A Remarkable Six-wheeler Conversion

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

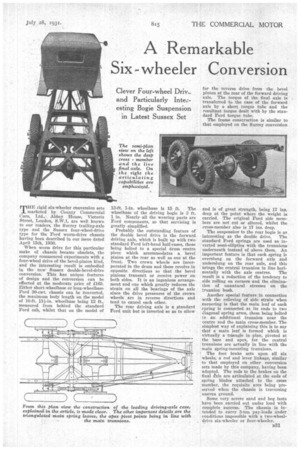

THE rigid six-wheeler ennversion sets marketed by County Commercial Cars, Ltd., Abbey House, Victoria Street, London, S.W.1, are well known to our readers, the Surrey trailing-axle type and the Sussex four-wheel-drive type for the Ford worm-drive chassis having been described in our issue dated April 15th, 1930.

When worm drive for this particular make of chassis became obsolete, the company commenced experiments with a four-wheel drive of the bevel-pinion kind, and the interesting result is embodied in the new Sussex double-bevel-drive conversion. This has unique features of design and the conversion can be effected at the moderate price of .f105. Either short-wheelbase or long-wheelbase Ford 30-cwt. chassis can be converted, the maximum body length on the model of 10-ft. wheelbase being 12 ft., measured from behind the standard Ford cab, whilst that on the model of 13-ft. 1-in, wheelbase is 15 ft. The wheelbase of the driving bogie is 3 ft. 1 in. Nearly all the wearing parts are Ford components, so that servicing is greatly simplified.

Probably the outstanding feature of the double bevel drive is the forward driving axle, which is built up with two standard Ford left-hand half-eases, these being bolted to a special drum centre piece which accommodates a bevel pinion at the rear as well as one at the front. Two crown wheels are incorporated in the drum and these revolve in opposite directions so that the bevel pinions transmit or receive power on both sides. It is an ingenious arrangement and oue which greatly reduces the strain on all the bearings of the axle since the drive pressures of the crown wheels are in reverse directions and tend to cancel each other.

The rear driving axle is a standard Ford unit but is inverted so as to allow

and is of great strength, being 17 ins. deep at the point where the weight is carried. The original Ford side members are not cut or altered, whilst the cross-member also is 17 ins. deep.

The suspension to the rear bogie is as

interesting as the double drive. The standard Ford springs are used as inverted semi-elliptics with the trunnions underneath instead of above them. An important feature is that each spring is overslung on the forward axle and underslung on the rear axle, and this brings the central trunnion in line hori zontally with the axle centres. The result is a reduction of the tendency to side rolling on corners and the elimination of unnatural stresses on the trunnion bush.

Another special feature in connection with the relieving of side strain when cornering is that the main leaf of each rpring is connected at its ends to two t;iagonal spring arms, these being bolted to an additional trunnion near the centre and the main cross-member. The simplest way of explaining this is to say that a main leaf is formed which is virtually a triangle in plan; pivoted at the base and apex, for the central trunnions are actually in line with the main spring-mounting trunnions.

The foot brake acts upon all six wheels, a rod and lever linkage, similar to that employed on other conversion sets made by this company, having been adopted. The rods to the brakes on the final hle are articulated at the ends of spring blades attached to the CFOSS member, the requisite arcs being preserved when the chassis is traversing uneven ground.

Some very severe sand and bog tests have been carried out under load with complete success. The chassis is intended to carry 3-ton payloads under conditions impossible with a two-wheeldrive six-wheeler or four-wheeler.