There were no such ill effects from the ZF8090 Servocom power-assisted steering, which costs 2560 but was effortless and quiet, even at low engine speeds. Earlier S56 models were criticised for their wide turning circles which caused problems when turning in congested streets. RTI has reduced these circles by up to two metres to a more respectable 13.3m for the 3.66m-wheelbase model. One clue as to how this has been achieved lies in the front wheel-arch extensions, which accommodate a slightly wider front beam-axle.

Driving through town centres along our route raised a few points that might otherwise have been missed, such as the excessive height of the brake pedal. When going for the brakes in an emergency, it is possible to catch the side of the pedal with the welt of the shoe and miss the pedal on the first attempt. Familiarity will breed the habit of lifting the leg to corn pensate, but long-legged drivers will have to be alert to avoid being knee-capped by the steering column.

In general the 72% overall efficiency of the brakes is a fair reflection of their performance but they do not feel as responsive as a full-air system. At urban speeds the brakes are effective enough with just light pedal pressures, but to brake hard requires extra effort at the pedal.

• CAB COMFORT

Considering the constraints of its 50 Series cab, Renault has packaged the S56 well. The engine cover restricts left leg movement and the long gear lever prevents easy cross-cab movement, but as a daily work vehicle for short distance delivery work it fits the bill admirably, and for 2630 the optional automatic transmission will ease some of the restrictions.

The cab has a wide entry, comfortable seats and good visibility. Its blue and grey interior looks warm and durable, while the rubber matting is a practical feature. There is also plenty of storage space inside, on the engine cover and in door pockets. By contrast the instrumentation is outdated and at night has to be peered at for information. Surely it would not take too much effort on RTI's part to improve this weak spot in its cab designs. The wide fascia shelf is too smooth, and when objects go sliding past on bends the driver almost expects the lunch-box-type binnacle to follow.

Heavy rain on the distribution route showed up short-comings in the heating and ventilation system. The centre vent was partly restricted, leaving a large area in the centre of the screen uncleared while there is no side flow to clear the door windows. The fresh air ventilation worked perfectly, however.

• SUMMARY

As market leader, the 50 Series has traditionally grabbed the lion's share of the 3.5-7.5-tonne market, but with deregulation, other manufacturers such as Volkswagen and Mercedes-Benz have made serious inroads into this growing market sector, mainly because of increased demand for mini-bus chassis cowls. The restyled, re-engineered 50 Series is Renault's response to that threat. RTI's director of commercial operations Bill Gilliham recently said that sales of the revised 50 Series are expected to rise from 2,500 this year to 2,750 in 1988. The new 556 is a powerful, fuel-efficient range with excellent payload potential which is particularly well suited to distribution work, so Gilliham is not making an idle boast.

Some aspects of its forward-control cab, such as the heating and instrumentation, leave something to be desired, but service intervals extended to 20,000km and the life expectancy of the Phaser put at 350,000km before a major overhaul is needed, the 50 Series will win the vote of many service managers.

0 by Bryan Jarvis