Volvo consolidates its US market bridgehead

Page 55

Page 56

Page 57

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

IT WAS probably just coincidence that while a large party of British commercial vehicle journalists were in Sweden for the launch of the new 10 and 12 litre GA engine variants in 1981, Volvo also announced its purchase of the ailing American manufacturer, White Motor Corporation.

Whatever the circumstances, it gave reporters plenty of opportunity to speculate on the likely effects of the US company takeover, although the more imaginative predictions of a mass exodus across the Atlantic of F10 and F12 tractive units 'spearheading a European invasion' have proved to be little more than flights of fancy.

The acquisition of White's assets (basically its manufacturing plants and most of its distributor network) allowed Volvo not only to enter the prestigious US class eight heavy-duty tractive unit market with the existing White range, but also to build its own vehicles in the United States for the first time.

But why should the US market be so attractive to European manufacturers such as Volvo, Mercedes and Renault? The answer is quite simply numbers. The United States is the world's single largest truck market with normal cv sales roughly equal to the combined sales of Western Europe.

With 1984 sales of class eight tractive units (36 tonnes gcw) alone expected to be more than 120,000 units the potential of the American market, despite the recent recession, cannot be ignored by truck manufacturers like Volvo, whose livelihood depends on world sales. Last year the company sold a total of 2,456 vehicles of all types in its home market.

Volvo however is no newcomer to the US commercial vehicle market. Swedish-built units have been sold in America since 1975, while operational field tests with US fleets began as far back as 1970.

The original purchase philosophy and present Volvo White company structure have already been more than adequately covered in Commercial Motor by CM engineering editor Tim Blakemore, who recently visited Volvo White's Ogden (Utah) plant where Autocar conventional (bonneted) class eight tractive units are produced along with heavy offroad construction vehicles (CM Feb 4, 1984).

By far the largest part of Volvo White Truck Corporation's manufacturing operations, however, take place 1,700 miles to the east of Ogden at New River Valley in Dublin, Virginia.

Situated 2,080ft above sea level on top of the Christianburg plateau in the heart of the famous Blue Ridge Mountains, the 550,000sq ft New River Valley plant lies next to the important north-south trunk route of Interstate 81. Built originally by White in 1974, NRV is one of the more modern assembly facilities in the USA, and is little more than an hour's drive from Volvo White Truck Corporation's Greensboro Headquarters in the neighbouring state of North Carolina.

Perhaps the most impressive aspect of NRV's production is the variety of vehicles built on the same 1,400ft assembly line. Up to 50 vehicles can be built in a day at NRV although production rates can be varied according to the models, componentry and type of truck produced.

White models consist primarily of class eight cab-over-engine (CUE) and conventional (bonneted) 4x2 and 6x4 tractive units built as sleeper or day cab models. Like many US trucks, the White tractors use a great deal of aluminium in their construction to reduce weight.

In addition, NRV builds the 4x2 and 6x4 rigid White Xpeditor range which is intended for the US municipal market, where it currently holds a 35 per cent share.

All White models can be specified with the usual range of American proprietary engines — Cummins, Detroit Diesel and Caterpillar. The most popular unit for 6x4 tractive unit operation is the Cummins engine rated between 300-400bhp. New River Valley and Ogden are the only two Volvo plants in the world where other manufacturers' engines are fitted on the normal production line.

As well as White badged models, NRV also builds a limited number of Autocar K models usually for specialised operations.

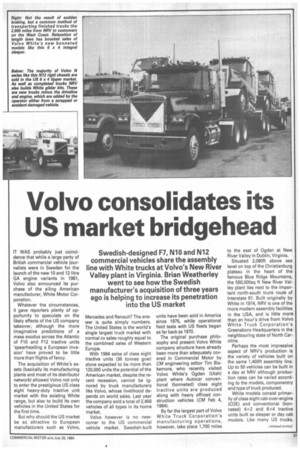

Walking along the assembly line at New River Valley, visitors are quickly reminded of the Swedish connection. In between the multi-coloured high COE and bonneted US tractors are familiar European F7, N10 and N12 units. For the US market the F7 is built as a 4x2 and 6x4 rigid for class eight operation and as a 4x2 tractor powered by the 7 litre TD 70F charge cooled engine for the class seven (27.21 tonnes gcw) haulage sector where it has been selling well particularly among short-haul own-account operators.

Bonneted N range models have been assembled at New River Valley since 1982. The N10 and N12 are designed to operate in the US class eight sector, and are available as either 6x4 day cabbed rigids or tractive units. However, the majority are built as 6x4 tipper chassis (there being no eight-wheel tipping market to speak of in the USA). These are sold in competition with the market leaders Mack, which, like Volvo, is one of the few cv manufacturers producing its own axle, gearbox, engine drive-line package in-house.

Volvo's attack on this particular sector was stepped up earlier this year with the introduction in March of the N12 powered by Volvo's 12 litre charge-cooled engine.

Eight variants of the N12 Intercooler are sold in the US comprising four tractive units and four tipper chassis. Designed for heavy duty operation in the construction and fuel oil industries as well as normal on .highway operation, the N12 tipper is plated from 24.49-31.86 tonnes gvw while tractive units are plated for 36.28-49.89 tonnes gvw operation. Horsepower ratings on the 12 litre engine can be either 212kW (285bhp) or 242kW (325bhp) depending on the individual chassis type.

As well as assembling the F7 and N series models using Swedish-supplied components and some local content such as tyres and batteries, Volvo White also imports completely built-up (cbu) F6 4x2 rigids. Powered by the turbocharged TD60 engines, these are produced at Volvo's Belgian Ghent plant.

The addition of the F6 enables Volvo White to field an impressive US range of Swedish-designed vehicles with gvw's from 12-36 tonnes, powered by en gines rated from 130-242kW (174-325bhp) — more than any other European cv manufacturer currently selling in the US.

The building of Volvo trucks is very much a secondary operation at NRV. Its main task is producing White tractive units. Of the 37 vehicles produced per day at NRV, 32 on average are White models. Last year White and Autocar achieved sales of 4,650 units in the class eight sector — a figure, which although small compared to IH and Mack, is steadily growing.

Before walking round the plant I spoke to Sam Levy, NRV's industrial relations manager, who explained the philosophy behind White's manufacturing operations and, in particular, the relationship between the local workforce and the new Swedishowned company.

Unlike the majority of European 'integrated' tractive units, US class eight vehicles are still very much 'component' trucks individually tailored to the operators need, not only in terms of driveline specification, but right down to how many small marker lights are put on the cab roof.

In a large scale assembly operation too much product diversity can cause enormous production problems, but for smaller manufacturers such as White, it can be a positive benefit. Sam Levy explained: "US trucks are still individually tailored, and that requires a far greater product specialisation on the part of the workforce, but with each job being different, quality increases because people are not doing a repetitive building job."

The best way to appreciate the American philosophy of on-line customer options is to stand alongside the White assembly line. Items such as extra fuel tanks, alloy wheels, air-operated fifth wheels, air starters, even an unusual rocking beam suspension unit on a 6 x 4 tractive unit rear bogie, were all being fitted on vehicles I saw on the NRV line.

White can also supply tractive units painted in any style from a single two-colour livery for large fleet operators up to intricate multi-coloured paint finishes for an owner operator. As a result of tackling any paint job, White has a "cab paint-chip count" according to Sam Levy of more than 35,000 individual colours. The only exception to the NRV rule is the Volvo units which are built with the standard Swedishsupplied white painted cabs.

Many European manufacturers — Volvo Gothenburg in cluded — might well shake their heads at NRV's highly individual production techniques, but Sam Levy sees no immediate change in US truck operators' lightweight highly customised buying habits. "Nineteen eighty four has not seen any backing off in demand for customised machinery — it would be unheard of."

Volvo White has recently introduced new models in its White tractive unit range with new high COE and bonneted models following the old Road Commander and Road Boss variants. White is unique in the US as the only US manufacturer to offer an integral sleeper cab on its class eight 6x4 bonneted truck. Unlike normal conventional sleepers which have a separate sleeper box fitted behind the long wheelbase day cab, White's bonneted integral sleeper is based on the same cab used on its high COE models, similar to Scania's GPR and T range. The advantages of this system are obvious, particularly in reduced truck cab production costs, for Whites overall range.

Much attention has also been paid to the aerodynamic performance of both models. The integral sleeper fitted with a roof deflector achieves a 0.633 coefficient and the high cab-over model scored a 0.60 wind aver

aged drag coefficient in tests carried out at the University of Maryland.

Cab ride — often the biggest criticism in American tractive units — has also been revised on the White range. Air-bag cab mounts are fitted as standard on the bonneted integral sleeper. Instrumentation in both models however, is still some way be hind European vehicles, with in tenor layouts haphazard and cramped in comparison with the NRV-built Volvos.

Despite predictions to the contrary, it soon became clear after 1981 that Volvo would not be making major engineering changes to NRV products by introducing Swedish driveline components into the White truck range. Even accepting American operators' natural conservatism, as witnessed by their preference for bolted frames and constant mesh gearboxes, few understanderbly would take any foreign manufacturer's word that his untried product was superior to a proven US vehicle. Vertical integration, then, is likely to be a slow process, although there is "very intensive engineering development work" currently taking place between Gothenberg and the US, according to Sam Levy.

But one small example of Swedish influence in NRV can be found in the high COE tractive unit that uses a short Volvo-type gear lever replacing an imprecise long-lever unit that was causing gear change problems on a large fleet order.

Further, the change in vehicle length laws since de-regulation in 1978 and the Surface Transport Assistance Act of 1982, has meant that the cramped COE interior can now be improved, probably with some help from Sweden.

White Trucks is unlikely to re duce significantly its large list of customer options, although economic pressures have already seen a decline in the numbers of 298 kW (400hp) plus engines specified. "When diesel was 30 cents (42 pence) per gallon it didn't make much difference; now it's a dollar twenty it is a disadvantage — we've seen the last of the big fuel hogs."

While new products are relatively simple to integrate, gaining the confidence of a workforce is not so easy. How then had the NRV Virginians reacted to the Swedish takeover in 1981? The existing good reputation of Volvo's cars in the US played a significant part, according to Sam Levy.

"When they heard they were going to build Volvo trucks, the workforce was very enthusiastic. Since 1981 we've increased the total NRV workforce from 600 to the present 1,000 and our absenteeism rate of seven tenths of one per cent is the lowest rate of any truck manufacturing plant in the US."

When Volvo purchased White some of its dealers were discontinued, but over 75 per cent — the "spine of the old network" — opted to join the new company which now has 220. The committment to new products from dealers is emphasised by the fact that 1984 N12 production is already sold out.

As each truck comes off the NRV line it undergoes a 30 minute road test programme, and trucks are regularly pulled off the line at random for a complete quality control inspection. The product flexibility achieved by Volvo White at New River Valley was amplified by quality control manager, Joe Walker. Compared to larger manufacturers like IH or GM, NRV's relatively low production levels allow it to tackle all of the specialised one-off vehicles that bigger manufacturers turn away. As a result White has gained a reputation among operators for highly specialised vehicles.

A more unusual example standing in the NRV compound was a short-wheelbase Autocar K model 4x2 rigid fitted with a steering rear axle intended for use as an airport aircraft refueller.

Left-hand drive Volvo models built at NRV have few differences from the units built at Gothenburg. Cab interior changes account for the majority. Speedometers sit in place of tachographs and the normal floor-mounted handletype park brake is replaced by the standard US dash-mounted push-pull knob controlling tractor and trailer park brakes. Although retaining two line braking, US tractive unit models also have an additional 'deadman's handle' acting solely on the trailer.

Exterior modifications include US style mirrors, vertical exhausts and the option of Trilex wheels.

In spite of its obvious Swedish connection, there is no doubt as to Volvo White's autonomy in the US. During my visit to NRV there were only five Swedes working at the plant — one of whom was there for the specific purpose of my visit.

Along with the resurgence of White's new models, NRV-built Volvo trucks are now firmly established in the class seven and eight sectors of the US truck market and the launch in the market of the N12 Intercooler has, according to Volvo White's president, Thage Berggren, "completed an extensive product investment phase begun immediately after the creation of Volvo White."

Whether future investment programmes will lead to greater integration of Volvo and White models in the US remains a subject for speculation.