THE SCORING OF CYLINDERS: SOME CAUSES.

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

By the Adoption of Gudgeon-pin Retainers, Air Filters and Oil Filters and the Use of Suitable Lubricants, Scoring is Reasonably Preventable.

THE reboring or, better still, the regrinding of a cylinder is a remedy for an evil, but it is a costly means of curing. It renders necessary the fitting of new pistons and rings and, at the same time, throws a vehicle out of work and prevents it from earning money for an appreciable time. When all these Items have been taken into consideration, one may well ask one's self whether it would not have been better. and cheaper to the user had the designers of the engine adopted some form of construction which would have prevented the necessity for this expense to be incurred after a certain period of use.

No part of a machine which is to be subjected to friction and wear will ever be made which will last for ever, but, in the case of a cylinder which requires regrinding, this will not often be found to he due to fair wear and tear. In most of the eases which have come to our notice, the scoring has been due to something which might have been prevented, and it is to these preventable occurrences that we wish to draw attention with a view to their eveidence in the future.

The most common cause of the trouble is, perhaps, a gudgeon pin which has worked out sideways ; next to this, probably, is the presence of some foreign matter in the lubrication, and a third cause is the failure of the lubrication system, either by neglect to provide enough lubricant, a partial or cemnlete stoppage of a ripe, or the use of an inferior or unsuitable oil. Taking these haimenings in their order, let us see what can he done te prevent their occurrence.

A shifting gudgeon pin may be due to several causes, the commonest beingattributable to the off-setting which is sometimes adopted for connecting rods. Connecting rods so designed put a great strain on any device employed for keeping the gudgeon pin in place, as at each stroke there is a tendency for the nin to work sideways. With an evenly disposed eonnecting rod, there should be no bias in either direction ; despite this. however, we have seen a gudgeonpin defeat all efforts to hold it in its proper /dace. Strange as it _may seem, those gudgeon pins which are allowed to revolve in the •niston seem to give the least trouble. The fitting of a scraper

ring which embraces the ends of the pin, although fairly good, is not always a success, as the ring occasionally fails to function correctly. We have seen a gudgeon pin press a ring of this type so hard against the wall of the cylinder that, although there was no distinct groove, the, cylinder showed sufficient wear to call for regrinding.

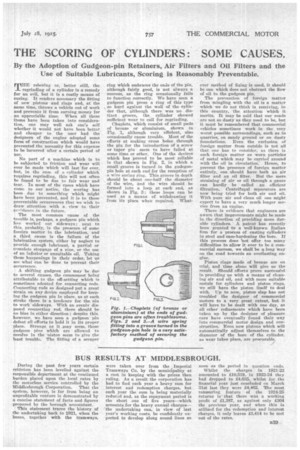

Chaplets, which consist of small pads of bronze or aluminium, shown in Fig. 1, although very, efficient, also oecasionally cause trouble. Most of the efforts at making cross holes through the pin for the introduction of a screw or taper pin seem to have failed at some time or other. One of the devices which has 'proved to be most reliable is that shown in Fig. 2, in which a small groove is turned in the gudegonpin hole at each end for the reception of a wire spring, ring, This groove in depth should be about one-half the diameter of the wire, and the wire should be formed into a loop at each end, as shown in Fig. 3; these loops can be used as a means of withdrawing it from its place when required.. What

ever method of fixing is used, it should be one which does not obstruct the how of oil to the gudgeon pin.

The prevention of foreign matter from mingling with the oil is a matter which we do not think is receiving, in

this country, the attention which it merits. It may he said that our roads

are not so dusty as they used to be, but it must be remembered that commercial vehicles sometimes work in the very worst possible surroundings, such as in quarries, on sandy ground or on dusty foundations. Even the exclusion of foreign matter from outside is not all that one has to consider, as there is such foreign matter as worn particles of metal which may be carried around with the oil in circulation. Hence, to prevent the presence of foreign matter entirely, one should have both an air filter and an oil filter. But the mere straining of air or oil through a ,gauze can hardly be called an efficient filtration. Centrifugal separators are now being tried for both air and oil.

With pure air and clean oil one might expect to have a very much longer service from an engine.

There is evidence that engineers are aware that improvements might be made in the direction of providing more dur able cylinders. A patent has recently been granted to a well-known Italian firm for a process of casting cylinders in steel and case-hardening the bore. If this process does imt offer too many difficulties to allow it ever to he a commercial success, we shall be a long way on the road towards an everlasting engine.

Piston rings made of bronze are on trial, and time idone will give us the result. Should efforts prove successful in providing us with a means of cleaning air and oil, and with more suitable metals for cylinders and piston ringa, we still have the piston itself to deal with. Up to now, piston slap has not troubled the designer of commercial motors to a very great extent, but it will have to be dealt with one day, as all other refinements which have been taken up by the designer of pleasure ears have eventually found their way into commercial motor design and construction: Even now pistons which will automatically adjust themselves to the diameter of the bore of the cylinder. as wear takes place, are procurable.