Changes to anti-jack-knifing device

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

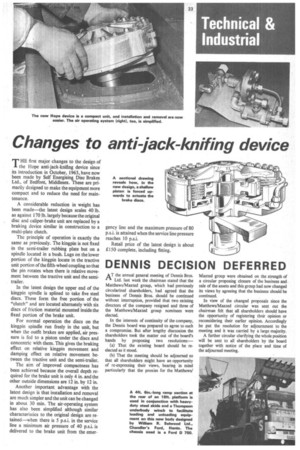

THE first major changes to the design of the Hope anti-jack-knifing device since its introduction in October, 1963, have now been made by Self Energising Disc Brakes Ltd., of Bedfont, Middlesex. These are primarily designed to make the equipment more compact and to reduce the need for maintenance.

A considerable reduction in weight has been made—the latest design scales 40 lb. as against 170 lb. largely because the original disc and caliper-brake unit are replaced by a braking device similar in construction to a multi-plate clutch.

The principle of operation is exactly the same as previously. The kingpin is not fixed in the semi-trailer rubbing plate but on a spindle located in a bush. Lugs on the lower portion of the kingpin locate in the tractive unit portion of the fifth-wheel coupling so that the pin rotates when there is relative movement between the tractive unit and the semitrailer.

In the latest design the upper end of the kingpin spindle is splined to take five steel discs. These form the free portion of the "clutch" and are located alternately with six discs of friction material mounted inside the fixed portion of the brake unit.

For normal operation the discs on the kingpin spindle run freely in the unit, but when the outfit brakes are applied, air pressure is fed to a piston under the discs and concentric with them. This gives the braking effect on relative kingpin movement and damping effect on relative movement between the tractive unit and the semi-trailer.

The aim of improved compactness has been achieved because the overall depth required for the brake unit is only 4 in. and the other outside dimensions are 12 in. by 12 in.

Another important advantage with the latest design is that installation and removal are much simpler and the unit can be changed in about 30 min. The air-operating system has also been simplified although similar characteristics to the original design are retained—when there is 5 p.s.i. in the service line a minimum air pressure of 40 p.s.i. is delivered to the brake unit from the emer gency line and the maximum pressure of 80 p.s.i. is attained when the service line pressure reaches 10 p.s.i.

Retail price of the latest design is about £150 complete, including fitting.