AMERICA "BUYS FHE BRUSSELS SHOW

Page 16

Page 17

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

By The Technical Editors A114.1-10LIGII, as "The Comniercial Motor explained last :Week in describing the British exhibits at the Brussels Show, 20 United Kingdom makes are on view, compared with 14 American, transatlantic commercial models exceed 60 per cent. of the total in the Exhibition. The reasim is that American makers show complete ranges of vehicles, whereas British manufacturers exhibit (mainly through agents) only a few types.

In certain instances, Americau companies exhibit on up to six stands, whilst some British vehicles are tucked away on trailer makers' stands. Transatlantic manufacturers have paid heavily for the privilege of dominating the stage.

Cost £66,000 to Stage

The Exhibition, which was opened quietly, last Saturday, by the Burgo

master of Brussels, and closes next Wednesday, is well organized, and the arrangement of the stands and the quality of the fittings compare closely with those of Britain's Commercial Motor Show, held last October. The cost of staging the Show was £66,000, and 38 miles of trimmings have been used. Much of this money has come from America.

The central hall is filled with cars from all countries, whilst commercial vehicles are shown in two flanking hails. Among the commercial exhibits are some of remarkable appearance and design, and in the earliest stages of .development.

We were interested to see the developments in the Miesse 1949 passenger, chassis, which follows the British trend of design by incorporating a fluid coupling drive, and compressed air-operated pre-selective epicyclic gearbox.

The engine and transmission components, not forgetting the Clayton Dewandre air operating system, are of British manufacture.' In most other respects, all the chassis on this stand follow the Continental practice of heavy construction. An all-Welded structure, the Miesse frame is of' generous proportions, reinforced by solid pressed-steel cross-members.

Shock absorbers are not included in the passenger-chassis suspension system, ntrt • but the springs are formed of plates 4f; in. wide and A 'in. thick, .hose at the rear being over 6 ft. long. They have fabricated hanger brackets forming a reservoir for the lubricant, which is fed to the springs, shackle pins and bushes. Torque reaction at the rear axle is restricted by rods which link each side of the axle casing to the spring hanger bracket. A double-reduction-ratio unit is housed in a large forged axle casing. The unladen single-decker passenger chassis weighs almost 51 tons.

Although fitted with this modern transmission system, an open transmission hand brake is still employed. In common with what seems to be general Continental practice, the Miesse chassis are all equipped with bonded rubber-to-metal centre bearings for the propeller shafts. The frame overhang is downswept in two stages, a feature which is claimed to afford extensive luggage accommodation. It would also appear to be expensive in tooling and other costs.

-Control valves for the compressedair braking and gear-operation systems are bolted directly under the floor plates, the rods bearing against the under side of the pedals. Most British vehicles have the steering-column housing bolted to the top and side of the frame member for rigidity, but the Miesse column is attached to an outrigger bracket at a point 8 ins, from the side member.

Both the Miesse goods chassis and a Mack 8-tonner, on an adjoining stand, have massive gearbox casings, which, bolted to the flywheel housing, are unsupported at the rear. This does not appear to he general practice, because most other exhibits have a rear

support for the gearbox. Continental operators whom we met at the Exhibition said that they preferred, for accessibility, to have the gearbox. positioned amidships in the chassis.

The Mack g-tonner is shown with a

Lanova-pattern six-eylindered oil engine.. A fabricated rear axle is used, which, compared with .the other components of the chassis, is of rela

tively light construction. The weight of this model as a chassis is 5 tons 1 cwt.

On the Other hand, the frame weight is redueed to a minimum in the 1949. Studebaker 4-5-tonner and other goods chassis of this make. A study of the frame and component construction Of the 5-tanner shows the marnifacturer to have tooled up for mass production ol

steel pressings, the engine-mounting brackets, frame, cross-members, spring brackets, petrol tank, bumper bars and engine base, all having been formed from light-steel pressings.

he cross-Members are made in • halves riveted together. A reversed L-shaped petrol tank is carried inside the frame and the frame side members are strengthened with an external flitch plate between the front and rear-spring hanger brackets.

Progressive Rear Suspension MoVement of the front springs is controlled by shock absorbers, whilst the rear springs are secured at the fore end and slide on a bracket at the rear. In conjunction with helper leaves, this method gives progressive action according to load. Rubber-bushed shackle pins are used.

In the Bendix braking system of the new Studebaker, a hydraulic cylinder and pipeline are employed between the pedal and vacuum hydraulic booster, displacing the conventional rods and levers. The propeller-shaft centre bearing is carried on a bracket' which is permitted to float on rubber bushings. , t , A novel feature of the White forwardcontrol 14i-tonner is the hinged cab, which, with the steering and other controls, is mounted on a sub-frame

attached to the chassis at its fore :end through.large•trunnion blocks and pins. A11the controls are universally jointed dr 'similarly arranged, so that the cab

nnaV he tipped forWard without . dis ...

connecting .any, of the units or com

ponents. •

By releasing a trip catch and revoivirw a handle half a turn, the cab, com..plete with Boor and controls, is tipped forward by power operation. An electric motor and bevel gearing supply the Power. 'During a demonstration, the cab was tilted forward in 15 secs. and returned to position in 11 sees. :Aecessibility of components iS -the

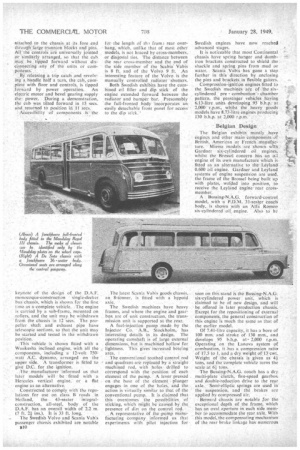

keynote' of the 'design of the D.A.F. monocaque-constructiOn single-decker bus.ehassis, which is shown for the first tnne a•cornplete vehicle. The engine is carried by a sub-frame. Mciunted on rollers, and the unit may he withdrawn froth the chassis in 12 secs. The propeller shaft arid exhaust pipe have teleseoPic sectionS. so that the unit may be started and tested in the withdrawn position.

,•This 'vehicle is shown fitted with a Waukeshainclinecl.engine. with all the components, including a 12-volt 70: watt A.C. dynamo, 'arranged On the .upPer side. A transformer is fitted to give. D.C. for the ignition.

The manufacturer informed us that later models' will be '.fitted' with a Hercules vertical engine, or a flat engine as an alternative;

Constructed to comply. with the regulations for use on class B roads 'in Holland, the 43-seater n tegra 1construction, all-steel, body of the D.A.F. has an overall width of 2.2 m. (7 ft. 21 ins.). It is 33 ft. long.

The Swedish Volvo and Scania Vabis passenger chassis exhibited are notable 310

fLi.r.the length of Eh,: [ram t rear overhang..which, unlike that of most other models, is not braced by crOss-members.. or diagonal ties. The distance between the rear cross-Member and the end Of the side member of the Scabia' Vabis is 8 ft. and of the Volvo 9 .ft. An interesting feature of the Volvo is the manually controlled radiator 'shutters.

Both Swedish exhibit S have the combined oil filler and (lip 'stick of the engine extended •forward between: the radiator and bumper bar. Presumably the full-fronted body 'incorporates' an easily detachable front panel for access to the dip stick.'

The latest Scania Vabis goods,chassis.an. 84c:inner, is fitted with a hypoiti axle. • .

The Swedish machines have heavy frames, and where the engine and gear= box are of unit construction, the transmission unit is supported at the rear.

A fuel-injection pump ,made by the Injector Co. A.B., Stockholm,' has interesting details in _its design. The operating camshaft is of large external dimensions, but is machined' holloW for lightness. This gives -increased bearing area. : The conventional toothed control rod and quadrant.are replaced 'by a straight machined rod, with holesdrilled to correspond with the poSition Of each element of the ptimp. A lever pressed on the base of the 'element : plunger engages in one •of the 'holes, and the action is virtually similar td that Of the conventional pump. It is claimed that this • overdomes the possibilities of sticking, which might be cnuSed by the presence of dirt on the control. rod. A representative 'of the..prtmp manufacturing Company inforMed us that experiments with pilot injection for

Swedish engines have now reached advanced stages. It is noticeable that most Continental chassis have spring hanger and 'dumbiron brackets constructed to shield the shackle and spring pins from mud of water. Scania Vabis has gone a step further in this direction by .enclosing the pins and brackets in flexible gaiters.

Compression-ignitidn engines fitted to the Swedish machines ate of the sixcylindered pre combustion chandler pattern, the passehger vehicles haying 6.13-litre units developing 95 b.h.p: at 2,000 r.p.m., whilst the heavy goods models have 8.73 -litre engines prodticin-g 130 b.h.p. at 2,000 r.p.m. •

Belgian Design

The Belgian exhibits mOst]y have e'nginos and Other Main Coniposients of British, American or French manufacture. Miesse models are shown With Gardner six-cylindered oil engines; whilst the Brossel concern has an nil engine of its 'own Manufacture which is fitted as _an alternative to the Leyland 0.600 oil engine: Gardner and Leyland systems of engine suspension are used, the frame of the Brossel being built pp with plates, welded into position, to receive the Leyland engine• rear croismember.

A Bussing-N.A.G, forward-control model, with a P.D.M. :31-seater bOach body, is shown with an Alf; Romeo

six-cylindered engine. Alm') `t-ci be seen on this stan.d is the Bussing-N.A.G. -six-cylindered power . unit`, which is Clainted to be of new design, and will be offered in later Production chasSis. Except for the repoSitiOning of extetnal Components, the general construction of this engine is much the same as that of the earlier model.

" Of 7.41-litre capacity, it has a•bore of 100 Mm: and stroke of 130 mm., and develops 95 b.h.p. at 2,000 r.p.m. Operating on the Lanova system of combustion, it has a corripression ratio of 17.5 to,1, and a dry.weight.of'13:cwt. Weight of :the ChaSsis is given aS 4i WM, and the complete vehicle turns the scale at 61 tons. • 'The Bussing-N.A.G. coach has a dry. .multi-plate clutch, five-speed gearbox and dotNe-reduction drive to the 'rear axle., Semi-elliptic springs are Used in the suSpension4 and the brakes are applied by compressed air. •

Bernard Chassis are notable fon the exceptional depth of the frame, which has: an oval aperture in each side member to accommodate the rear axle. With this model, the compensating mechanism of the rear brake linkage has numerous fork ends, pins and bushes, which are open to dirt or water. In the course of usage considerable lost movement might occur.

A 1949 range of vehicles exhibited by Unic has a slightly modified frontal styling, but in most other respects the vehicles remain unchanged. Standardization is a feature of the range, the same engine, gearbox and other components being common to the 8-ton load carrier, and the 10-ton and 13-ton tractors. Their frames are heavy all-' welded structures.

Compared with the Bernard and other Continental chassis, the frames and braking arrangements of American vehicles are of exceptionally light construction. American frames are usually . of pressed steel, with the cross-members cold-riveted into position. The vacuum servo motor and compressed-air operating cylinders are formed from light steel pressings, the operating mechanism being of the diaphragm pattern.

Two-Speed Axles

Many of the heavier models have two-speed axles, selection of ratio being by vacuum or compressed air. The multi-purpose Jeep is shown with a variety of agricultural attachments and with a delivery-van body. As a van, it has a single drive to the rear axle and a steering-column gear selector.

The Dodge "route van" makes its first European appearance at the Brussels Show. Its unique design attracted attention, but we were disappointed to find it had a friction-clutch drive in the ' transmission, and no electro-hydraulic brake. This form of brake is shown fitted to the N.0 B. 1-ton battery-electric chassis. The • route van" was described in "The Commercial Motor" .dated December 31, 1948.

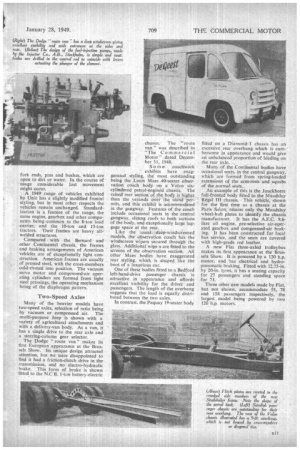

So ma coachwork exhibits have exaggerated styling, the most outstanding being the Louis Maes 40-seater observation coach body on a Volvo sixcylindered petrol-engined chassis. The raised' rear section' of the body is higher than the .veranda over the stand permits, and this exhibit is accommodated in the gangway. Features of the coach include occasional seats in the central gangway, sliding roofs to both sections of the body, and exceptionally large luggage space at the rear. Like the .usual—deep-vviridscreened models, the -observation coach has the windscreen wipers secured through the glass. Additional wipers are fitted to the screens of the observation section. All other Maes bodies have exaggerated rear styling; which is shaped like the boot of a luxurious car.

One of these bodies fitted to a Bedford left-hand-drive passenger chassis is attractive in appearance and affords excellent visibility for the driver and passengers. The length of the overhang suggests that the load is equally distributed between the two axles.

In contrast, the Paquay 19-seater body fitted on a Diamond-T chassis has an excessive rear overhang which is cumbersome in appearance and would give an unbalanced proportion of loading on the rear axle. ..

Many of .the-Continental bodies have occasional seats, in the central gangway, which are formed from spring-loaded extensions of the arm-rests and .squabs of the normal seats..

An example of this is the Jonckheere full-frOnted body fitted to the Matidslay .Rgal. 111 chassis. This vehicle, shown for the first time as a chassis at the Paris Salon, retains only the Maudslay wheel-hub plates to identify the chassis manufacturer. It has the A.E.C. 9.6litre oil engine, pre-selective air-operated gearbox and compressed-air braking. It has been constructed for local bus service, and the seats are covered with high-grade red leather.

A new Fiat three-axIed trolleybus makes its first appearance at the Brussels Show. It is powered by a 120 h.p. motor, and has electrical and hydropneumatic braking. Fitted with I2.75-in. by 20-in. tyres, it has a seating capacity for 27 passengers and standing space for 71.

Three other new models made by Fiat, but not shown, accommodate 55, 78 and 158 passengers respectively, the largest model being powered by two 120 h.p motors.