Stabilizing by Cross-coupled Shock Absorbers

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

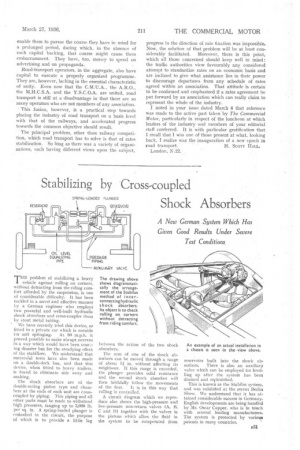

rE problem of stabilizing a heavy vehicle against rolling on corners, without detracting from the riding comfort afforded by the suspension, is one of considerable difficulty. It has been tackled in a novel and effective manner by a German engineer who employi two powerful and well-built hydraulic shock absorbers and cross-couples them by stout metal tubing.

We have recently tried this device, as fitted to a private car which is notable

1.1.• soft springing. At 80 m.p.h. it proved possible to make abrupt swerves in a way which would have been cour,;ing disaster but for the steadying effect of the stabilizer. We understand that successful tests have also been made on a double-deck bus, and that this device, when fitted to heavy trailers, is found to eliminate side sway and snaking.

The shock absorbers are of the double-acting piston type and chambers at the ends of each unit are crosscoupled by piping. This piping and all other parts must be made to withstand high pressures, ranging up to 3,000 lb. per sq. in. A spring-loaded plunger is embodied in the circuit, the purpose of which is to provide a little lag

between the aclion of the two shock absorbers.

The arm of one of the shock absorbers can be moved through a range of about /i in. without affecting its neighbour. If this range is exceeded, the plunger provides solid resistance and the second shock absorber will then faithfully follow the movements of the first. It is in this way that rolling is controlled.

A circuit diagram which we reproduce also shows the high-pressure and low-pressure non-return valves (A, B, C and D) together with the valves in the pistons which allow the fluid in the system to be recuperated from reservoirs built into the shock ab

sorbers. There is also an auxiliary valve which can be employed for levelling up after the system has been drained and replenished.

This is known as the Stabilus system, and was exhibited at the recent Berlin Show. We understand that it has attained considerable success in Germany. English developments are being handled by Mr. Oscar Cupper, who is in -Witch with several leading manufacturers. The system is protected by various patents in many countries.