By Laurence J. Cotton, M.1.R.T, Although Specified for a 5-cwt.

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

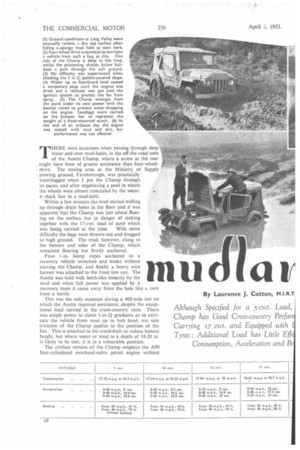

Load Champ has Good Cross-country Peni Carrying 17 cwt. and Equipped with Tyres : Additional Load has Little Eff Consumption, Acceleration and B? THERE were occasions when passing through deep water and over mud-holes, in the off-the-road tests of the Austin Champ, where a screw at the rear might have been of greater assistance than four-wheeldrive. The testing area at the Ministry of Supply proving ground, Farnborough, was practically waterlogged when 1 put the Champ through its paces, and after negotiating a pool in which the wheels were almost concealed by the water, it stuck fast in a mud-hole.

Within a few minutes the mud started welling up through drain holes in the floor and it was apparent that the Champ was just about floating on the surface but in danger of sinking together with the 17-cwt. load of sand which was being carried at the time. With some difficulty the bags were thrown out and dragged to high ground. The mud, however, clung to the bottom and sides of the Champ, which remained floating but firmly anchored.

Four 1-in, hemp ropes anchored to a recovery vehicle stretched and broke without moving the Champ, and finally a heavy wire hawser was attached to the front tow eye. The Austin was held with leech-like tenacity by the mud and when full power was applied by a recovery team it came away from the hole like a cork from a bottle.

This was the only occasion during a 400-mile test on which the Austin required assistance, despite the exceptional load carried in the cross-country tests_ There was ample power to climb 1-in-21 gradients or to extricate the vehicle from mud up to hub level: my sole criticism of the Champ applies to the position of the fan. This is attached to the crankshaft to reduce bonnet height, but where water or mod to a depth of 18-20 in. is likely to be met, it is in a vulnerable position.

The civilian version of the Champ employs the A90 four-cylindered overhead-valve petrol engine without waterproofing, but in all other respects it is similar in specification to the 5-cwt. vehicles as ordered by the Ministry of Supply. With a compression ratio of 7.5 to 1, an output of 75 b.h.p. is obtained at 3,700 r.p.m., and 140-1b. ft. torque developed at 2,000 r.p.m. My tests proved this adequate for payloads up to 17 cwt., which was the maximum carried during the trials, and I am confident that a trailer with an additional load could be hauled where the ground conditions were possibly no worse than a newly ploughed field.

A five-speed gearbox with synchromesh for all ratios is attached as a unit with the engine, and a separate reverse gear is operated by a control attached to the top of the transfer box. In effect, this provides five reverse ratios and the same control operates a power take-off drive for a winch or other attachment. A separate lever, moving a spring-loaded dog clutch, is used in the transfer box to select twoor four-wheeldrive, a further reduction of 1.028 to 1 being introduced when all wheels are driving.

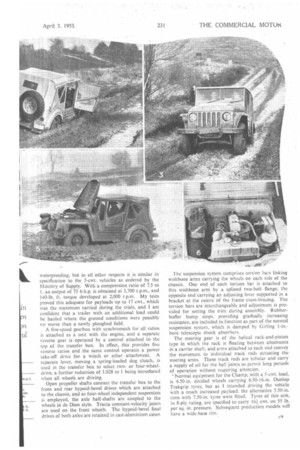

Open propeller shafts connect the transfer box to the front and rear hypoid-bevel drives which are attached to the chassis, and as four-wheel independent suspension is employed, the axle half-shafts are coupled to the wheels in de Dion style, Tracta constant-velocity joints are used on the front wheels. The hypoid-bevel final drives of both axles are retained in cast-aluminium cases. The suspension system comprises torsion bars linking wishbone arms carrying the wheels on each side of the chassis. One end of each torsion bar is attached to this wishbone arm by a splined two-bolt flange, the opposite end carrying an adjusting lever supported in a bracket at the centre of the frame cross-bracing. The torsion bars are interchangeable and adjustment is provided for setting the trim during assembly. Rubberbuffer bump stops, providing gradually increasing resistance, are included to function as part of the normal suspension system, which is damped by Girling 1-in.bore telescopic shock absorbers.

The steering gear is of the helical rack-and-pinion type in which the rack is floating between abutments in a carrier shaft, and arms attached to each end convey the movement to individual track rods actuating the steering arms. These track rods are tubular and carry a supply of oil for the ball joints to permit long periods of operation without requiring attention. "Normal equipment for the Champ, with a 5-cwt, load, is 4.50-in, divided wheels carrying 6.50-16-in. Dunlop Trakgrip tyres, but as I intended driving the vehicle with a much increased payload, the alternative 5.50-in. rims with 7.50-in. tyres were fitted. Tyres of this size, in 8-ply rating, are specified to carry 16 cwt. on 55 lb. per sq. in. pressure. Subsequent production models will have a wide-base rim. Unladen, but with 4 gallons of petrol, hood and sidescreens, the vehicle weighed 11 tons, 17 cwt., being carried at the front and 13 cwt. at the rear. The payloads, which ranged from 5-17 cwt. of sand in bags, were almost totally supported at the rear because even with the 17-cwt. load and driver there was only 1R cwt. imposed on the front wheels.

A 17-cwt. payload was carried on a fuel-consumption test which was staged from Purley to East Grinstead and return, over an undulating route including a few sharp curves which served to test the vehicle's stability at speed. To maintain consistent conditions for the tests, 1 started out at 4 a.m. on a quiet Sunday morning and ran through the complete series with diminishing payloads down to 5 cwt. Apart from milk floats, I had the road to myself for 4-1 hours and the results in fuel consumption and speed were so constant that curves could be completed, with tittle scatter.

A 10-mile run was made to reach normal working temperatures of coolant and lubricants, after which the small fuel tank was brought into use. There was power in plenty even with a 17-cwt. load. The Austin is a lively vehicle and I had no difficulty in keeping the speed to 45-50 m.p.h. even on the up-grades.

As a private-car engine, the A30 unit has a 7.5-to-1 compression ratio, which for optimum performance would operate more efficiently on a good-quality petrol. Because it is not likely to be pampered in this respect, 1 purchased an average commercial grade of fuel.

Meeting a sharp bend at high speed without previous warning, I had difficulty in preventing tail slide. This taught me that with a major overload at the rear the Champ must be treated with respect. Using the corners on the circuit as a guide to fast driving with safety, I found the Austin would behave perfectly with driver, observer and a payload up to 10 cwt., but with 12 cwt and above, some care, according to the degree of overload, was necessary on the sharper bends. This finding coincides with the loads advocated by the'Austin Motor Co., Ltd.

Apart from turning at the end of the course, I had et 0 no need to use indirect gears, and counting the time taken to make the turn, the Austin covered the circuit at 42.2 m.p.h. average speed and gave a fuel return of 16.47 m.p.g. Power petrol was used during the whole period of the test and the Austin performed well on this fuel with little pinking on the hills.

Considering the load and speed, I was pleased with the fuel-consumption figure, hut because of the high power-weight-ratio I found that the weights of the payload made but little difference in m.p.g. The consumption rate improved by small degrees up to 171 m.p.g. when a 5-cwt. load was carried, and the speed remained reasonably constant.

Acceleration trials were made from rest to 30, 40 and 50 m.p.h. and here the Austin showed its paces by reaching 50 m.p.h. in 24 sec. with its nominal load and with 17 cwt. of sand on board it took 13 sec.. longer. There was adequate braking to lock the Wheels with this load and it was only after extended trials with varying degrees of pedal pressure that consistent results were obtained.

(Left) Rubber bump-stops function as part of the normal suspension system of the Champ, which is damped by Girling hydraulic shock absorbers. Tracts constantvelocity joints are employed in the front-wheel drive and the spiral-bevel housing is attached to the chassis.

There was insufficient time to check the total effect on the braking system following the mud bath rwhich the Champ took on the fol' lowing day, but with a 15-cwt. load and 150-lb. pedal pressure, it was found that the wheels were on the point of locking on a dust-free concrete surface.

On the second day Long Valley was shrouded in mist. The initial payload was comprised of an observer and 15 cwt. of sand with a further 3 cwt. in the front of the vehicle to represent a forwardmounted winch. Although it is not practicable to fit a direct mechanical drive to a forwardmounted winch, it could be operated by an hydraulic pump from the gearbox. The ground was in difficult condition, with the furrows practically filled with water, and the soil in other sections heavily churned and broken to a depth of about a foot.

The Champ ploughed into this and came to a stop with wheelspin in the first 100 yd. After removal of the front load the Austin was shunted backward and forward to pack down the soil and eventually it rode free. Still carrying 15 cwt. and a load equivalent to a front-mounted winch, the Champ was headed towards the furrows where, apart from the engine stalling due to water flooding, it came through with a clean sheet.

A second and more ambitious circuit where the going was even worse, saw the vehicle immersed in about 20 in. of water, at which point the engine was flooded by spray lifted by the fan. The engine fired intermittently as the water reached the ignition system and there was no other course but to put a raincoat over the coil, distributor and plugs and to drive with the bonnet raised to prevent build-up of spray. I was relieved when the engine started and continued to fire evenly, and I drove the Champ clear of the pool determined not to attempt any further deep aquatic exercises.

Just ahead there was other deep water but with a harmless-looking mud strip which proffered safe passage. Until coming to a sudden stop, when the vehicle sank to floor-board level, I did not realize the texture of the mud and it was here that the Champ lost all wheel traction and remained buoyed on the surface. The load was shed until the recovery was complete and subsequent tests were confined to less treacherous ground.

The Austin was tested to the extreme. Often it sank deeply in loose -ground and in harder patches it was driven across tracks at high speed to test the suspension. Unquestionably, the torsion-bar linkage provides the answer to smooth travel as the bumps were practically non-existent from the driver's point of view. This was again shown when driving over the paving-stone section at Chobham, where although the wheels were bouncing violently, there was practically no trace of movement on the body.

In the Long Valley manceuvres, part of the front load became dislodged and was lost, so that the remaining tests were made with an imposed weight of 15 cwt. Although the protecting shields and front suspension were often bulldozing a path through the ground, found nothing further to baulk the Champ and thereupon headed it towards Miles Hill for gradient tests.

On an initial run it was driven up the 1 in 21 gradient with a change of gear from second to low half-way up the incline. The next venture was to stop with the wheels resting on the slope for a stop-start trial. It is indicative of the power available that this also was completed satisfactorily, but full throttle was required for take-off and fast climbing. I was doubtful whether the Austin would overcome the layer of rounded pebbles on the loose-surfaced slopes and my first attempt on the 1 in 21 incline ended with wheelspin near the top. From experience of these gradients, then started gathering speed about 30 yd. before climbing, and, using this tactic, the Champ ,stormed up to the top. Further successful attempts were made and finally the Champ was headed towards the steepest of all, which is a 1 in 2.48 gradient. This climb did tax the vehicle and the power was just sufficient to take the Austin and its 15 cwt. over the brow. There was wheelspin, but the vehicle kept moving and I was completely satisfied with all the attempts.

This completed the cross-country section and the vehicle was driven to London before being returned to the works, It was heavily coated with mud which probably increased the unladen weight by 2 cwt. or more. Apart from this no damage was done to the vehicle despite the rough handling it received when the wheels were sunk deeply in the ground. I returned the vehicle, satisfied that it could perform quite reasonably across country, carrying up to 17 cwt. payload and, providing it was not abused on the road, this load could he carried satisfactorily at all times.

If speed is considered essential in road work, I would advocate that the payload should be restricted to 10 cwt, especially where a second man is carried in the cab. The cooling arrangements are adequate and at no time did the water temperature rise above 156 F. with a day reading of 60' F. Oil temperatures were normal at all times.