DEVELOPMENTS IN PASS] R VEHICLE COACHWORK.

Page 16

Page 17

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

IT IS a striking and pleasing fact that improvements in the construction of bodies for passenger vehicles are occurring so rapidly that it is quite a difficult matter to deal with them without the possibility of incurring criticism for devoting to them too much of the reading matter contained in this journal. There is no doubt that vast strides have been made during the past few years, and the modern bus or coach is rapidly becoming the rival of the privatu car in the comfort which it provides for its passengers, although; as we have pointed out editorially, there are many public passengercarrying vehicles on the road which still require attention in certain details in order to promote extra comfort.

One of the most interesting of the vehicles which have been produced recently is the new type of oneman-controlled bus built by the Liverpool Corporation, and which is to be put into service almost immediately over the route between Hunts Cross Station and Gateacre Station, on the outskirts of the city.

Carrying the Body on Auidiiary Springs.

The most notable feature of this vehicle is that the bodywork is not supported directly on the chassis frame, but is carried by a series of auxiliary • springs which are intended to damp out road shocks transmitted to the chassis through the main springs. This is, of course, not the first effort which has been made in this direction, for a very satisfactory device, embodying laminated springs, was brought out some time ago by Messrs. Strachan and Brown, and is being used in many parts of the country. However, in this particular vehicle the supplementary springing is carried out in rather a different manner.

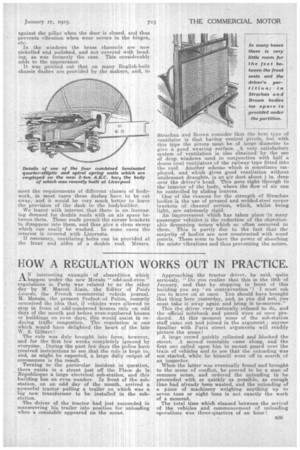

There are two sets of four coil springs at each side of the body. In conjunction with each set of coil springs is a quarter-elliptic spring of the laminated type. Each of these laminated springs is held by a bracket bolted to a side member of the chassis frame, and it projects at an angle of slightly less than 45 degrees from the line in the side member. The fixing is somewhat unusual. At the forward end of the bracket it is secured by a clip of the usual type, but at what may be termed the stub end of the spring, the upper two leaves are bent up at right angles to form a lip for the square head of a bolt which passes down through the spring and the bracket, and is provided with a coil-compression spring at its lower end.

The outer end of each spring passes into a bracket B32

attached to the body, the weight of that part of the body being taken by a hanger bolt passing through the spring end and also provided with a coil-compression spring. The remaining two coil springs of each set are of different -sizes, the larger being situated above the bracket support for the quarterelliptic spring, whilst the smaller is carried below this bracket, the two being secured together by a bolt, the head of which passes through a bracket on the body and the shank through the spring bracket. Thus, the upper coil spring assists in taking the load, whilst the lower acts as a recoil damper.

The advantage of splaying the laminated springs in the manner described is that the virtual spring base is increased and, consequently, any rolling tendency is diminished. Each quarter-elliptic spring is about 2 ft. in length. The vehicle on which this springing is employed is a 22-seater on a 2-ton A.E.C. chassis.

A feature of the body construction is that, whilst the bacc seat runs the entire width of the vehicle, the windows at the rear are fastened by a single catch, which, when released in case of emergency, enables them to be swung outwards.

On the near side, between the last of the double seats and the rear seat, is the emergency door. This works in conjunction with two steps, which fall into position when the door is opened and fold up when it is closed.

The roof is built on the clerestory principle, which affords greater headroom (this being actually 6 ft. 3 ins.). The side windows are fixed, but glass ventilators are provided in the roof. At the front portion of the body, at the side of the driver's partition, is a sliding door to prevent draughts, as no door is provided to the driver's cab.

Considerable attention is now being turned to the question of utilizing covered-top decks on large buses. Our readers will know that some of these have already been authorized for use in London,

and others are actually in everyday use in other towns.

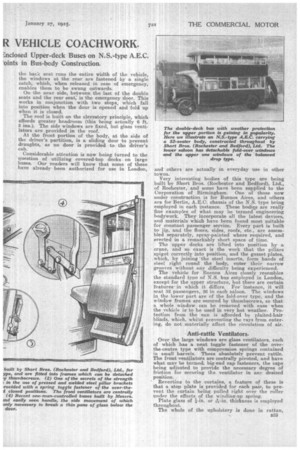

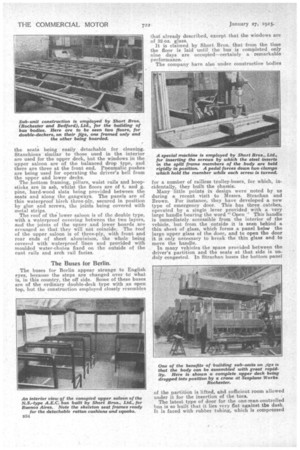

Very interesting bodies of this type are being built by Short Bros. (Rochester and Bedford), Ltd., of Rochester, and some have been supplied to the Corporation of Birmingham. One of those now under construction is for Buenos Aires, and others are for Berlin, A.E.C. chassis of the N.S. type being employed in each instance. These bodies are really fine examples of what may be termed engineering bodywork. They incorporate all the latest devices, and materials which have been found most suitable for constant passenger service. Every part is built to jig, and the floors, sides, roofs, etc., are assembled separately, spray-painted where required, and erected in a remarkably short space of time. The upper decks are lifted into position by a crane, and so exact is the work that the pillars spigot correctly into position, and the gusset plates, which, by joining the steel inserts, form bands of steel right round the body, enter their narrow grooves without any difficulty being experienced. The vehicle for Buenos Aires closely resembles the standard type of N.S. bus employed in London, except for the upper structure, but there are certain featuresin which it differs. For instance, it will seat 52 passengers, 26 in each saloon. The windows in the lower part are of the fold-over type, and the window frames are secured by thumbscrews, so that a whole window can be removed with ease when the vehicle isto be used in very hot weather. Protection from the sun is afforded by plaited-hair blinds, which, whilst preventing the rays from entering, do not materially affect the circulation of air.

Anti-rattle Ventilators.

Over the large windows are glass ventilators, each of which has a neat toggle fastener of the overthe-centre type with compression springs contained in small barrels. These absolutely prevent rattle. The front ventilators are centrally pivoted, and have what may be termed, big-end cap fasteners, the caps being adjusted to provide the necessary degree of friction for securing the ventilator in any desired position. Reverting to the curtains, a feature of these is that a stop plate is provided for each pair, to prevent the curtain being pulled right over the roller under the effects of the winding-up spring. Plate glass of I-in. or A-in. thickness is employed throughout.

The whole of the upholstery is done in rattan, B33 the seats being easily detachable for cleaning. Stanchions similar to those used in the interior arc used for the upper deck, but the windows in the upper saloon are of the balanced drop type, and there are three at the front end. Pneumatic pushes are being used for operating the driver's bell from the upper and lower decks.

The Ibottom framing, pillars, waist rails and hoopsticks are in ash, whilst the floors are of t. and g. pine, hard-wood slats being provided between the seats and along the gangways. The panels are of thin waterproof birch three-ply, secured in position by glue and screws, the joints being covered with metal strips.

The roof of the lower saloon is of the double type, with a waterproof covering between the two layers, and the joints of the upper and lower boards are arranged so that they will not coincide. The roof of the upper saloon is of three-ply, with front and rear ends of sheet aluminium, the whole being covered with waterproof linen and provided with moulded water-chutes fixed on the outside of the cant rails and arch rail facias.

The Buses for Berlin.

The buses for Berlin appear strange to English. eyes, because the steps are changed over td what is, in this country, the off side. Some of these buses are of the ordinary double-deck .type with an open top, but the construction employed closely resembles

that already described, except that the windows are of 32-oz. glass.

It is claimed by Short Bros. that from the time the floor is laid until the bus is completed only nine days are occupied—certainly a . remarkable performance.

The company have also underconstruction bodies for a number of railless trolley-buses, for which, incidentally, they built the chassis.

Many little points in design were noted by us during a recent visit to Messrs. Strachan and Brown. For instance, they have developed a new type of emergency door. This has three catches, operated by a single lever provided with a very large handle bearing the word " Open? This handle is immediately accessible from the interior of the vehicle, but from the outside it is seen behind a thin sheet of glass, which forms a panel below the large upper glass of the door, and to open the door it is only necessary to break the thin glass and to move the handle.

In many vehicles the space provided between the driver's partition and the seats at that side is unduly congested. In Strachan buses the bottom panel of the partition is lifted, and sufficient room allowed under it for the insertion of the toes.

The latest type of door for the one-man-controlled bus is so built that it lies very fiat against the dash. It is faced with rubber tubing, which is compressed against the pillar when the door is closed, and thus prevents vibration when wear occurs in the hinges} etc.

In the windows the brass channels are now nickelled and polished, and not covered with beading, as was formerly the case. This considerably adds to the appearance. It was pointed out that on many English-built chassis dashes are provided by the makers, and, to meet the requirements of different classes of bodywork, in most cases these dashes have to be cat away, and it would be very much better to leave the provision of the dash to the bodybuilder.

We learnt with interest that there is an increasing demand for double roofs with an air space between thin. These roofs permit the corner brackets to disappear into them, and thus give a clean sweep which can easily be washed. In some cases the interior is covered with Lincrusta.

If necessary, ventilating holes can be provided at the front and sides of a double roof. Messrs. Strachan and Brown consider that the best type of ventilator is that having central pivots, but with this type the pivots must be ef large diameter to give a good wearing surface. ,A very satisfactory system of ventilation is also obtained by the use of drop windows used in conjunction with half a dozen cowl ventilators of the railway type fitted into the roof. Another scheme which is sometimes employed, and which gives good ventilation without unpleasant draughts, is an air duct about I in. deep over the driver's head. This goes right through to the interior of the body, where the flow of air can be controlled by sliding louvres. One of the reasons for the strength of Strachan bodies is the use of pressed and welded-steel corner brackets of channel section, which, whilst being light, are extremely rigid. An improvement which has taken place in many passenger vehicles is the reduction of the objectionable drumming noises which so often occurred in them. This is partly due to the fact that the majority of bodies are now constructed with wood panels. These seem to have the power of absorbing the miribr vibrations and thus preventing the noises.