00MIE

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

• A growing number of operators are turning to aerodynamics in an attempt to cut their truck fuel bills.

Most chassis manufacturers now offer a range of aerodynamic aids for their cabs, and further research has been aimed at providing integrated packages for the whole vehicle — whether box-bodied rigids or tractor/semi-trailer combinations.

Two such projects have received the backing of the Department of Energy. The encouraging results achieved by Exel Logistics with the 17-tonne "Argos Freighter" and TNT with four-axle artic combinations have already been widely covered in the press.

The Government's money didn't stretch to drawbar combinations, however, despite the promise of even better results.

Fortunately the idea hasn't been forgotten. Peter Lane Transport has been running a modified drawbar outfit since last year with some success. It is responsible for the distribution of products to The Body Shop's chain of high street shops.

In the middle of 1990 The Body Shop contract was expanded beyond the South of England to take in the North, and at that point the company took a fresh look at the logistics of the operation.

Peter Lane's contract manager at that time, Mike Wade explains: "We all sat round the table and said 'OK what are the possibilities?'. The result was the demountable drawbar system."

It was decided to use the drawbar to shuttle between The Body Shop's production centre and warehouse at Littlehampton, Sussex, and Peter Lane's base in Normanton, West Yorkshire.

Two rigids would take the demount bodies from Normanton and pass the goods on to the shops.

This would allow the goods to be Loaded in drop order at the Littlehampton warehouse, avoiding the need for additional facilities at Normanton.

Having settled on this concept, and encouraged by The Body Shop's strong environmental policy, Peter Lane examined the options for the detail specification of the trucks.

"We asked the questions: what can we do to improve that vehicle and what is the most fuel efficient option?" says Wade.

The publicity surrounding the other aerodynamic trial led Peter Lane to contact consultant Ricardo AS&A: Even though there were no existing results for drawbars, the performance of the modified rigids and artics convinced Peter Lane to try a streamlined vehicle.

The final system comprised a four-axle Volvo FL10 drawbar combination and two Volvo FL6 17-tonners; all three vehicles were to be optimised for aerodynamics (see panel story), while allowing the nine demountable bodies to be exchanged at random.

Volvos were chosen as they already had a strong foothold in the Peter Lane fleet. The equipment for the drawbar, coupling and demount chassis came from Ray Smith.

The drawbar has been running double-shifts five days a week for just over a year now, clocking up in excess of 230,000km; on its laden journeys it runs at between 25 and 30 tonnes.

Peter Lane has monitored its fuel consumption very closely: 'We have a fuel management system on site here," explains Wade, "and we have also fitted an on-board fuel flow meter." A speed limiter set to 96km/h (60mph) is also used.

The drawbar's average fuel consumption to date works out at an impressive 30.21it/100km (9,35mpg). "On certain journeys we are breaking lOmpg by some margin," says Wade.

However, unlike other aerodynamic truck trials, there is no unmodified vehicle running in parallel with The Body Shop drawbar.

It will not be until larger drawbar fleets try the aerodynamic ideas that the industry will have a clearer picture of their effect.

Internally, Peter Lane has been comparing the drawbar's performance with a four-axle FL10 artic running a box van in similar conditions. This truck has been averaging 35.3lit/100km (8.0mpg), an increase in fuel consumption of almost 17% compared with the drawbar.

Wade describes the financial payback as being "remarkably quick", which seems difficult to believe given that the cost of the aerodynamics for The Body Shop package cost about £15,000.

As he points out, however, this covers the design work for both the drawbar and the two rigids, and the cost of producing the moulds for the aerodynamic panelling.

To cope with the need to extend the distribution work into Scotland, a second aerodynamic FL10 drawbar — this time using a 6x2 chassis — is currently being prepared. Wade believes that the proportion of streamlined vehicles within the Peter Lane fleet is destined to grow.

Until drawbars can operate on equal weight terms with artics, however, we are unlikely to see a rapid expansion in their use. When that day comes aerodynamics will undoubtedly play a major part.

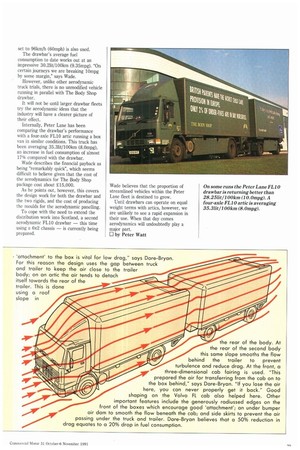

0 by Peter Watt On some runs the Peter Lane FL10 drawbar is returning better than 28.251it/100km (10.0mpg). A four-axle FL10 artic is averaging 35.31it/100km (8.0mpg).