Mo_ i rcTh„,,, 0,wi r ap by Preceptor

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

THE STEERING BOX on a motor vehicle provides a gear reduction so that the driver can turn the road wheels with a minimum of effort at the steering wheel. The gear ratio employed in the steering box varies from about 10:1 on a light vehicle to 30:1 on a heavy commercial one.

The lower the gear ratio, the larger the number of turns required on the steering wheel from lock to lock. There is a limit to how low a ratio can be employed; too low a ratio will make it difficult for the driver to make a rapid change of direction in an emergency.

Many heavy commercial vehicles and the heavier type of luxury motor car have some form of power assistance for the steering. This enables the steering wheel to be turned with much less effort and also allows a higher gear ratio to be employed in the steering box so that the number of turns of the steering wheel from lock to lock is reduced. Power-assisted steering will be discussed later. In a brochure, issued by ZF Gears (Great Britain) — a prominent maker of steering gears — it is pointed out that legislation exerts a decisive influence on steering design.

It goes on to say: "Directives covering the inspection of steering systems for vehicles stipulate that the effort at the steering wheel must not exceed 250N. This applies when driving around a circle having a radius of 12m (see Figure 1). Starting from a straight-ahead position, the required steering wheel turn must be attained in four seconds, the respective speed should be approximately 10 km/h." This criteria ensures that steering does not become too heavy.

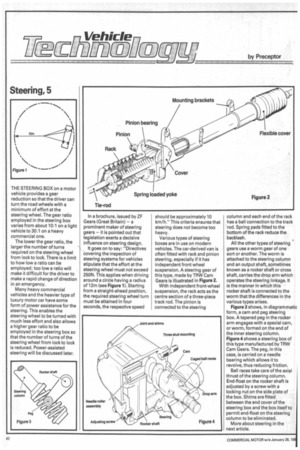

Various types of steering boxes are in use on modern vehicles. The car-derived van is often fitted with rack and pinion steering, especially if it has independent front wheel suspension. A steering gear of this type, made by TRW Cam Gears is illustrated in Figure 2.

With independent front-wheel suspension, the rack acts as the centre section of a three-piece track rod. The pinion is connected to the steering column and each end of the rack has a ball connection to the track 'rod. Spring pads fitted to the bottom of the rack reduce the backlash.

All the other types of steering gears use a worm gear of one sort or another. The worm is attached to the steering column and an output shaft, sometimes known as a rocker shaft or cross shaft, carries the drop arm which operates the steering linkage. It is the manner in which this rocker shaft is connected to the worm that the differences in the various types arises.

Figure 3 shows, in diagrammatic form, a cam and peg steering box. A tapered peg in the rocker arm engages with a special cam, or worm, formed on the end of the inner steering column. Figure 4 shows a steering box of this type manufactured by TRW Cam Gears. The peg, in this case, is carried on a needle bearing which allows it to revolve, thus reducing friction.

Ball races take care of the axial thrust of the steering column. End-float on the rocker shaft is adjusted by a screw with a locking nut on the side plate of the box. Shims are fitted between the end cover of the steering box and the box itself to permit end-float on the steering column to be eliminated.

More about steering in the next article.