Patents Completed.

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

Albion Final Drive. Pneumatic Shock Absorber. Butler Axle Design.

F. HENDERSON and ALBION MOTOR CAR. CO., LTD., No.17,564, dated 31st July, 1913.—This specification describes a rear-axle and driving gear which is particularly suitable for heavy vehicles requiring considerable speed-reduction between the, engine and the driving wheels.

The fixed rear-axle is hollow, and two driving shafts extend through it from the differential gear in the middle, one to each road-wheel. At its outer end each of these shafts carries a pinion meshing with a series of smaller pinions mounted on spindles around it. These spindles are carried on a spider fixed on the end of the dead-axle, and the pinions gear in the usual manner with an internally-toothed wheel secured tv, or integral with, the road wheel.

The road-wheel itself is suitably bushed and is free to rotate on the tubular dead-axle.

A cover plate is provided on the outside of the gear to retaiji the lubricant and to exclude dust.

The brake drum is mounted on the inside of the road-wheel, and is provided with a fixed disc, which carries the brake, serves to exclude dust, and prevents leakage of oil front the inner end of the hub.

P. D. BOSWORTH, No. 5963, dated 9th March, 1914.—In the construction of wheel illustrated in this specification two broken wedge-shaped rings are provided, to lie against the felloe-band. One of these is positioned at each side of the wheel, and they are both bevelled in the same direction. The band to which the tire is vukanized is provided with two sloping faces, which co-operate with the two wedge-rings, and an annular rim is provided to hokl the tire at one side of these :jugs.

This tire is put in place in the following manner. The righthand wedge-ring is placed on the felloe-band. The left-hand wedge-ring is then inserted in its place on the tire, and the two together are slid sideways on to the wheel. The detachable rim on the left-hand ,side is then put ill place, and the bolts passed through the rim and screwed up. The tightening causes the tire to be wedged on to the two rings, each of which is separately held in position by lugs engaging the edge of the feline-band or the rim, J. P. Sucsor. 13,364, dated under International Conven tion, 15th January, 1913.--This specification describes a shockabsorber of the hydro-pneumatic type, in which the return movement is retarded by the compression of air in a separate compartment. In the form of apparatus illustrated a hollow cylinder, partly filled with liquid, has a second smaller cylinder sliding in it like a piston. Suitable packing rings ate provided, to make a t ;.,ht joint in conjunction with the liquid, and the smaller cylinder is of such a size that there is an annular space between it and the outer cylinder. If the vehicle wheel encounters an obstacle the shock causes the axle to rise relatively to the chassis. The smaller cylinder then descends in to the larger one and compresses the air contained between them. The liquid within the two cylinders transmits the pressure and causes the packing rings to be pressed more tightly against the wall, thereby preventing leakage and slightly increasing the friction. The downward movement of the smaller cylinder draws air into the annular space surrounding it, and when it tries to move upwards again it compresses the air, which can escape only very slowly.

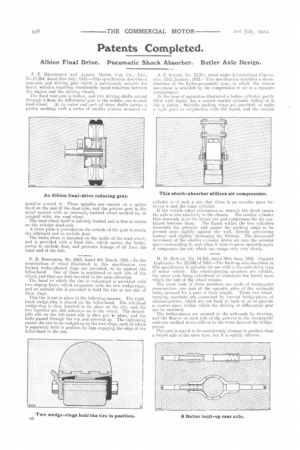

H. M. T3t-nne, No. 14,763, dated 26th June, 1913. Cognate Application No. 23,092 of 1913.—The built-up axle described in this specification is suitable for use with a live-axle-drive type of motor vehicle. The wheel-carrying members are tubular, the outer ends being cylindrical to constitute the barrel upon which the hub of the wheel rotates.

The inner ends of these members are made of rectangular cross-section, one pair of the opposite sides of the rectangle being grooved for a part of their length. These two wheelcarrying members are connected by curved bridge-pieces of channel-section, which are set back to back so as to provide a central space within which the driving or differential gear can be mounted.

The bridge-pieces are secured to the axle-ends by riveting, and the flenees on each side of the grooves in the rectangular ends are caulked down cold on to the outer face-sof the bridgepieces.

This axle is stated to be considerably cheaper to produce than a forged axle of the same type, but it is equally efficient.