HINTS ON MAINTENANCE.

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

629.—Removing a Sump Under Difficulties. - Some time ago a big-end bearing had to be replaced on a commercial vehicle witha unit-constructed engine and gearbox. As there were DO side doors in the crankcase it was obviously necessary to remove the sump and the vehicle was driven on to the pit and an apparently straightforward job proceeded with ; but after the bolts, nuts, etc., securing the sump to the crankcase, gearbox flange and timing-case cover had been removed, it was found impossible to drop it in the usual manner, as the timing-case cover was secured by studs instead of set-screws or bolts and nuts.

The sump could not be slid back to draw the studs clear of the cover, as at the rear end it butted against the gearbox, and the cover could not be drawn forward off the studs. as there was only *-in. clearance between it and the front crossmember. The studs also could not be easily removed as they were only in, in diameter, and after removal of the nuts only projected a bare A in. from the cover, so that it was impossible to lock two nuts together to unscrew them.

It seemed that it would be necessary either to remove the gearbox or to unbolt the whole unit from the chassis and sling it clear ; but, as the vehicle was urgently required, a little further consideration was given to the matter, and it was eventually decided that the only hope lay in the removal of the stads.

Eventually the idea was conceived of reftlacing the nuts, riveting the ends of the studs over and unscrewing the nuts by means of a spanner when, as the nuts could not come off the studs, the lastnamed would have to be withdrawn. This idea worked splendidly with the bottom two studs, but the other four were right behind, and close to, the cross-member, and eventually were reached by drilling four 1-in, clearance holes in this member approximately opposite the offending studs, the riveting over being achieved by inserting a length

of i-in. round silver steel ground to a point and pushed through each hole in turn. , Whm the sump was finally replaced, as no setscrew of similar thread could be readily obtained, the nuts were brazed on to the studs and these used as set-screws, thus obviating any trouble when dismantling in the future.

The time taken for this job was six hours.

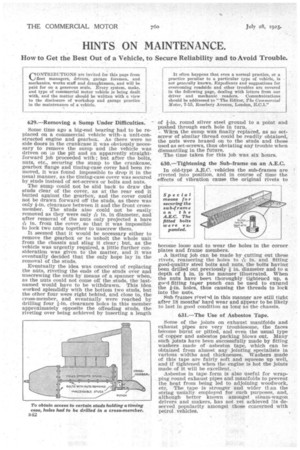

630.—Tightening the Sub-frame on an A.E.C.

In old-type A.E.G. vehicles the sub-frames are riveted into position, and in course of time the effects of vibration cause the original rivets to

become loose and to wear the plates and frame members. holes in the corner A lasting job can be made by cutting out these

rivets, reamering the holes to in. and fitting good-quality steel bolts and nuts, the bolts having been drilled out previously 1 in. diameter and to .a depth of in. in the manner illustrated. When the nuts have been thoroughly tightened up, a good fitting taper punch can be used to expand the j-in. holes, thus causing the threads to lock into the nuts.

Sub frames rhret-kd in this manner are still tight after 18 months' hard wear and appear to be likely to last in good condition as long as the chassis.

631.—The Use of Asbestos Tape.

Some of the joints on exhaust manifolds and exhaust pipes are very troublesome; the faces b&ome burnt or pitted, and even the usual type of copper and asbestos packing blows out. Many such joints have been successfully made by fitting washers made of asbestos tape, which can be obtained from almost any jointing specialists in various widths and thicknesses. Washers made of this tape are fairly soft and squeeze up well, and if tightened when the engine is hot the joints made of it will be excellent.

Asbestos in tape form is also useful for wrapping round exhaust pipes and manifolds to prevent the heat from being led to adjoining woodwork, etc. The tape is stronger and wider flan the string usually employed for such purposes, and, although better known amongst steam-wagon drivers and makers, has not yet Achieved its deserved popularity amongst those ccncerned with petrol vehicles.