fro. Drivers &Mechanics

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best corn. munication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Send IS an account of any sbecial incident of your work or experience.

If suitable, we edit your 710i0.5, supPly a sketch when required, and toy ,..cev far everything published. Mention your employer's name, in confidence. as evidence of good faith. Address to The Editor, THR COMMERCIAL !dorm Rosebery Avenue, licaidon, E.C.

Light Up Your Lamps at 9.18 on Thursday ; 9.18 on Friday ; 9.17 on Saturday; 9.17 on Monday ; 9.17 on Tuesday ; 9J0 on Wednesday.

White-metalling Bearings in a Mould.

The sender of the following communicationhas been awarded the Ws. prize this week.

[1333] " II.31." (West Bromwich) writes :—" For relining gun-metal brasses with white metal I have seen several different methods published in your D. and

M.' pages from time to time. Very few have given the complete information which is required by a novice to do the job without additional help. I enclose, therefore, a sketch—[We have had this redrawn. —E.]—and description of a method which I have used with success for some time.

" I first secure a wood box and fill it ii ith plaster of Paris mixed to the consistency of a thick paste, and then embed the bearings in the plaster, as shown in the first sketch, where a double-flange and a singleila,nge bearing can he seen in position. A piece of steel is then turned to the exact size of the shaft, after the latter has been trued up. This mandrel is provided with flanges, which fit over the ends of the brasses and prevent the white metal from leaking out. . " The mandrel for each brass is pushed down into the necessary position in the plaster, and the latter allowed to solidify. It may be more convenient to cut the mandrel in halves and fit each half with a handle made of a screwed piece of wire for ease in withdraw ing. If radii are required at the ends of the brasses, these can be turned on the mandrel whi!e making same.

" The metal can now be poured into each brIASS from the top, as will be seen from the second diagram, until it is tin to the level of the top of the brass. When it is sufficiently cool, the mandrel can be withdrawn by means of the handle, leaving a perfect relined bearing provided with the correct radii where required.

"This system is applicable to both new and old brasses, and removes all the difileulty which is sometimes experienced with the oil-boles which are provided in them. These usually have to be stopped up

with fire-clay or some other material, which often causes spitting of the metal and other troubles.

"When once the mould is made, it can be taken care of and used as many times as is required, providing that similar bearings are to he relined. I would draw attention to the fact that it is necessary to clean the brasses well, and to i e-tin them before running the metal in. It may also be found advisable to warm them up slightly."

A Simple Method of Making Piston Rings.

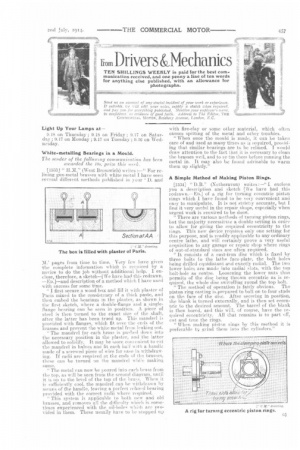

1.1534] "1).B.' (Netheravon) writes;—" I enclose you a description and sketch l_We have had this redrawn.—En.] of a rig for turning eccentric piston rings which I have found to be very convenient and easy to manipulate. it is not strictly accurate, but I find it very useful in the repair shops, especially when urgent work is recuired to be done.

" There are various methods of turning piston rings, lint the majority necessitale a double setting in order to allow for giving the required eccentricity to the tings. This new device requires only one setting for this purpose, and is readily applicable to any ordinary centre lathe, and will certainly prove a very useful acquisition to any garage or repair shop where rings of out-of-standard sizes are often required.

" It consists of a cast-iron disc which is fixed by three bolts to the lathe face-plate, the bolt holes being drilled equidistant and exactly radial. The two lower holes are made into radial slots, with the top bolt-hole as centre. Loosening the lower nuts thus permits of the disc being thrown eccentric as is required, the whole disc swivelling round the top bolt. "The method of operation is fairly obvious. The piston ring casting is_prepared to bolt on to four studs on the face of the disc. After securing in position, the blank is turned externally, and is then set eccentric to the desired amount. The barrel of the blank is then bored, and this will, of course, have the required eccentricity. All that remains is to part off, cut and true the rings. " When making piston rings by tis method it i h s preferable t; grind them into the cylinders."