WAYS AND MEANS.

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Contributions From Our Driver and Mechanic Readers.

To Rectify Rattling in Wood Wheels.

THERE are very few lorries of British make now running on wooden wheels, but some of the American war-time lorries are still in use, so the experience of a driver of a Peerless lorry, " R.P.," of Cubitt Town, may be of considerable value to all who have to deal with wooden wheels.

Our correspondent found that, through the shrinkage of the wood, he had considerable trouble with his wheels, the looseness, once started, became rapidly worse, so something had to be done. He therefore hit upon the idea of pouring molten white-metal into the gaps between the spokes and the lint. To do this effectively he jacked up the axle until the hub was as nearly central • as possible, then he tacked pieces of wood to each side of two spokes, forming a trough, into which he poured the molten white-metal. Having done this between one pair of spokes, he reversed the position of the wheel and treated the opposite pair of spokes in the same manner ; then, turning these two pairs 'so that they were opposite to each other in the horizontal plane, he filled in others, and so on until he had gone all round the wheel. He assures us that he has now driven this lorry, carrying five-ton loads, for 12 months without the least trouble with his wheels. The same plan might he adopted where the spokes meet at the hub.

A New Use for Old Magnets.

ANYTHING that will help in the de tection of slight cracks in such parts as steering arms, stub axles, etc., should be of value to•those who are concerned with maintenance. Various tests, such as ringing the suspected parts when suspended, rubbing in graphite mixed with glycerine and wiping the surface clean, then subjecting the part to beat, or blows, to cause the graphite to exude, and so show up where the crack is, have been tried, but only with limited success.

A plan is recommended by a correspondent, " HAL," of West Bromwich, which he tells us will detect the finest cracks in any article that may be suspected and, therefore, undergoing examination. The plan he suggests is that of covering the suspected part with a thin film of paraffin, with which should be mixed fine iron filings. A magnet is then placed on each side of the part where a flaw may be suspected in such a iiianner that the lines of magnetic force run at right angles with the possible crack. If any crack is there, the lines of magnetic force will form poles across it and the filings will adhere to the crack and show up plainly its whereabouts.

A Get-you-home Dodge.

ONE of our readers, " C.A.S.," of Wortley, near Sheffield, tells us how he was called upon one evening to help to rescue a vehicle in which the boss had broken away from the flange on the driving side of one hub. The vehicle being of American make, and no well-equipped garage being at hand, he was faced with a very serious problem, as no replacement parts could be procured and no means of repairing the damage was available.

Fortunately, the nut on the end of the axle prevented the wheel from coming off altogether, but there was nothing th make the axle drive the wheel. Our correspondent was therefore faced with the problem of fixing up some temporary means for connecting the axle and the wheel so that a drive could be effected. After trying several spanners, none of which would fit the nut on the axle sufficiently well to be relied upon, he thought of a Stillson pipe wrench, which he adjusted to fit the net, and lashed firmly to one of the spokes of the wheel, after inserting a piece of wood to make up the space between it and the spoke. When all was ready, our correspondent had some fear that the thread on the end'of the axle might twist off, also that the lashing might not stand the strain. He told the driver to drive slowly and to avoid any jerking through letting his clutch in too suddenly. With fear and trembling he watched the driver glide gently away, and after following him for two miles decided to let him complete the rest of his journey, as all seemed to be going well.

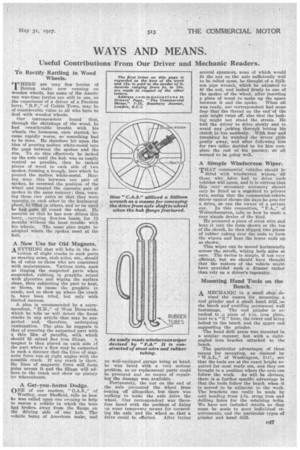

A Simple Windscreen. Wiper.

THAT commercial vehicles should be fitted with windscreen wipers, all those Who have, had to drive such vehicles will agree, and it is curious that this very necessary accessory should only be fitted as a standard to private cars, seeing that the commercial-vehicle driver cannot choose the days he goes for a drive, as can the owner of a private car. In this connection, " F.A.," of Wolverhampton, tells us how he made a very simple device of the kind.

He procured a piece of stout wire and bent it into the form shown at the top of the sketch, he then slipped two pieces of rubber tubing over the ends to form the wipers and bent the lower ends up as shown.

This wiper can be moved horizontally across the scree% wiping both sides at once. The device is simple, if not very efficient, but we should have thought that the makers of the vehicle might have provided such a fitment rather than rely on a driver's ingenuity.

Mounting Hand Tools on the Bench.

A 3100ErAN-Ic in a small shop devised the means for mounting a tool grinder and a mallhand drill. on the bench and avoiding permanent wall

fastenings. The tool grinder is at tached to o. piece of iron plate, bent to a Z "form, the lower end being bolted to the bench and the upper end supporting the grinder.

The hand drill press was mounted in a similar manner, but with a rightangled iron bracket attached to the bench.

The particular advantages of these means for mounting, as claimed by " W.A.L.," of Washington, D.C., are that the tools are at the exact height required for most ready use, and they are brought to a position where the eyes can follow the work. As will be obvious, there is a further specific advantage in that the tools follow the bench when it is moved to be adjacent to the work. The brackets can easily be made by cold bending from Fin. strap iron and drilling holes for the retaining bolts. We have not included details as they must be made to meet individual requirements, and the particular types of grinder and hand drill.