Mechanized Methods Speed Up Parcels Traffic

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

THOSE districts in Surrey which surround Kingston have for many years been served by Carter Paterson and Co., Ltd., from its depot at Manorgate Road, Norbiton. This was originally designed when the carrier relied chiefly upon horsed transport, but it was made suitable for motor , traffic in 1913.

Since that time there has been a large expansion of traffic, with the result that a depot designed for more motor vehicles and for the speedy handling of goods by modern mechanized conveyer systems has become imperative. Accordingly, in the company's new depot at Glenbuck Road, Surbiton, no provision whatsoever has been made for horses, as all the districts will be served by motors, whilst up-to-date methods of handling have been installed.

The problem of finding a site which would be sufficient for the present and yet adequate for future developments, presented difficulties, but eventually an area of nearly 2/ acres, adjoining the Southern Railway's main line at Surbiton, was secured. Here the company's high standard of road service can be maintained and, for the future, an easy means of contact has been established for the exploitation of the possibilities of road-rail co-ordination.

The new depot has a pleasing exterior, spacious yards free of obstruction, and it provides for • greater

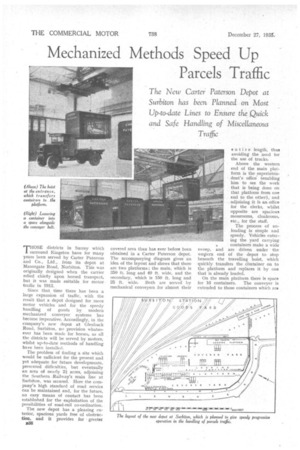

38 covered area than has ever before been obtained in a Carter Paterson depot. The accompanying diagram gives an idea of the layout and shows that there are two platforms; the main, which is 350 ft. long and 40 ft. wide, and the secondary, which is 150 ft. long and 25 ft. wide. Both are served by mechanical conveyers for almost their entire length, thus avoiding the need for the use of trucks.

Above the western end of the main platform is the superintendent's office (enabling him to see the work that is being done on that platform from one end to the other), and adjoining it is an office for the clerks, whilst opposite are spacious messrooms, cloakroms, etc., for the staff.

The process of unloading is simple and speedy. Vehicles entering the yard carrying • containers make a wide sweep, and are driven under the weVena end of the depot to stop beneath the travelling hoist, which quickly transfers the container on to the platform and replaces it by one that is already loaded.

On the main platform there is space for 10 containers. The conveyer is extended to those containers which are being unloaded, thus the incoming traffic is quickly transferred to the appropriate loading docks. Opposite the containers is " backing-up " space for the vehicles that have made collections in the area served by the 'depot. All incoming goods arrive at the same end of the platform, and are sorted and transferred either to an outgoing container or on to the conveyer belt for transfer to the delivery vans.

Space for loading delivery vans commences at the end of the travelling hoist on one side of the platform, and just within the covered ,yard on the other. Altogether provision has been made for 66 district delivery vans, 48 on the main and the remainder on the secondary platform, which is singlesided and parallel to the main platform, to which it is connected by the conveyer belt. The conveyer on this platform is against the wall, whilst that on the main platform is in the centre.

The conveyers are of the sliding-belt type—a continuous balata band sliding on steel plates with •rollers at intervals. To avoid unnecessary labour the belt is raised a distance of only a few inches above the floor of the platform. An additional feature is the hard wood slide by which. the "take-off ". shock at the ends or intermediate places is minimized. The transfer of goods••from one conveyer to another is done by means of gear-graduated, poweroperated rollers, In all there will be 687 ft. of conveyers.

Surbiton is the eighth depot of the company where the handling of traffic is'Mechanized. One of the most interesting features of this' depot, when completed, will be the underground conveyer for transferring traffic to the company's railway siding. The siding will form part of `the road-rail coordination schemes. In addition to the facilities for mechanical transfer, there will he space at the sliding platform for vehicles to be backed up to collect or deliver direct loads—the intention being, of course, to dispense With (limbic handling,