BRILLIANT ZFORMANCE BY A I HT 4x4

Page 46

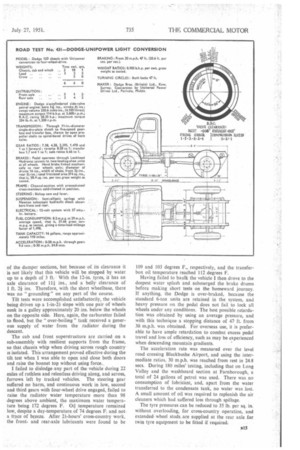

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

B) L. J. CO

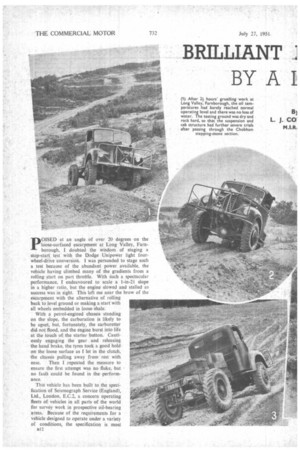

pOISED at an angle of over 20 degrees on the loose-surfaced escarpment at Long Valley, Farnborough, I doubted the wisdom of staging a stop-start test with the Dodge Unipower light fourwheel-drive conversion. I was persuaded to stage such a test because of the abundant power available, the vehicle having climbed many of the gradients from a rolling start on part throttle. With such a spectacular performance, I endeavoured to scale a 1-in-2i slope in a higher ratio, but the engine slowed and stalled as success was in sight. This left me near the brow of the escarpment with the alternative of rolling back to level ground or making a start with all wheels embedded in loose shale.

With a petrol-engined chassis standing on the slope, the carburation is likely to be upset, but, fortunately, the carburetter did not flood, and the engine burst into life at the touch of the starter button. Cautiously engaging the gear and releasing the hand brake, the tyres took a good hold on the loose surface as I let in the clutch, the chassis pulling away from rest with

ease. Then I .repeated the measure to ensure the first attempt was no fluke, but no fault could be found in the perform ance. .fer This vehicle has been built to the specification of Seismograph Service (England), Ltd., London. E.C.2, a concern operating fleets of vehicles in all parts of the world for survey work in prospective oil-bearing areas. Because of the requirements for a vehicle designed to operate under a variety of conditions, the specification is most

B12

comprehensive. The vehicle had to be light because many local-built bridges are constructed for bullock carts and like traffic, abundant power and large-section tyres were essentials for negotiating soft sand and steep banks, and yet the complete assembly had to be extremely robust to withstand severe cross-country work or for operation across the washboard surfaces of the deserts.

All existing four-wheel-drive chassis were examined, but were rejected for various reasons, including being under-powered or too heavy for operation in any particular area. The Dodge 6-ton, left-hand-drive, shortwheelbase chassis with the 114 b.h.p., six-cylindered, side-valve engine, fulfilled the role for lightness and power, and its weight distribution was right for cross country operation. With a wheelbase length of 9 ft. 11 ins., and front-wheel drive, this model is virtually potted power.

Fitted to the Dodge 6-tonner is a five-speed gearbox

with a super-low ratio of 7.58 to 1, which is ideal for crawling the chassis out of difficulties. Behind the gearbox there is a transfer case, of a type used in the UMpower tractors, mounted separately in the chassis. This transfer case is resiliently supported at three points 50 that any movement of the frame members is not communicated to the casting. Ratios of direct drive and 1.7 to 1 are provided through helical gearing carried in the transfer box, four-wheel drive being engaged automatically when the indirect gear is selected. This prevents the driver from boggingdown the rear wheels when driving on only one axle where ground conditions demand four-wheel drive and, at the same time, protects the rear axle driving shafts against excessive torque.

The Unipower front axle is square in section and incorporates a spiral-bevel drive of the same pattern as used in the rear axle. Drive to the front wheels is transmitted through fully floating shafts. and Rzeppa constant-velocity joints which are now made in this country. With a front-wheel turning arc of 60 degrees, the unit has a turning circle of 47 ft. on both locks.

Modifications have been made in the suspension, springs of lighter capacity being fitted in conjunction with Newton type 1400 hydraulic shock absorbers.

Although it is unlikely that this vehicle will meet with any difficulties during cross-country running, it is equipped with a forward-mounted winch by HandsEngland Oiltields Equipment, Ltd., for self-recovery. The power-take-off drive is arranged so that the wheels can be driven while the winch is working to assist during a recovery operation.

Much of the work done with this chassis will be in tropical areas, so to improve the cooling the fan is surrounded by a shroud which is attached to the engine, and connected to the radiator by a canvas gaiter. The cab, bonnet and radiator are carried on the Dodge standard sub-frame, with flexible mounting, supported independently of the engine and chassis. Additional cooling arrangements include a opening screen to the cab and provision for a shield to be fitted over the roof.

Special precautions have to he taken with vehicles which are operated near explosive charges, and one safeguard is to mount the petrol tank in the cab. The battery crate has been moved from the side of the frame and sunk below floor level under the driver's seat. This prototype model will be equipped with a drilling rig, and all units on the frame are, therefore, exposed to damage. Therefore, the Lockheed hydraulic brake unit has been moved to a position below the cab for protection and fitted with a breather pipe.

Additional features of the vehicle include a full-width bench-type seat for the driver and two crew, and a thick Dunlopillo lining to the roof which serves the dual purpose of insulation and protection when on cross-country work. The engine has a closed-circuit breathing system with oil-bath air cleaners at the filler and induction pipes. A hard nose is fitted to the front-axle final-drive housing for added protection. Certain difficulties have been experienced in maintaining compensated-voltage-control electrical systems in the field, so a third-brush dynamo has been specified by the operator for all vehicles in the fleet. A special, lightweight brush guard developed by this concern is fitted in front of the winch. It takes the form of an 1-section main beam at the base with a tubular frame. second.

Weight on Front Axle Complete with cab and winch, the chassis weighs 2 tons 18i cwt., of which 67 per cent. is supported by the front axle. The load was imposed with its centre of gravity in correct relation to the drilling rig, and of the chassis's 6 tons 6 cwt. running weight, the distribution was 49 per cent, on the front axle. With single tyres at both axles, an equally proportioned load is ideal for tyre loading, and for cross-country performance.

Collecting the vehicle from the Unipower works near London, I started a consumption test along the Western Avenue, and drove to Farnborough via Southall, Staines 814 and Egham, where there were the usual traffic delays which are found in most small towns. A clear run along the South West Road provided the opportunity of trying the chassis at speed, and 1 accelerated to over 50 m.p.h., without finding evidence of steering wander.

Change Down Early

It is some time since I have had a petrol-engined vehicle of this type on test, and, initially,! let the engine speed fall too low before changing gear. With a powerto-weight ratio of almost 1 b.h.p. per cwt. and good torque, the Dodge-Unipower pulls well at low speed, but to get the best performance on gradients, such as Bagshot Hill, it is preferable to make an early change. After 40 miles' running, I stopped to refuel, and the consumption figure worked out at the rate of 8.2 m.p.g. at an average speed of 29 m.p.h.

Following the consumption trial, I drove to the washboard section of the Ministry of Supply Proving Ground, and spent 21 hours endeavouring to find a weakness in the chassis. Because of the short wheelbase and large tyres inflated to 45 lb. per sq. in., it was rather uncomfortable travel, but apart from dislodging the oil-bath air cleaner from the engine filter and loosening a floor plate, the vehicle came through 24 miles of the most rigorous suspension test work to which a vehicle can be subjected in this country. On two occasions, the transfer-box gear slipped out of mesh, but considering the severe punishment meted out to the chassis as a whole and the whip of the frame during spring periodicity, this slight breach is easily forgiven.

My next attempt to foil the vehicle was on the Farnborough slopes, but because of the amplesectioned tyres plus high power, and low-ratio gearbox, it takes rather more than a 1-in-21 incline to stop a model of this calibre. There is a point, however, where although there may be sufficient traction, the state of the ground will defeat climbing a very steep hill. Such was the case on the I-in-2f incline slope where the subsoil had been eroded by rain, and the test chassis finally came to a halt with all four wheels spinning. Possibly a lower tyre-pressure might have provided just that little extra grip required, or, perhaps, had the tyres been less worn, the attempt might have been more successful. This could have been a timely moment to test the self-recovery gear, but, unfortunately, the winch had not been connected.

Just to prove there was adequate power, the vehicle was subjected to stop-start tests on all the gradients of up to 1 in 2f severity, and apart from using full throttle for the initial take-off, I was able to relax pressure on the pedal once the wheels were turning. I was gratified to find that the hand brake held the chassis and its load stationary while these tests were being carried out.

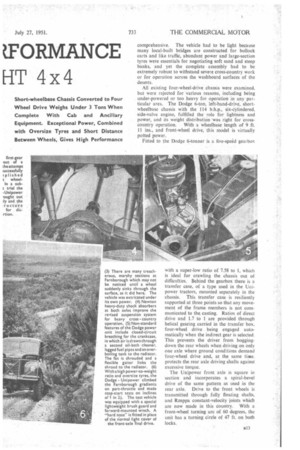

Long Valley was practically dry, therefore, the crosscountry work comprised more suspension and climbing tests.There were a few occasions when the forwardmounted winch ploughed through muddy water in some

of the damper sections, but because of its clearance it is not likely that this vehicle will be stopped by water up to a depth of 3 ft. With the 12-in. tyres, it hasan axle clearance of 111 ins., and a belly. clearance of 1 ft. 21 ins. Therefore, with the short wheelbase, there was no "grounding" on any part of the course.

Tilt tests were accomplished satisfactorily, the vehicle being driven up a 1-in-21, slope with one pair of wheels sunk in a gulley approximately 20 ins, below the wheels on the opposite side: Here, again, the carburetter failed to flood, but the " over-boiling " tank received a generous supply of water from the radiator during the descent.

The cab and front superstructure are carried on a sub-assembly with resilient supports from the frame, so that chassis whip when driving across rough country is isolated. This arrangement proved effective during the tilt test when I was able to open and close both doors and raise the bonnet top without using force.

failed to dislodge. any part of the vehicle during 22 miles of ruthless and relentless driving along, and across, furrows left by tracked vehicles. The steering gear suffered no harm, and continuous work in low, second and third gears with four-wheel drive engaged, failed to raise the radiator water temperature more than 98 degrees above ambient, the maximum water temperature being 172 degrees F.. Oil -temperature remained low, despitea day-temperature of 74 degrees F. and-not a trace of breeze. After 2i-hours' cross-country work, the frontand rear-axle lubricants were found to be 109 and 103 degrees F., respectively, and the transferbox oil temperature reached 112 degrees F.

Having failed to baulk the vehicle I then drove to the deepest water splash and submerged the brake drums before making short tests on thehomeward journey. If anything, the Dodge is over-braked, because the standard 6-ton units are retained in the system, and heavy pressure on the pedal does not fail to lock all wheels under any conditions. The best possible retardation was obtained by using an average pressure, and with this technique a stopping distance of 47ft. from 30 m.p.h. was obtained. For overseas use, it is preferable to have ample retardation to combat excess pedal travel and loss of efficiency, such as may be experienced when descending mountain gradients.

The acceleration rate was measured over the level road crossing Blackbushe Airport, and using the intermediate ratios, 30 m.p.h. was reached from rest in 24.8 secs. During 180 miles' testing, including that on Long Valley and the washboard section at Farnborough, a total of 24 gallons of petrol was used. There was no consumption of lubricant, and, apart from the water transferred to the condensate tank, no water was lost. A small amount of oil was required to replenish the air

cleaners which had suffered loss through spillage. .

The tyre pressures can be reduced to 35 lb. per sq. in. without overloading, for cross-country operation, and extended wheel studs.are supplied at the rear axle for twin tyre equipment to be fitted if required.