• A conventional, mechanical or electronic fuel system has two

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

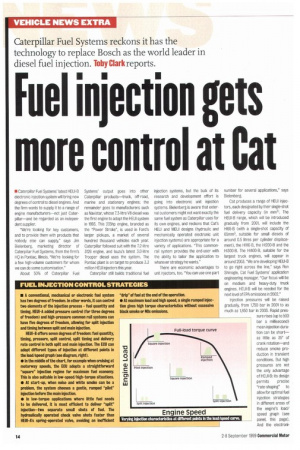

degrees of freedom, In other words, it can control two elements of the injection process fuel quantity and timing. HEUI-A added pressure control (for three degrees of freedom) and high-pressure common rail systems can have five degrees of freedom, allowing for split injection and timing between split and main injection.

HEUI-B offers seven degrees of freedom: fuel quantity, timing, pressure. split control. split timing and delivery rate control in both split and main injection, The ECU can adopt different types of injection at different points in the load/speed graph (see diagram, right).

• In the middle of the chart, for example when cruising at motorway speeds, the ECU adopts a straightforward "square" injection regime for maximum fuel economy. This is also suitable in low-speed/high-torque situations, • At start-up, when noise and white smoke can be a problem, the system chooses a gentle, ramped "pilot" injection before the main injection, • In low-torque applications where little fuel needs to be delivered, it is most efficient to deliver "split" injection—two separate small shots of fuel. The hydraulically operated check valve shuts faster than HEUI-A's spring-operated valve, avoiding an inefficient "drip" of fuel at the end of the operation.

• At maximum load and high speed, a single ramped injection gives high torque characteristics without excessive black smoke or ?Mx emissions.