Cumbria is a rugged, remote part of the British Isles—for

Page 40

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

local hauliers, coping with adverse conditions is all part of a day's work. Paul Newman, Steve McQueen and David

Taylor spoke to six of them and

found that haulage is doing OK along the borders, serving sectors as diverse as agriculture, heavy industry and construction.

Pictures by Andy Forman.

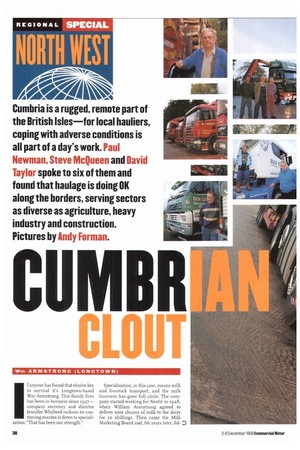

Wm ARMSTRONG (LONGTOWN)

f anyone has found that elusive key to survival its Longtown-based Wm Armstrong. This family firm has been in business since 1927— company secretary and director Jennifer VI/hyberd reckons its continuing success is down to specialisation: "That has been our strength." Specialisation, in this case, means milk and livestock transport, and the milk business has gone full circle. The company started working for Nestle in 1928, when William Armstrong agreed to deliver nine churns of milk to the dairy for in shillings. Then came the Milk Marketing Board and, 66 years later, fol 0 lowing deregulation Armstrong once again found itself working for Nestle as the food conglomerate signed up local farmers and needed milk haulage expertise.

In 1928 the milk run was handled by a Model T Ford. Today Armstrong's tanker fleet comprises 14 six-wheel rigids and three artics, all fitted with Diessel on-board metering equipment at a cost of L25,000 a vehicle.

The artics in the milk fleet are Volvo FLios and Blacicwater-built 21,000-litre twin-axle rear-steer trailers. These rigs cost iiio,000 apiece. "The capital outlay at the time for us was enormous," says Whyberd. "We had to take risks but we have come through well."

The company collects from farms in Cumbria and south-west Scotland for Nestle's Dalston processing plant. During the autumn breeding-stock sales, Armstrong's fleet of 20 livestock wagons works flat out. "We carry about two-million sheep a year," says Whyberd, "mostly lambs born in the spring moving down for breeding, for further fattening or to the abattoirs."

The company also takes breeding pigs to the Continent in specially designed trailers equipped with on-board watering facilities and resting room.

Most of the livestock carriers are Scanias but they've proved to be somewhat over-specced. "We bought 144s and have had problems with them because they're too fancy," says Whyberd. "We've now got a couple of Daf38os which are going well. In the livestock fleet drivers don't have their own vehicles—we have to keep the vehicles working and

606 ARMSTRONG keep the animals moving."

Being just off Junction 44 of the MG means the company is well placed as a staging point for • Scotland, so Armstrong runs 16 curtainsiders on a subcontract for Wincanton Distribution making deliveries into Scotland. Loads are trunked up to the Armstrong yard and then broken for delivery.

Wm Armstrong is very much a family business. There were four brothers, Robert, Jock, Harold and Cyril Harold and Jock died in 1984, followed by William Armstrong senior the same year.

Now the company, which employs about 90 staff including 70 drivers, is run by Robert as chairman with his brother Cyril as a director. William Armstrong junior, Jennifer's brother, and cousins Derek and Geoffrey represent the third generation. They're all very much hands-on and split the work between them. Derek takes care of the livestock. Geoffrey and Cyril look after the Continental work, specialist breeding-stock pigs, and general haulage, while William looks after the workshop and maintenance of the fleet.

"Our strength is the family," says Whyberd. "I'm not saying we don't have our difficulties, but we can sort things out by regularly talking to one and other."

FACTFILE Wm Armstrong

BASED: Longtown, Cumbria.

FOUNDED: 1927, Newtown, Cumbria.

CONTACT: Derek Armstrong (livestock);

Geoffrey or Cyril Armstrong (general haulage).

REET: 56 vehicles including Scanias,

Volvos and Dafs. Buys new and second-hand. Most recent purchase: Dar FTEI5CF, August 1999.

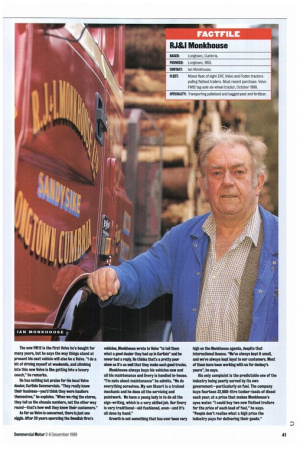

SPECIALITY: Livestock and milk. R4.1861 MONKHOUSE For an international haulier, RJ&I Monkhouse is remarkably unadventurous. It's a small family firm, founded in 1950, running eight trucks and hauling mainly fertilizer and building materials. Located in Longtown, just a stone's throw from Gretna, the company does nearly all Its business within a small catchment area south of the border, in the rural districts of Cumbria.

In fact RJ&I Monkhouse is not really an International haulier, though it boasts an international Operator's Licence. That is a vestige, perhaps, of some long-forgotten ambition of the founder.

His son, Ian, who now runs the family business, explains: "When 0-licences came In loan remember my father saying 'we might as well have an International one'." Despite this, the firm has seldom even ventured across the border into Scotland, let alone sailed across the Channel to the Continent. "We've always relied heavily on local industry, and the bulk of our work is south of the border," Monkhouse explains. For anybody unfamiliar with Cumbria, that means the company serves the agricultural industry.

With the exception of Carlisle, a few miles to the south, there is little within Monkhouse's catchment area that is not rural. The company headquarters is about as pastoral as you could get: set deep in a wood overlooking the Solway Firth.

About 75% of the firm's business Involves hauling peat and fertilizer. All the trailers are flatbeds; the goods are all either palletised or carried In half-tonne bags,

The type of work they do dictates the specification of the vehicles. As they frequently have to manoeuvre in farm yards and other soft and slippery surfaces, Monkhouse opts for tag-axle six-wheel tractive units which can adapt to difficult ground conditions by lifting or lowering the rear axle. Besides carrying peat and fertilizer, Monkhouse also hauls structural steel and timber.

At present, Monkhouse runs a mixture of Volvo, ERF and Foden tractors and has just added a Volvo FM12 to his fleet. "I did consider switching completely to ERF at one time, but I had problems with the first one so I had second thoughts," he says. However, he did buy two more. "We didn't have so many problems with those, but they were still a bit troublesome," he reports.

The new FM12 is the first Volvo he's bought for many years, but he says the way things stand at present his next vehicle will also be a Volvo. "I do a bit of driving myself at weekends, and climbing into this new Volvo is like getting into a luxury coach," he remarks.

He has nothing but praise for his local Volvo dealer, Carlisle Commercials. "They really know their business—you'd think they were hauliers themselves," he explains. "When we ring the stores, they tell us the chassis numbers, not the other way round—that's how well they know their customers."

As far as Volvo Is concerned, there Is Just one niggle. After 20 years operating the Swedish firm's vehicles, Monkhouse wrote to Volvo "to tell them what a good dealer they had up In Carlisle" and he never had a reply. He thinks that's a pretty poor show sag's as well that they make such good trucks.

Monkhouse always buys his vehicles new and all his maintenance and livery is handled in-house. "I'm nuts about maintenance" he admits. "We do everything ourselves. My son Stuart is a trained mechanic and he does all the servicing and paintwork. We have a young lady into do all the sign-writing, which is a very skilled job. Our livery is very traditional—old fashioned, even—and it's all done by hand."

Growth is not something that has over been very high on the Monkhouse agenda, despite that International licence. "We've always kept It small, and we've always kept loyal to our customers. Most of them have been working with us for donkey's years", he says.

His only complaint is the predictable one of the industry being poorly served by its own government—particularly on fuel. The company buys fourteen 32,600-litre tanker-loads of diesel each year, at a price that makes Monkhouse's eyes water. "I could buy two new flatbed trailers for the price of each load of fuel," he says. "People don't realise what a high price the industry pays for delivering their goods."

FACTFILE RJ&I Monkhouse

BASED: Longtown, Cumbria.

FOUNDED: Longtown, 1950.

CONTACT: Ian Monkhouse.

FLEET: Mixed fleet of eight ERF. Volvo and Foden tractors puffing flatbed trailers. Most recent purchase: Volvo FM12 tag-axle six-wheel tractor, October 1999.

SPECIALITY: Transporting palletised and bagged peat and fertilizer.

B&S TRANSPORT

n any operators get started because a local product requires transport out of their area, then they begin looking for a load back. B&S Transport started out with loads in

to the area and then started to look for eco

nomical ways to get out to them. Paul Stables was a partner when the business was set up in 1985 with a single artic tipper that was doubleshifted round the clock. Now there are four vehicles in the fleet.

"We knew the owner of a wood residue business and he was just starting to develop his business at the time we were trying to develop ours—we came in at the right time," says proprietor Paul Stables. The job involved bringing in chippings and other wood residue from the Scottish forests for processing in local building material factories. The inward loads are still wood based, but the applications are much wider. For example, these days B&S brings down stripped bark, which is processed and sold in garden centres.

If the object of an efficient haulage exercise is to build a business based on round-trips that incur the minimum amount of empty mileage, then B&S is doing pretty well. "We originally set up with tipping trailers, but when you are carrying shavings and chippings you really need the volume," Stables explains. "When we switched to curtainsiders they gave us the opportunity to increase the volume and the chance to load with plasterboard out of the British Gypsum factory at Kirkby Thor. That gave us better distribution throughout Scotland and enabled us to get to the places where we wanted to be."

The Scottish destinations he needs are Thurso, (Than, Aberdeen and Inverness, where his regular return work originates. From these sites he can bring back wood products to manufacturing plants less than 10 miles away from base, before calling in at Kirkby Thor a couple of miles down the road for another outward trip.

Drivers working for B&S can expect to be on a night out two or three times a week. Stables himself still drives, but tends to concentrate on the runs to the North-East so he can get back quickly to keep the business running smoothly. This is helped by the 24hour loading capabilities at the British Gypsum plant, no doubt reacting to the fact that builder's merchants are less inclined to hold large stocks these days. According to Stables, more and more of the deliveries are being scheduled.

This makes the efficiency of the operation all the more important, and this relies in part on the flexibility of the equipment employed. The company's curtainsiders are equipped with extra-strong curtains in order to cope with the different types of loads involved. The wood products are loaded through an aperture in the roof and rely on the strength of the curtains for load security. The plasterboard from British Gypsum is loaded and unloaded conventionally through the sides.

Stables became the sole proprietor of the business in 1994; he now runs it with his wife Janice. It is a business that has remained solid despite the upheaval caused by the dissolving of the original two-man partnership in 1994 and the financial implications of the split. He puts that down to careful financial management of a fleet chosen for its fuel efficiency—and the good fortune to be a haulier working in two business sectors that appear to match each other perfectly.

FACTIFILE B&S Transport

BASED: Appleby, Cumbria.

FOUNDED: March 1985, CONTACT: Paul and Janice Stables.

FLEET: Four artcs—M-B Actros 1840 4x2, Scania 124.360

4x2, Soma 124 (converted 6x2), Foden Alpha 6x2. Buys new. Most recent purchase: 1999 Foden Alpha.

SPECIALITY: Wood residue, building products. iNhen John Pattinson was six months old his father died in a road accident while driving one of his father-in-law's trucks. The tragedy could so easily have meant the end of the family haulage business, Ben Sayer Westmorland. With no sons of his own, the company founder, Ben Sayer, had expected to pass the business on to his son-in-law. That the business carried on is testimony to the determination of John Pattinson's mother and aunt, who together took over the running of the business when Sayer eventually died in the late 1960s.

John Pattinson was then 11 years old. On leaving school he trained as a mechanic before joining the family firm which he now runs.

The company has changed little over the years. It is still family-run, still small, with only five vehicles, and still serving much the same client-base as it did when it was established in 1936, Pattinsan's grandfather started out hauling granite from Shap quarry, now owned by concrete and aggregates giant RMC. It's still Ben Sayer Westmorland's biggest single customer, but it's far from being the company's only customer.

From its depot on the A66 trans-Pennine route at Brough, high up on the fells above Kirkby Stephen, the company hauls aggregates, coal, grain and other bulk products throughout the North-East.

"All our vehicles are bulk tippers," says Pattinson, "Besides granite we do a lot of coal, which is a line my grandfather started many years ago."

All but one of his vehicles are 21-tonne eight-wheel rigids. Artics might have the edge in terms of payload (typically carrying 26 tonnes), but Pattinson is happy to stick with his rigids.

'There aren't many eight-wheeler rigid tippers around. But we load household coal, and the domestic merchants often have small yards which the larger wagons can't get into so easily," he explains. "So we stick with the rigids, and our customers stick with us," Besides coal, the company hauls grain from the docks at Teesside over the Pennines to mills in Penrith. Occasionally it handles farm produce, such as turnips and fodder beet. Pattinson describes his customer base as "small but loyal", and that's the way he likes it.

Pattinson has never felt tempted to expand the business, reasoning that the bigger the business is. the harder it is to manage. Besides himself, Pattinson employs four full-time drivers and a couple of part-timers, His wife Helen is company secretary and looks after all the administrative work.

Although the fleet is small, Ben Sayer Westmorland has a large, well-equipped workshop and carries out all its own routine maintenance and repairs. 'It's a good big garage," he says. "I dare say we could do maintenance work for other hauliers, but I think that way of life is dying fast. People don't want to be bothered these days. They lease for three years and all the maintenance is thrown in." The company buys new and second-hand vehicles. The fleet currently comprises four Volvo rigids—three F110s and a new FM12, bought in October—with a Scan is 113-360 artic, Pattinson's son Alan, 20, is a trained mechanic and a driver too. He qualified via the Young Drivers' Scheme and was only the 17th applicant in the UK to qualify this way, "We're very proud of him," says Pattinson. "The paperwork was unbelievable, but he's got his Class C, so now he can drive the eight-wheel rigids.

Like just about every other haulier in the country, Pattinson is bitter about the way the industry is being treated. He was one of a coachload of people from the region who travelled to London last summer to demonstrate for fair treatment. But although he felt it was worth the effort, he doubts that demos will change anything. "There's one way we could sort it out, though," he says, "and that's to stay at home for a fortnight. The whole country would grind to a standstill."

FACTIFILE

Ben Sayer Westmorland

BASED: Brough, near Kirkby Stephen, Cumbria.

FOUNDED: Brough, 1936.

CONTACT: John Pattinson, FLEET: Three Volvo F1.10 and one FM12 eight-wheel rigid tippers; one Scania 113 articulated tipper. Most recent purchase: Volvo FM12, October 1999. Buys new and second-hand SPECIALITY: Bulk haulage, mainly aggregates and coat

HELP FOR HAULIERS

Hauliers across Cumbria may be entitled to financial assistance and advice from several sources.

Business Link Cumbria can offer sound business advice; Enterprise Cumbria can provide financial help— for example to cover a firm's train ing and recruttment needs.

Assistance could also be available from the European Social Fund, which in some circumstances can pay up to 45% of a business's training costs, The European Regional Develop ment Fund is also on hand to help those in the private sector—with this body, assistance is generally intended for companies in the manufacturing sector, although in some cases those in the haulage industry could be eligible. Contacts: Business Link Cumbria: 01900 700110. Enterprise Cumbria: 01900 700050, European Social Rind information: 0131 2440731.

European Regional Development Fund information: I1131 244 0715. RJ MURRAY & SON

Mrith a major peat bog and processing plant on the doorstep, and sitting on the main England/Scotland arterial, RJ Murray & Son is well placed to carve out a living in sparsely populated Cumbria. We are quite lucky that we are at the gateway to Scotland," says Stephen Murray, general manager of the Longtown-based general haulier. "It does tend to be the main route up into Scotland even from the east. People come across the A66 and up the A74 because the Ai up the east isn't the best of roads, so we do get a lot of through traffic."

It's that through traffic that has led to the company's latest venture. Murray offers a mini woupage service into central Scotland in return for bacldoads of palletised peat from its depot and store. Contacts are gleaned from the more than 400 hauliers the company has worked with. "Some of them are going past our front door with six pallets on because they have been delivering all the way up the country," Murray explains. "We can put those with other people's pallets that have been dropped in and we'll make a full load for delivery into central Scotland. They can load the peat on for us and they are then a day ahead of themselves."

So far Murray is working with six regulars but

he says another 20 are interested in joining the scheme. And the company's soon-to-belaunched web site will offer the service to

hauliers throughout the UK.

It's one way of exploiting the proximity of the border. "It's a funny thing but it seems to be a big wall to some people, says Murray. "They don't like crossing it" Murray's grandfather started the business between the wars in a house a couple of miles from the company's current site. Then the work was primarily in the livestock industry, running rigids. The business was taken over by his parents in the 1960s and moved to its current site at Longtown in the late 1970s. First they took over one of three disused airforce storage buildings, and then gradually acquired the whole site. Now the company has bought an adjoining field which takes the depot up to 30 acres. This is mainly used for storage of up to 25,o0o pallets of peat, which will rise when the new field is developed.

For nearly 20 years Murray has been running a peat distribution operation from its depot. The peat is treated, mixed and packed at a nearby factory situated on the bog. The palletised loads are delivered to Murray's depot for storage; from here it also handles all the collating and booking-in for the factory, puts the loads together and handles the distribution.

It's a large and complicated operation which dominates the haulier's business. "People tend to say that we have got all our eggs in one basket—but if you have a chance of something like that, you make sure that you do it right and you keep it," says Murray.

He's proud that this is still a family-run company. As a tribute to his grandfather, who fought in tanks and was awarded the Military Medal and Bar in the First World War, all the vehicles are named after British tanks. "We got in contact with the British Tank Museum at Bovington who faxed us up an updated list because when we went from a dozen vehicles to 23 we ran out of names," says Murray.

distribution.

FACTFILE RJ Murray & Son

BASED: Longtown, Cumbria.

FOUNDED: 1930s, Longtown.

CONTACT: Stephen Murray.

FLEET: 32 tractors, mostly

Scanias, with a couple of ERFs and an Iveco; 40 trailers, mostly curtainsjders with five flats. Buys new. Most recent purchases: Two Scania 124 420 6x2 twin-steers and an !yen° EuroStar 380.

SPECIALITY: Peat storage and

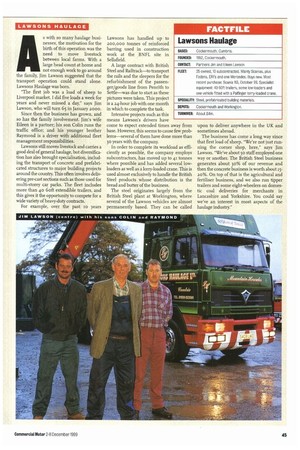

LAWSONS HAULAGE

As with so many haulage businesses, the motivation for the birth of this operation was the need to move livestock between local farms. With a large head count at home and not enough work to go around the family, Jim Lawson suggested that the transport operation could stand alone. Lawsons Haulage was born..

"The first job was a load of sheep to Liverpool market. I did five loads a week for years and never missed a day," says Jim Lawson, who will turn 65 in January 2000.

Since then the business has grown, and so has the family involvement. Jim's wife Eileen is a partner; his son Colin runs the traffic office; and his younger brother Raymond is a driver with additional fleet management responsibilities.

Lawsons still moves livestock and carries a good deal of general haulage, but diversification has also brought specialisation, including the transport of concrete and prefabricated structures to major building projects around the country. This often involves delivering pre-cast sections such as those used for multi-storey car parks. The fleet includes more than 40 6oft extendible trailers, and this gives it the opportunity to compete for a wide variety of heavy-duty contracts.

For example, over the past ro years Lawsons has handled up to 200,000 tonnes of reinforced barring used in construction work at the BNFL site in Sellafield.

A large contract with British Steel and Railtrack—to transport the rails and the sleepers for the refurbishment of the passenger/goods line from Penrith to Settle—was due to start as these pictures were taken. This project is a a4-hour job with one month in which to complete the task.

Intensive projects such as this means Lawson's drivers have come to expect extended times away from base. However, this seems to cause few problems—several of them have done more than 30 years with the company.

In order to complete its workload as efficiently as possible, the company employs subcontractors, has moved up to 41 tonnes where possible and has added several lowloaders as well as a lorry-loaded crane. This is used almost exclusively to handle the British Steel products whose distribution is the bread and butter of the business.

The steel originates largely from the British Steel plant at Workington, where several of the Lawson vehicles are almost permanently based. They can be called upon to deliver anywhere in the UK and sometimes abroad.

The business has come a long way since that first load of sheep. "We're not just running the corner shop, here," says Jim Lawson. "We've about 50 staff employed one way or another. The British Steel business generates about 3o% of our revenue and then the concrete business is worth about i20%. On top of that is the agricultural and fertiliser business, and we also run tipper trailers and some eight-wheelers on domestic coal deliveries for merchants in Lancashire and Yorkshire. You could say we've an interest in most aspects of the haulage industry."

FACTFILE Lawsons Haulage

BASED; Cockermouth, Cumbria.

FOUNDED: 1952, Cockermouth.

CONTACT: Partners Jim and Eileen Lawson FLEET: 25 owned, 10 subcontracted. Mainly Scanias, plus

Fodens. ERFs and one Mercedes. Buys new. Most recent purchase: Scania 113, October 99. Specialist equipment: 40 60ft trailers, some low-loaders and one vehicle Fitted with a Palfinger lorry-loaded crane.

SPECIALITY: Steel, prefabricated building materials.

DEPOTS: Cockermouth and Workington.

TURNOVER: About £4m.