INNOVATION IN ALL SIZES

Page 45

Page 46

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

Two new drawbar outfits dominated this year's transport engineers' show, but there was also innovation aplenty on a more modest scale

• Two novel maximumlength drawbar combinations, among the largest of all the commercial vehicles crammed into Solihull Civic Centre's car park last week, vied for the title of Star of the 17th annual Institute of Road Transport Engineers Display. But there were countless other examples of clever innovation in transport engineering on almost every conceivable scale.

The two drawbars which attracted so much attention were based on a Leyland Cruiser 1126 and Daf 2500 and were exhibited by, respectively, McDonald Kane Material Handling, the Nottingham-based demountable system manufacturer, and Gray and Adams, the refrigerated body builder of Fraserburgh, Scotland.

McDonald Kane's Auto Lift is claimed to be Britain's first "fully automatic" demount system, and this was its first public showing.

It has air-operated twist locks (for which a patent is pending) and electro-hydraulically powered legs, each pair of which can be extended, raised and lowered, and pivoted into its stowed position by an electro-hydrauhc motor of the type commonly used on tail lifts.

The control buttons, both for the legs' motors and the body air-lift bellows on the motive unit and air suspensionraise and lower valve on the trailer, are mounted on a wander lead. The twist-lock control switch is in the cab.

McDonald Kane believes that driver resistance to the chore of manually raising and lowering swap body support legs has been a major factor in some operators' decisions not to move to drawbars and demounts.

The new system will overcome this objection, and has already convinced one big London operator who hitherto used only artics. The combination on display at Solihull was the first of an order for 14, with 28 bodies, which are to be operated by Dodds Transport of Ealing for the distribution of Hitachi UK's products.

The high-specification, 7.3m (24ft) bodies, which are interchangeable between trailer and motive unit, were built by Saxon Coachbuilders of Bedford. Leyland Trucks worked closely with McDonald Kane and Saxon in modifying its Cruiser 16.26 4 x 2 rigid to suit Dodds' specification. This Cruiser is the first to be fitted with Terberg air suspension on its drive axle, as currently being used on French specification Roadtrain tractive units.

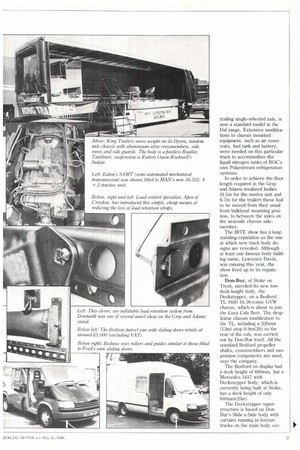

The Daf 2500 6 x 2 drawbar operated by BOC Transhield, exhibited by Gray and Adams, bristles with innovative ideas, ranging from a sliding mounting for the Peitz turntable on the trailer to enable the two bodies in effect to be sealed together during through-loading, to a simple, yet obviously effective, inflatable bag load restraint system. This Danish system comprises long PVC sacks which are fixed to the inner body walls. When inflated, by an air feed from the vehicle's standard air reservoirs, the sacks expand enough to lock in place the unitainers used by BOC Transhield for its Marks and Spencer deliveries.

Daf s TOPEC computer system helped to draw and check the specification of this vehicle, which has been operating out of BOC Transhield's Cumbeniauld depot for about six months. The 6 x 2 2500 rigid, with lifting, trailing single-wheeled axle, is now a standard model in the Daf range. Extensive modifications to chassis mounted equipment, such as air reservoirs, fuel tank and battery, were needed on this particular truck to accommodate the liquid nitrogen tanks of BOC's own Polarstream refrigeration systems.

In order to achieve the floor length required in the Gray and Adams insulated bodies (8.5m for the motive unit and 6.7m for the trailer) these had to be moved from their usual front bulkhead mounting position, to between the axles on the nearside chassis sidemember.

The IRTE show has a longstanding reputation as the one at which new truck body designs are revealed. Although at least one famous body building name, Lawrence David, was missing this year, the show lived up to its reputation.

Don-Bur, of Stoke on Trent, unveiled its new lowdeck-height body, the Deckstepper, on a Bedford TL 1630 16.26-tonne GVW chassis, which is about to join the Coca Cola fleet. The dropframe chassis modification to the TL, including a 330mm (13in) step 0.9m(3ft) to the rear of the cab, was carried out by Don-Bur itself. All the standard Bedford propeller shafts, crossmeinbers and suspension components are used, says the company.

The Bedford on display had a deck height of 680mm, but a Mercedes 1617 with Deckstepper body, which is currently being built at Stoke, has a deck height of only 640mm(25in).

The Deckstepper superstructure is based on DonBur's Slide-a-Side body with curtains running in bottom tracks on the main body sec tion. The front section of the Coca Cola body is a separate compartment used for carrying carbon dioxide cylinders. The main body section can carry 10 pallets. Internal height in the dropped section is 2.16m(7ft 1n).

Don-Bur's second new body at Solihull was in the livery of Federal Express, and was an air-freight version of the Slide a Side body, with six Hydraroll air-operated roller tracks.

Last year. King Trailers displayed its Dyson Superlight semi-trailer with a Southtields postless curtain sided body to Scottish and Newcastle brewer's specifications. This year, the end user was the same, but the postless curtainsider was Boalloy's new Tautliner. The complete tandem axle semi-trailer has a kerb weight of less than 5,200kg.

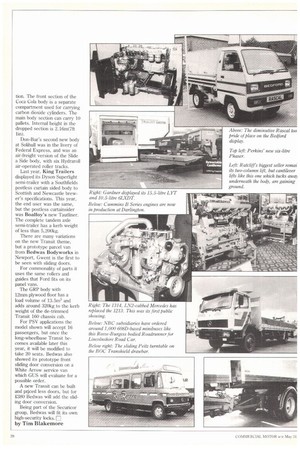

There are many variations on the new Transit theme, but a prototype parcel van from Bedwas Bodyworks in Newport, Gwent is the first to be seen with sliding doors.

For commonality of parts it uses the same rollers and guides that Ford fits on its panel vans.

The GRP body with

12mm plywood floor has a load volume of 13.5m3 and adds around 320kg to the kerb weight of the de-trimmed Transit 160 chassis cab.

For PSV applications the model shown will accept 16 passengers, but once the long-wheelbase Transit becomes available later this year, it will be modified to take 20 seats. Bedwas also showed its prototype front sliding door conversion on a White Arrow service van which GUS will evaluate for a possible order.

A new Transit can be built and priced less doors, but for £380 Bedwas will add the sliding door conversion.

Being part of the Securicor group, Bedwas will fit its own high-security locks.

by Tim Blakemore