WORKSHOP BRAN I PARTS

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

• Extensive, international, original equipment business provides the basis for the Lucas Girling replacement brake parts range. This is now being supported by a comprehensive all-makes programme, says the company, which covers all aspects of the braking system including both hydraulic and air-actuated foundation brakes as well as hydraulic actuation system components and brake service tools.

The reliability of the guaranteed Lucas Girling product is under-pinned by original equipment design, development and production commitment. Every part, from shoe return springs to complete foundation brakes, meets the same stringent standards as the equipment fitted originally by the vehicle manufacturer.

This is not always the case with many components available in the service market. The Lucas Girling range is made widely available to vehicle operators through the extensive distributor network which covers the UK and is augmented by the company's own team of field service engineers.

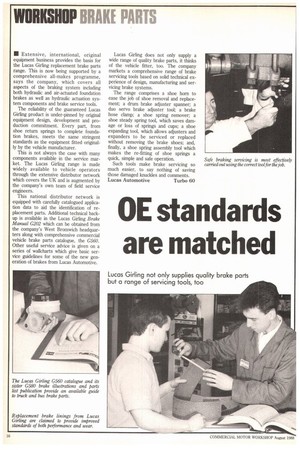

This national distributor network is equipped with carefully catalogued application data to aid the identification of replacement parts. Additional technical backup is available in the Lucas Girling Brake Manual G202 which can be obtained from the company's West Bromwich headquarters along with comprehensive commercial vehicle brake parts catalogue, the G560. Other useful service advice is given on a series of wallcharts which give basic service guidelines for some of the new generation of brakes from Lucas Automotive. Lucas Girling does not only supply a wide range of quality brake parts, it thinks of the vehicle fitter, too. The company markets a comprehensive range of brake servicing tools based on solid technical experience of design, manufacturing and servicing brake systems.

The range comprises a shoe horn to ease the job of shoe removal and replacement; a drum brake adjuster spanner; a duo servo brake adjuster tool; a brake hose clamp; a shoe spring remover, a shoe steady spring tool, which saves damage or loss of springs and cups; a shoe expanding tool, which allows adjusters and expanders to be serviced or replaced without removing the brake shoes; and, finally, a shoe spring assembly tool which makes the re-fitting of shoe springs a quick, simple and safe operation.

Such tools make brake servicing so much easier, to say nothing of saving those damaged knuckles and comments.

Lucas Automotive Turbo 60